QUANTUM

™

HD COMPRESSOR CONTROL PANEL

MAINTENANCE

090.040-M (NOV 2016)

Page 36

screen. Improper setup of either the hardware or software

will result in improper operation or range.

The most common fault associated with the improper reading

of the analog channels other than hardware or software setup

problems fall into one of the following categories:

• Sensor fault

• Wiring problem

• Improper grounding of system

An open wire, shorted or shunted wire, or faulty sensor will

usually give a reading at either the minimum or maximum

end of the range scale. An erratic reading or a reading that

seems to oat up and down is usually indicative of a ground-

ing problem. When a single transducer or cable is shorted

to earth (or system) ground, this can show up as a whole

assortment of problem channels. The easiest way to nd a

short to earth problem is to disconnect all the sensor plugs

and ohm out each plug screw terminal to earth for open

(innite) impedance. All sensors should read open to earth

with the exception of the CT motor current channel. One side

of the CT is grounded in the Motor Control Center (MCC).

(The third pin on pressure sensors is ground.)

REPLACING A DEFECTIVE ANALOG BOARD

The procedure to replace an Analog board is outlined below:

1. Shut off control power.

2. Unplug all connectors from the board.

3. Remove the old board from the machine and remove the

new board from its packing and place both on an anti-

static surface.

4. Check that all jumpers and dipswitches are properly setup

on the new board as it was on the old board.

5. Install the modied replacement board in the panel.

6. Plug all connectors back in.

7. Turn on control power.

8. After replacing or installing an Analog Board and powering

on the control panel, the processor will start to communi-

cate to the new board automatically. If this does not occur

power down the panel and check the dipswitch settings.

If correct re-power the panel.

If an I/O board is removed for any reason an I/O Comms fail

message for that board will occur. It will be necessary to do

a [Redect I/O Comms] to reset the processor memory as

to which boards it is communicating to. Always check the

about screen after a Redetect to be sure that all boards are

accounted for.

ANALOG OUTPUTS

An Analog Output is the portion of the hardware that the

Quantum™ HD uses to provide control. With the Quantum™

HD, this output is typically a 4-20 mA signal that is output-

ted to an external device. This device is usually a customer

specic application, such as to simply receive a signal back

from the Quantum™ HD providing the Slide Valve Position

to an external application (perhaps a PLC), as an example.

The output can be set as a 0-20mA signal in the calibration

of the output by accessing Menu > Calibration > Output.

The 4-20mA signal can be altered if necessary to a Vdc signal

by using a resistor at the input of the device being controlled.

Refer to the following chart for values:

