© The Fulton Companies 2016

OPERATION VTG-IOM-2016-1214 SECTION 3

3-8

Adjusting Fuel/Air Curve (Multistage #2 Fuel Oil VTG-2000DF to VTG-4000DF)

NOTE: Fulton Vantage boilers are factory test red and pre-programmed with values in the fuel/air curve (P0- ignition to P9-high

re).

With the burner on follow the below steps for making eld changes to the fuel/air curve points. A calibrated ue gas analyzer is

required to complete these steps and must be properly inserted into the boiler ue exhaust vent while making changes to the

fuel/air curve points.

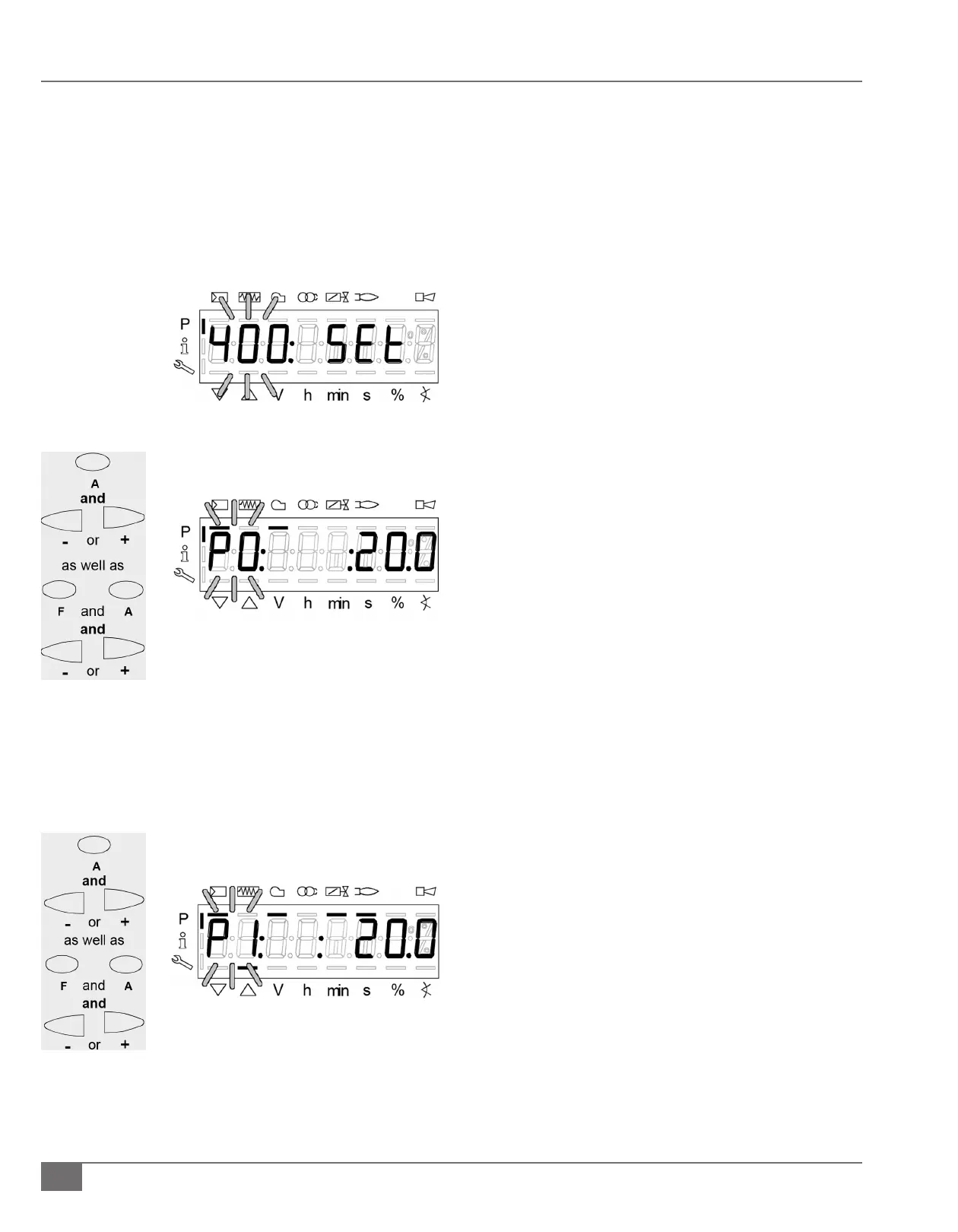

1) Enter the password and parameter “400” will be ashing.

2) Press the enter (i/reset) button 2 times.

a. “P1” will be ashing and the curve point will be

displayed.

NOTE: P0 is the ignition position. Verify proper combustion

at the ignition position.

