QUANTUM

™

HD COMPRESSOR CONTROL PANEL

MAINTENANCE

090.040-M (NOV 2016)

Page 109

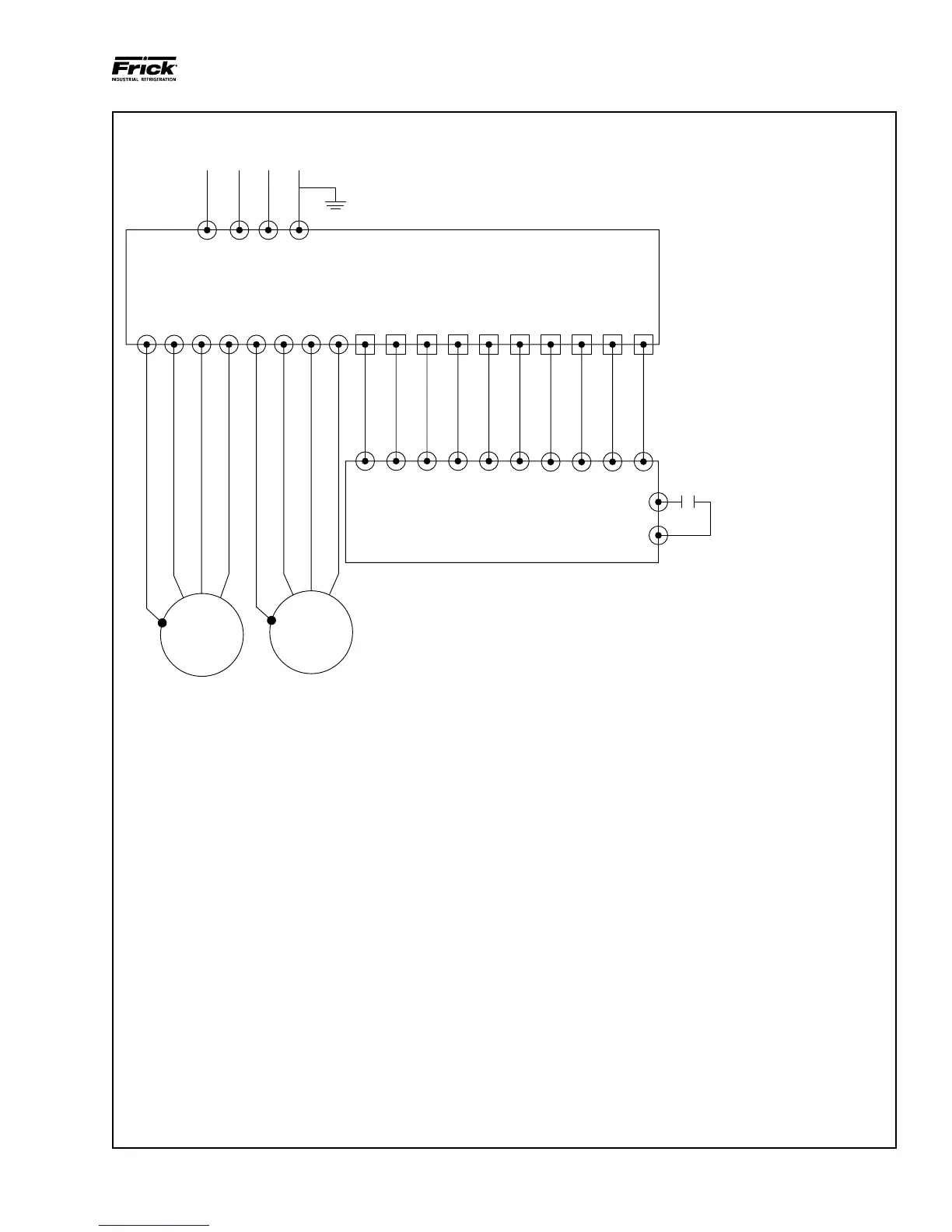

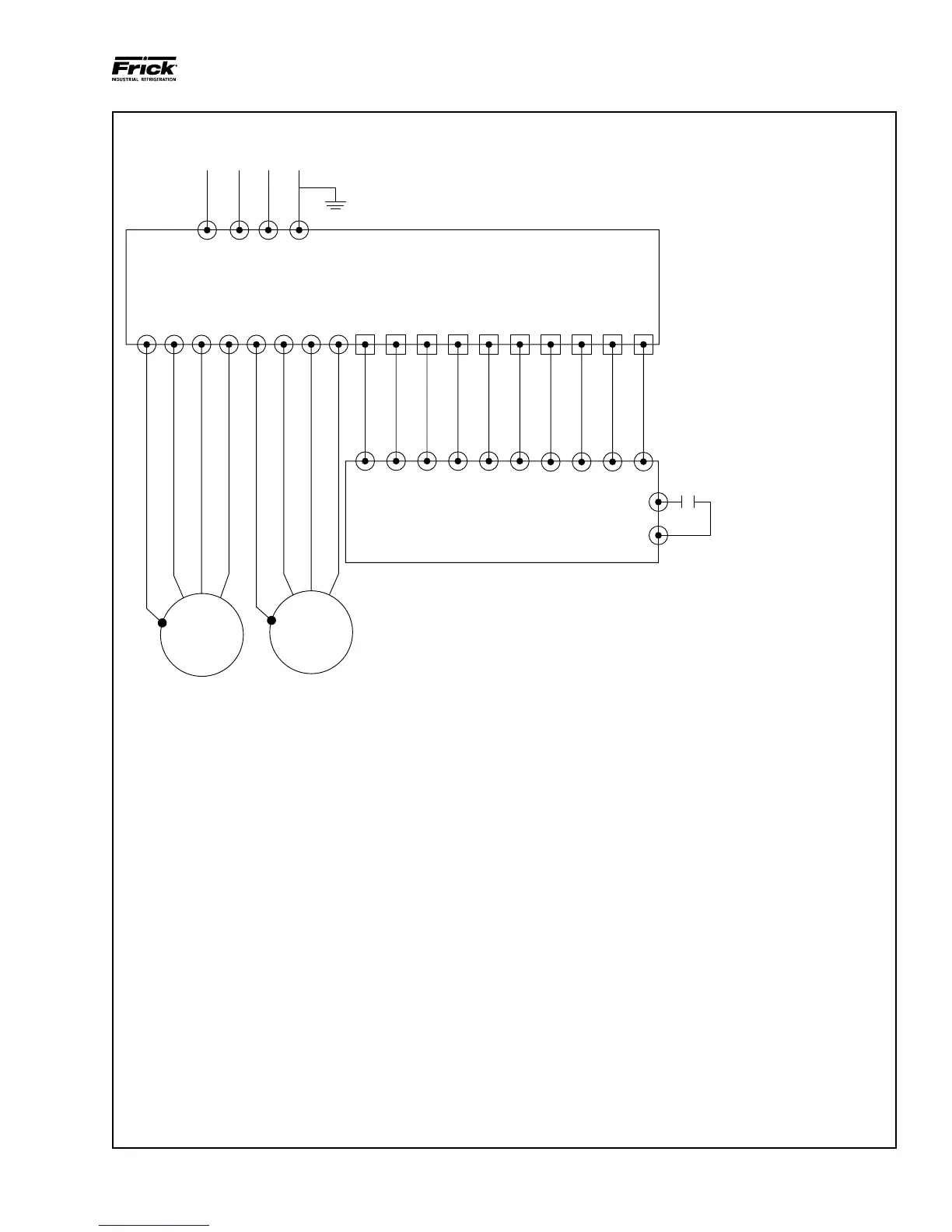

This drawing appears here for reference purposes only, and is subject to change without notice. When installing, or servicing equipment,

always refer to the actual drawings that are included with the control panel for the latest information.

GND T1 T2 T3 GND T1 T2 T3 GND 20 19 18 8 5 4 3 2 1

CONSULT STARTER AND MOTOR WIRNG DIAGRAMS

FOR EXACT WIRING CONFIGURATION

FRICK SUPPLIED COMBINATION

STARTER PACKAGE

Quantum

TM

HD

COMP

MOTOR

OIL PUMP

MOTOR

FRICK QUANTUM

TM

HD ENCLOSURE

5

25

NOTES:

1.

2.

3.

4.

5.

REFER TO MOTOR NAMEPLATE

CORRECT MOTOR CONNECTION.

SEPARATE CONDUIT RUNS

CONTROL VOLTAGE WIRING

MOTOR CONNECTION WIRING.

CONDUIT GROUNDS ARE NO

ACCEPTABLE.

ALL WIRING MUST BE PER LA

EDITION OF THE NEC AND LO

CODES.

ALL CONTROL VOLTAGE WIRING TO

BE 14 AWG STRANDED.

HI-LEVEL CUTOUT

AND/OR OTHER FIELD

SAFETY CUTOUTS AS

REQUIRED.

090.040-WD0052.eps

Figure 36. Point-To-Point Field Wiring Diagram

*(Refer to Frick publication 090.400-SB for installation guidelines)

Loading...

Loading...