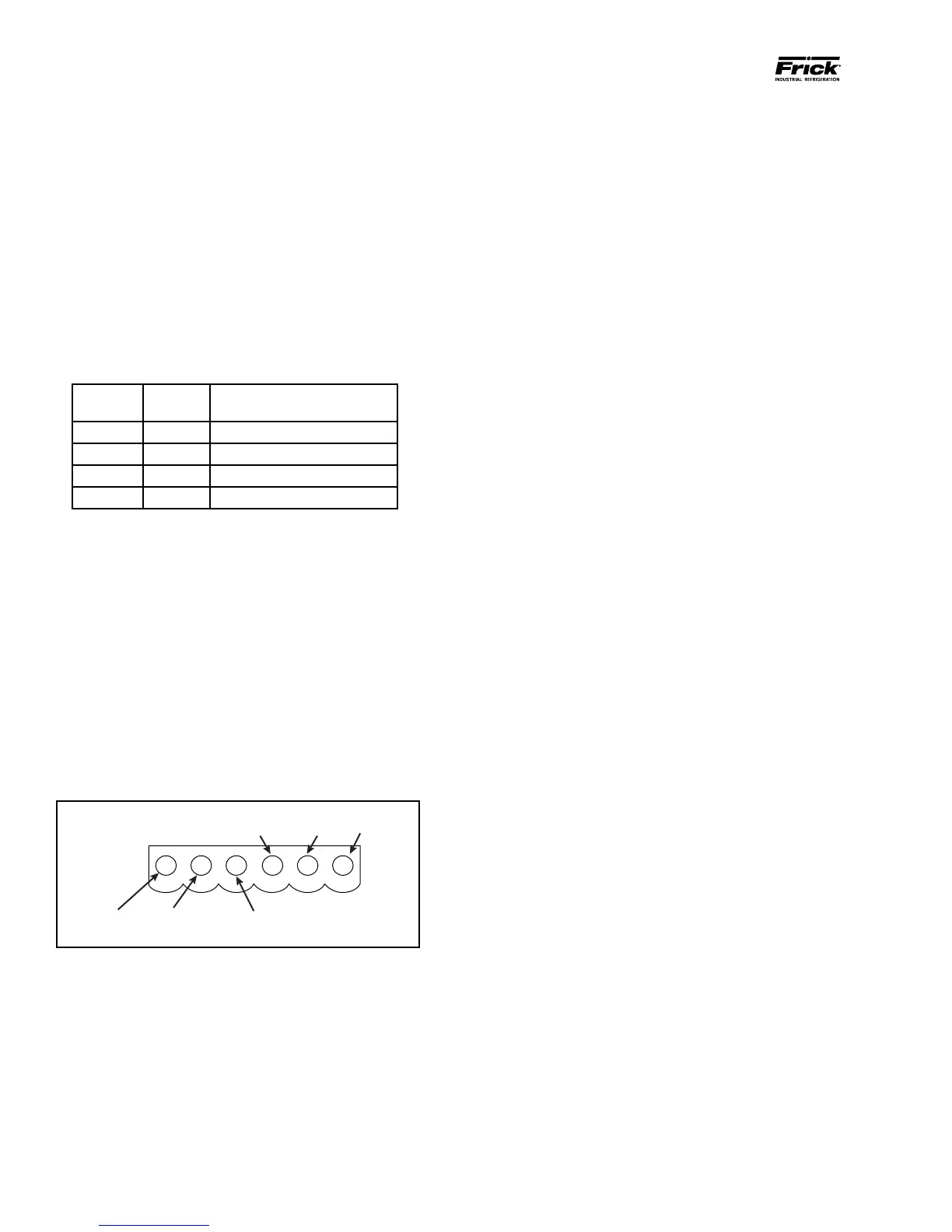

Original

signal

Desired

signal

Resistor to use

4-20mA 1-5Vdc 250 ohm, 1%, 1/4 watt

4-20mA 2-10Vdc 500 ohm, 1%, 1/2 watt

0-20mA 0-5Vdc 250 ohm, 1%, 1/4 watt

0-20mA 0-10Vdc 500 ohm, 1%, 1/2 watt

090.040-TB0011.indd

Table 11. Resistor Values

TROUBLESHOOTING THE

ANALOG INPUTS AND OUTPUTS

Some problems that are encountered involve troubleshoot-

ing the Analog inputs and outputs. The Analog Board has

twelve Analog I/O board connectors labeled P4 through P10.

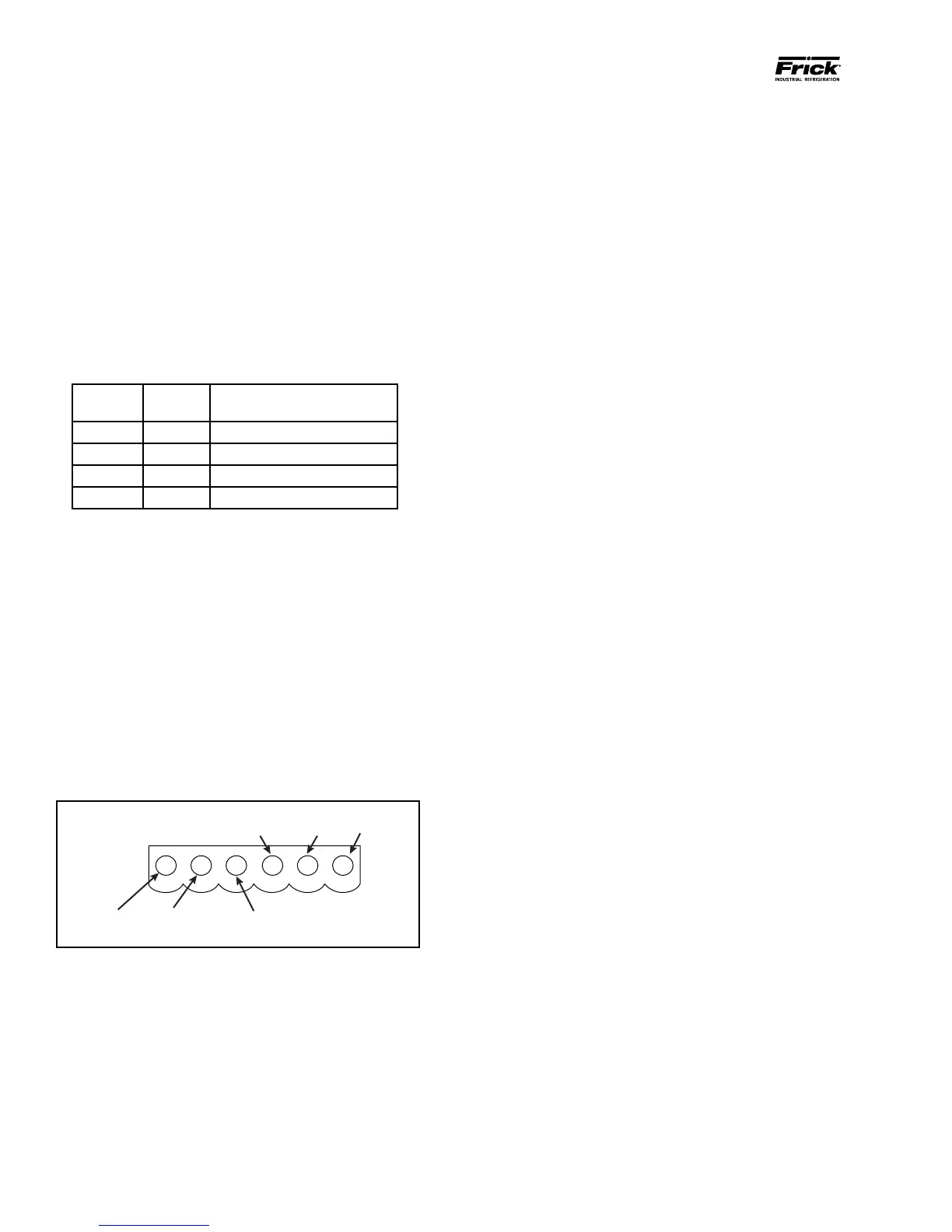

The external Analog devices are wired to a connector plug.

Position 1 connects to the plus (+) of the external device

for channel 1, position 2 connects to the signal (SIG) of the

external device for channel 1 and position 3 connects to

ground (GND) of the external device for channel 1. Position 4

connects to the plus (+) of the external device for channel 2,

position 5 connects to the signal (SIG) of the external device

for channel 2 and position 6 connects to ground (GND) of the

external device for channel 2, as shown below:

Figure 18. Signal Connections

Channel 1

+ Power

Signal

Channel 1

GND

GND

090.040-LD0010.eps

Each channel is setup through software calibration for the

proper transducer type and range, and each transducer must

be calibrated through the appropriate sensor calibration

Loading...

Loading...