Victor Xu Page 66 12 Jan. 2011

Copyright 2011 © Shenzhen Runtianzhi Image Technology, Co., Ltd.

http://www.floradigital.com

duty grease on contact surfaces. Raster strip should be clean with IPA moisten clean cloth. Both

should be done weekly.

Timing belts should be check monthly for traces of damages, misalignment and loose

tension.

Carriage timing belt tension can be adjusted thru two bolt tension adjuster at the left end of

the beam. The X-axis servomotor timing belt and print head wiping mechanism tension and can be

adjusted by loosening their respective mounting brackets.

7.4.2 Maintenance of Y-axis

Beam Worm gears, support shifter, worm gear center support, guide rails and slider bearing

should be clean and applied with enough light duty grease on contact surfaces. Should be done

weekly.

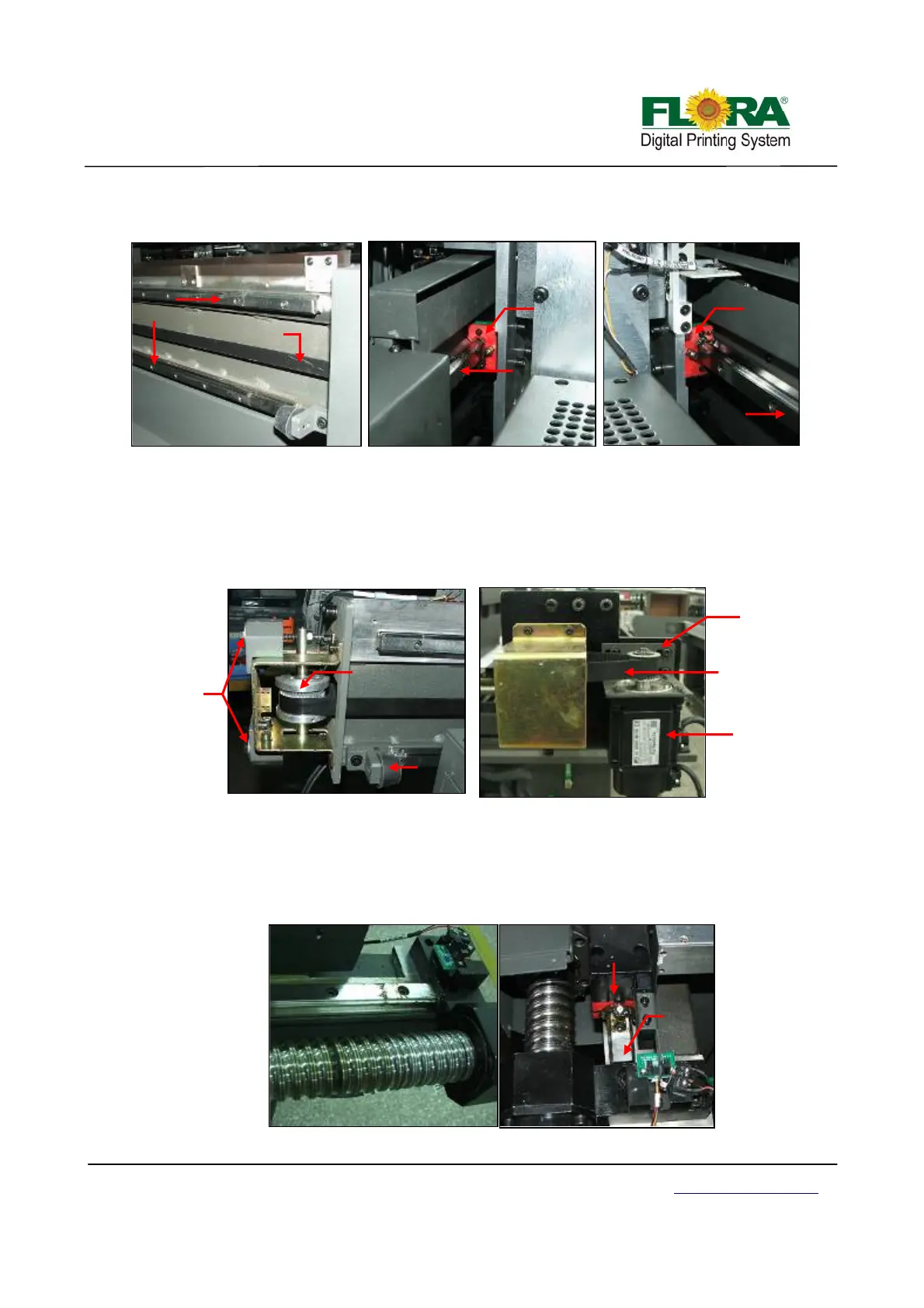

Carriage Right Slider bearing

Slider

bearing

Guide Rail

Guide Rail and Raster Strip

Guide

Rails

Raster Strip

Carriage

Timing Belt

Carriage Left Slider bearing

Slider

bearing

Guide Rail

Worm

gear

Worm Gear and Guide Rail

Worm gear

Guide Rail

Slider

Bearing

Guide

Rail

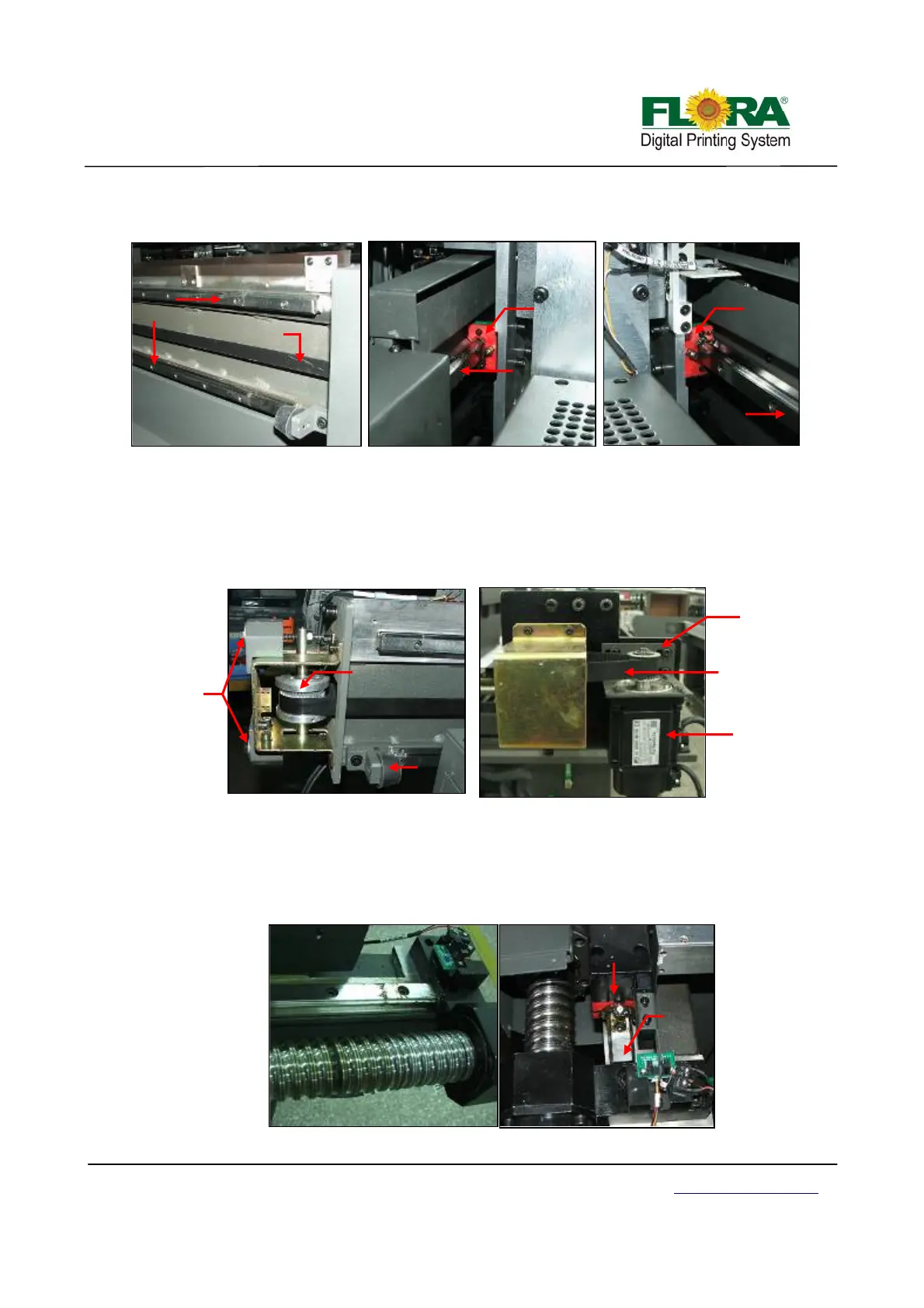

X-axis Servomotor

Adjust tension

here

Timin

Belt

Servomoto

Carriage Timing Belt Tension Adjuster

Gear Pulley

Carriage Timing Belt

Adjust

tension

here

Rubber

Bumper

Loading...

Loading...