Connecting the

welding wire cal-

ibration system

NOTE!

The power cables are not relevant for calibration of the welding wire!

Establish data communication between the following:

▶

power source and calibration system (LocalNet, SpeedNet, USB, etc.)

▶

power source and wirefeeder (LocalNet, SpeedNet, USB, etc.)

▶

welding wire calibration system and calibration system

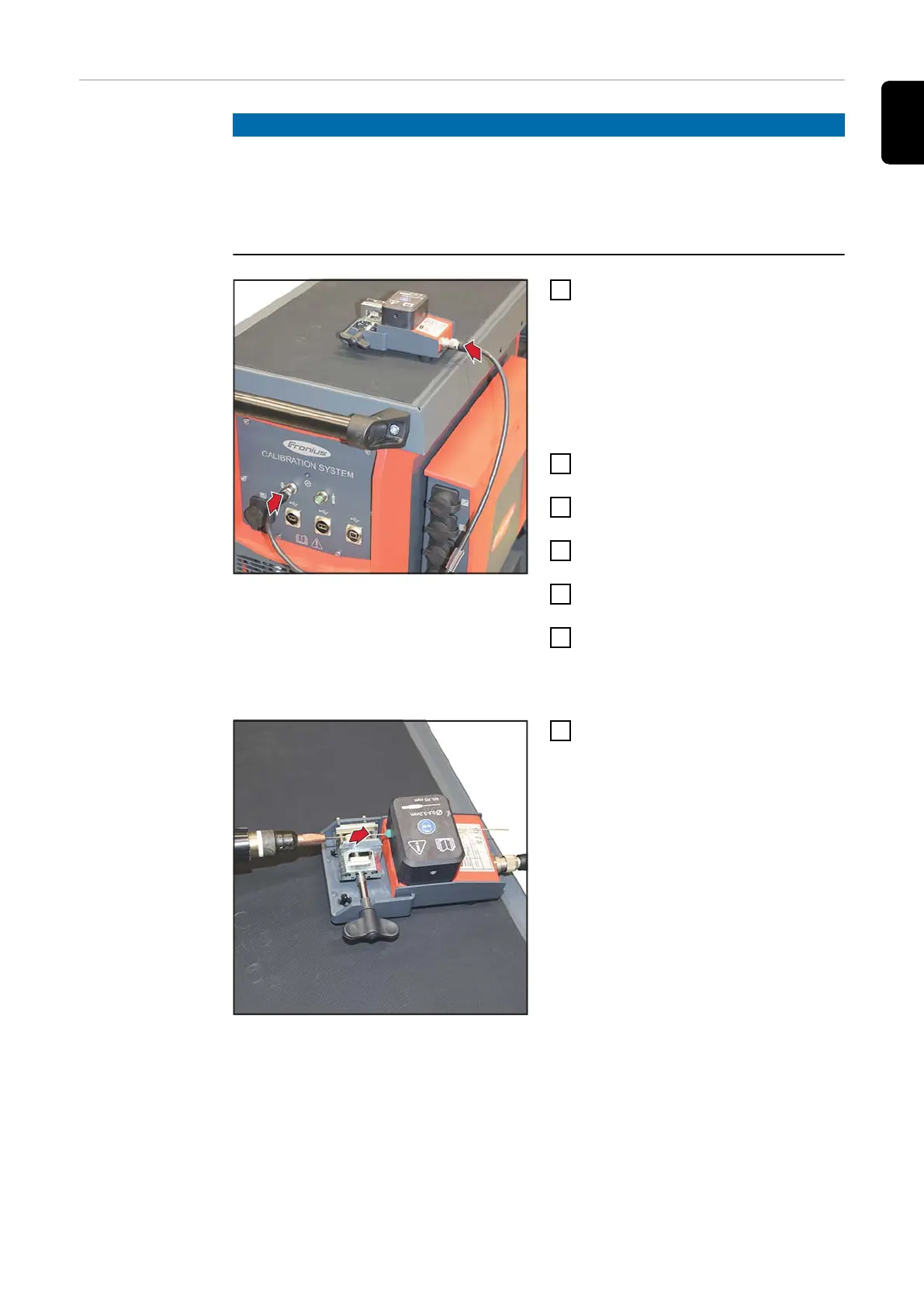

1

Connect the connection cable to

the welding wire calibration system

IMPORTANT! A maximum of 3

connection cables (max. 15 m) can

be used to connect the welding

wire calibration system and the cal-

ibration system!

