QUANTUM

™

HD COMPRESSOR CONTROL PANEL

MAINTENANCE

090.040-M (NOV 2016)

Page 45

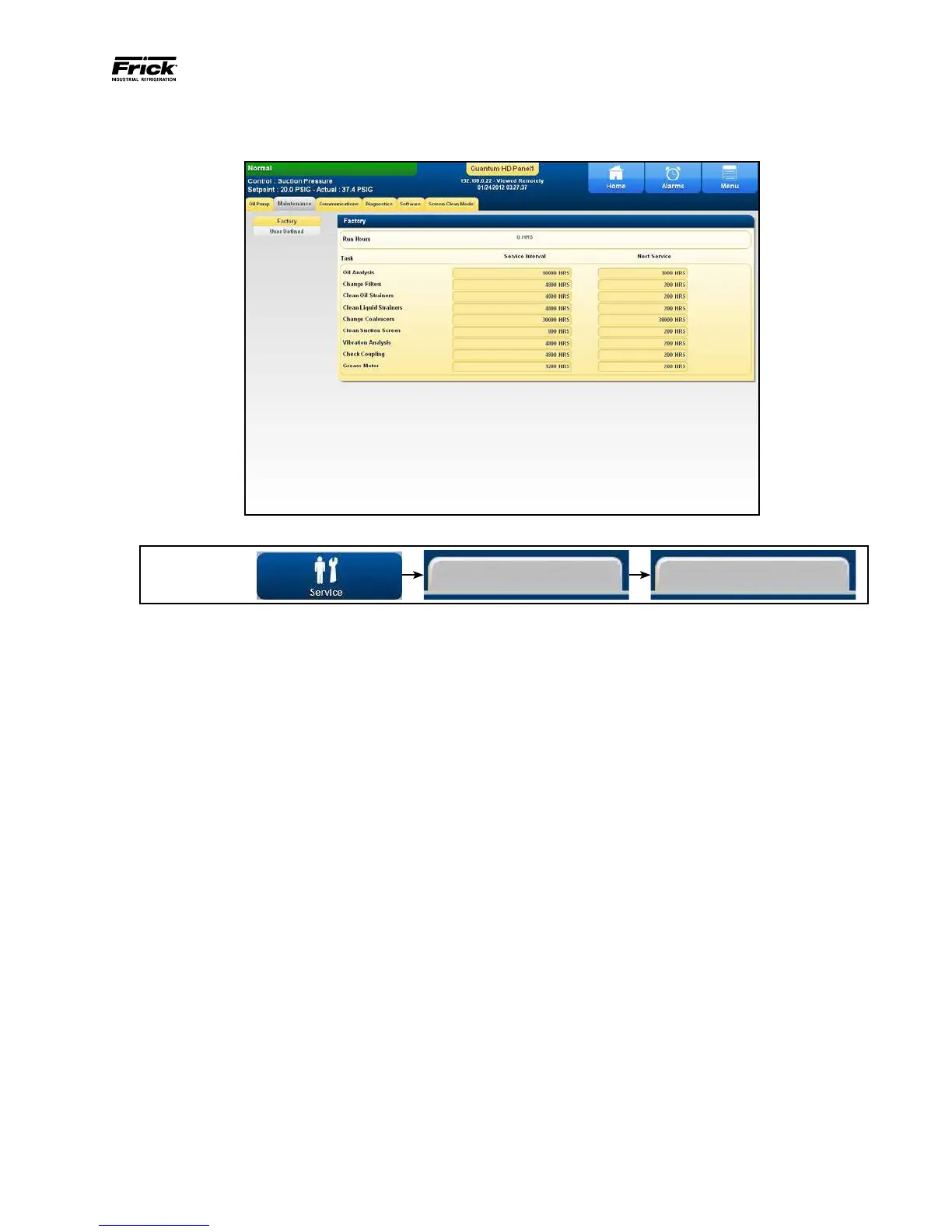

SERVICE - MAINTENANCE (FACTORY)

DESCRIPTION: This screen has been provided to aid the service

technician with keeping track of system maintenance, and can be

accessed from the main Menu. The Tasks will appear on

the Events screen after the Next Service values has been

reached.

The following additional information is provided on this

screen:

Run Hours - The value shown here is the total number of

hours that the compressor motor has actually been in the

running state. This value can be reset (or changed to any

value from 0 to 1,000,000 Hours) from the Conguration >

Package screen.

Task - This column shows a list of nine pre-dened main-

tenance items that may be tracked (an additional 7 custom

items may be tracked on the User Dened screen, see the

next page):

• Oil Analysis

• Change Filters

• Clean Oil Strainers

• Change Coalescers

• Clean Suction Screen

• Vibration Analysis

• Check Coupling

• Grease Motor

Service Interval - This column denes a period of time (in

hours) that will cause messages from the Task column to be

logged into the Event Log. Set this column to the number

of hours between the maintenance check that is dened as

the Task. Once this time has been achieved, a message will

be logged in the Event Log, and the value that is currently

shown in the Next Service column will have the value from

the Service Interval added to it.

Next Service - This column is initially is set to a default value,

which the user may change. Once changed, this value will

become the number of hours that the compressor must run

before the particular Task will be logged into the Event Log.

Once the event has occurred, this value will then be updated

by the value from the Service Interval column.

EXAMPLE: We will use Oil Analysis for instance. When the

compressor is running, the value in the Next Service column

is being clocked. After 1000 hours of compressor run time,

a message will be generated and placed on the Event Log

screen. This particular message will read Oil Analysis, with a

date/time stamp. This message will remain in the Event Log

until cleared. This message is to notify the operator that it

is time to have the Oil checked. At this point, the operator

should notify the proper maintenance personnel that the

appropriate maintenance be performed. The user should

access the Event Screen on a regular basis (perhaps once

per week) to review the information provided there.

Once the message has been entered in the Event Log, the

values for the row will be automatically updated, with new

values as predetermined by an internal programmed main-

tenance schedule. The values for the Next Service column

are based upon the Compressor Run Time hours.

From here, the service technician can view nine mainte-

nance schedules. This screen is based upon the Maintenance

Schedule that is provided in the IOM manual for the specic

compressor package.

ACCESSING:

FactoryMaintenance

090.040-PH0008.tif

Loading...

Loading...