Oil – Multistage Operation

3) Set/verify oil pump pressure rst - it is the constant.

a. The air actuator is the only actuator adjustable when

ring on oil.

i. There air actuator may be changed as needed at the

following ve positions:

1. P0 – ignition position

2. P1 – stage one, low re position

3. P2on – switch on to stage P2

4. P2d - manual stage P2 air

5. P2 – stage two, high re position

6. P2of – switch o from stage P2

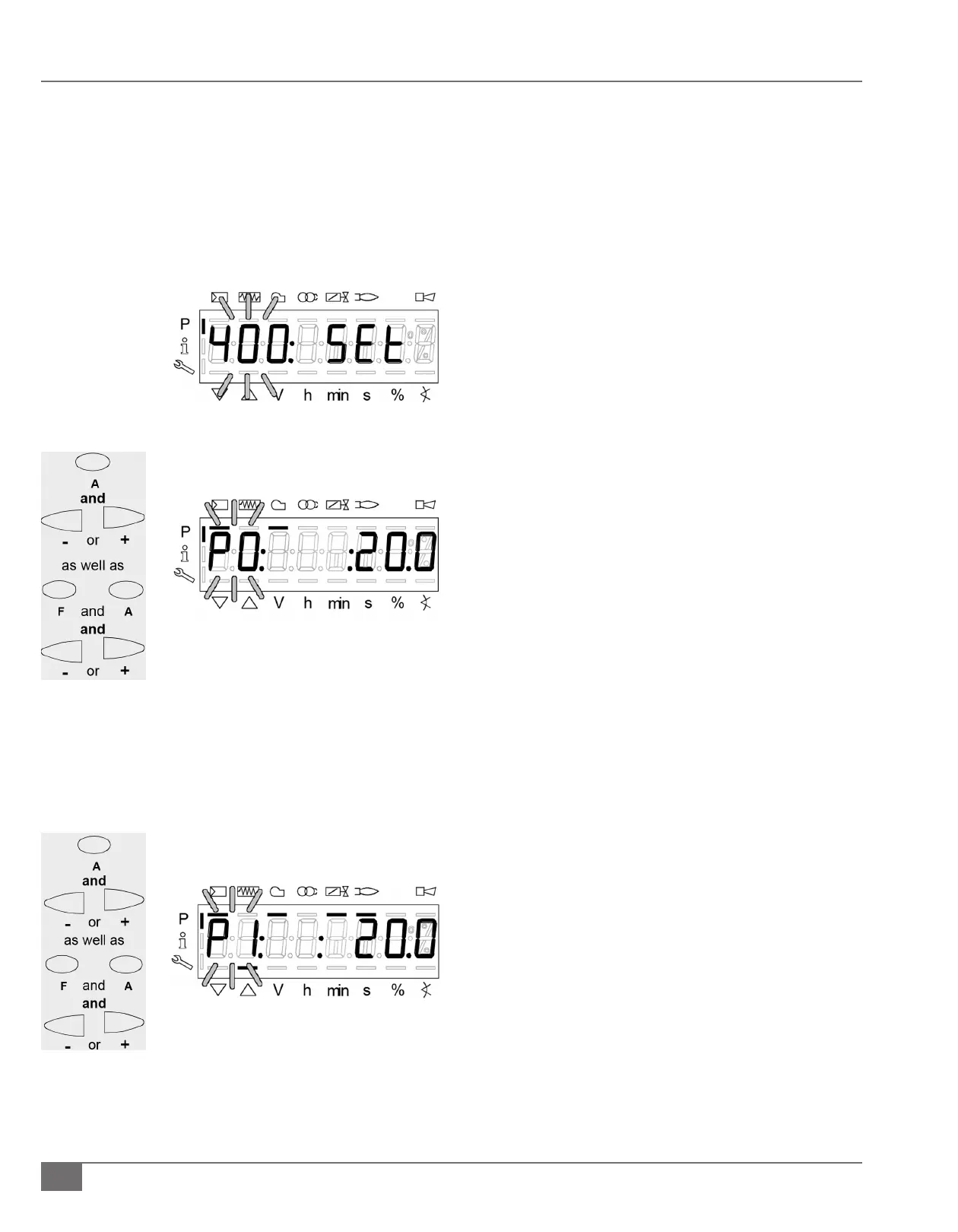

b. For the air actuator keep the “A” button depressed and

the press the “-“ or +” button to adjust the air actuator.

i. Any changes are automatically saved

ii. Release the “A” button

4) Stage “P0” to “P1” press the “+” button to change to the

next stage.

c. “P1” is Stage 1 on, oil owing through one oil

nozzle.

Loading...

Loading...