2

Connect the connection cable to

the calibration system

3

(+) Disconnect power cable from

welding system

4

Connect the welding torch to the

welding system

5

Remove the gas nozzle from the

welding torch

6

Thread the wire

The welding wire should protrude

approx. 200 mm from the contact

tip.

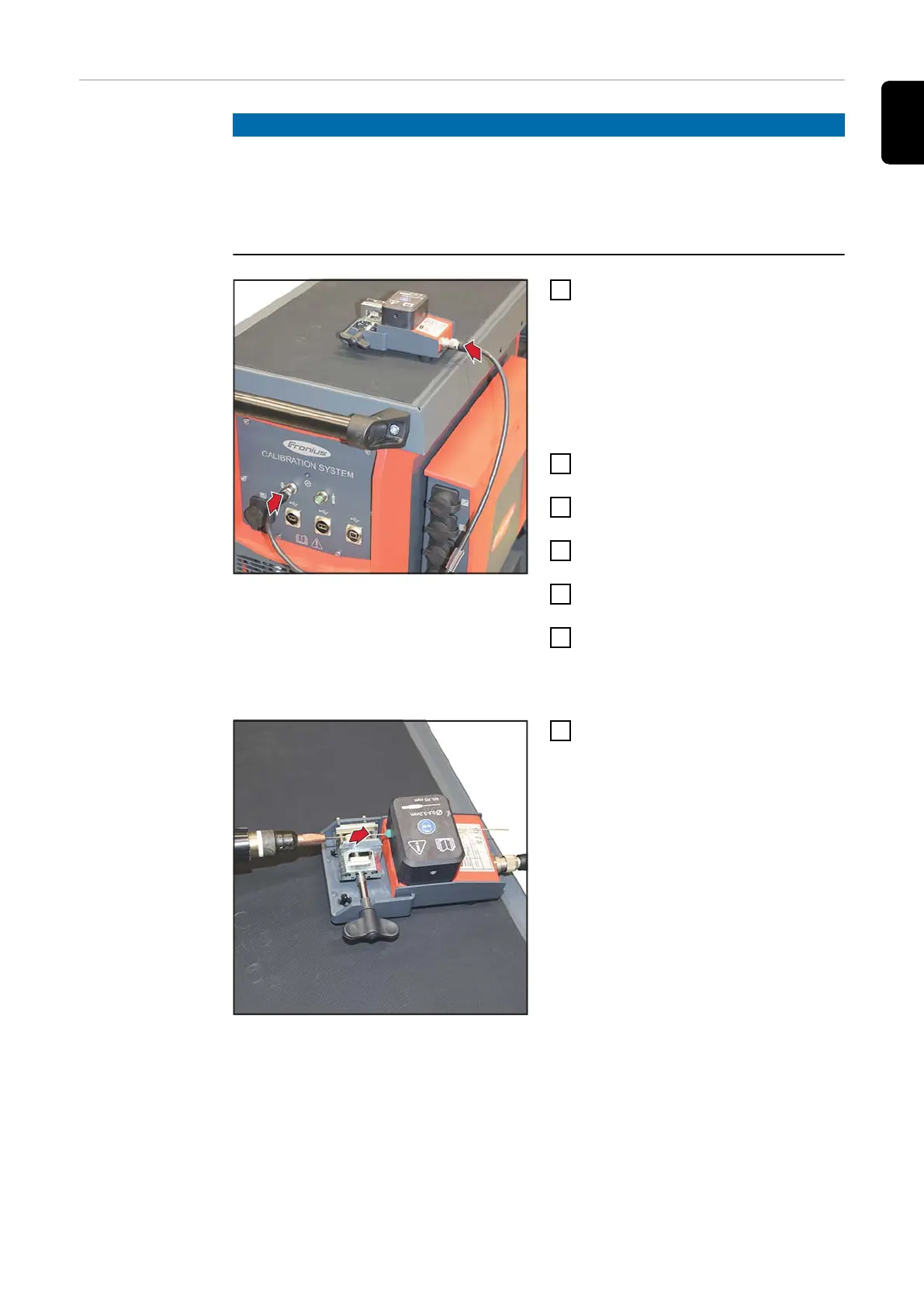

7

Thread the welding wire into the in-

take part of the sensor

45

EN

Loading...

Loading...