Questions? Please Contact Your Local Manufacturer’s Representative

SECTION 2 VTG-IOM-2016-1214 INSTALLATION

2-39

4. Pass the vent pipe through the thimble from the

outside and join to the rest of the vent system. Seal the

pipe to the thimble ange with adhesive material.

5. Install two pipe retaining clamps around the intake as

well as vent pipes on both ends of the wall thimble (on

the inside and outside of the wall) through which intake

and vent pipes are passed. They will prevent the intake

and vent pipes from being pushed or pulled.

Roof Vent Termination

Adhere to the following for installation:

1. The minimum vent height should extend at least 3 feet

(0.9 m) above the roof, or at least 2 feet (0.6 m) above

the highest part of any structure within 10 feet of the

vent.

2. When installing inlet and exhaust terminations above

the roof, the exhaust outlet must be installed 4 feet

(1.22 m) minimum above and 4 feet (1.22 m) minimum

downwind from air supply inlet to prevent exhaust

recirculation.

Side Wall Vent Termination

Adhere to the following for installation:

NOTE: The vent termination is joined to the vent pipe outside

the wall. Use the same joining procedures for vent pipe and

ttings.

1. When penetrating a non-combustible wall, the hole

through the wall must be large enough to maintain

the pitch of the vent and provide sealing. Use adhesive

material to seal around the vent on both sides of the

wall. When penetrating a combustible wall, a wall

thimble must be used. Minimum wall thickness through

which vent system may be installed is 3.25 inches (8.26

cm). Maximum wall thickness through which vent

system may be installed is 20 inches (50.8 cm).

2. The termination of the vent system must be at least 12

inches (30.48 cm) above the nished grade, or at least

12 inches (30.48 cm) above normal snow accumulation

level (for applicable geographical areas).

3. The termination of the vent system shall not be located

in trac areas such as walk ways, adjacent buildings,

operable windows and building openings unless the

venting system is at least 7 ft (2.1 m) above nished

grade, (National Fuel Gas Code, ANSI Z223.1).

4. The vent terminations must be at least 4 ft (1.22 m)

horizontally from electric meters, gas meters, regulators,

and relief equipment.

5. When installing inlet and exhaust terminations on the

same wall, the exhaust outlet must be installed 4 feet

(1.22 m) minimum above and 10 feet (3.05 m) minimum

downwind from air supply inlet to prevent exhaust

recirculation.

6. Under certain wind conditions, some building materials

may be aected by ue products expelled in close

proximity to unprotected surfaces. Sealing or shielding

of the exposed surfaces with a corrosion resistant

material (such as an aluminum sheet) may be required

to prevent staining or deterioration. Flue should be

directed away from surfaces, if possible.

Removing an Existing Boiler

When an existing boiler is removed from a common venting

system, the common venting system is likely to be too large

for proper venting of the appliances remaining connected to

it.

At the time of removal of an existing boiler, while the other

appliances remaining connected to the common venting

system are not in operation, the following steps should be

followed with each appliance remaining connected to the

common venting system placed in operation:

1. Seal any unused openings in the common venting

system.

2. Visually inspect the venting system for proper size

and horizontal pitch and determine that there is no

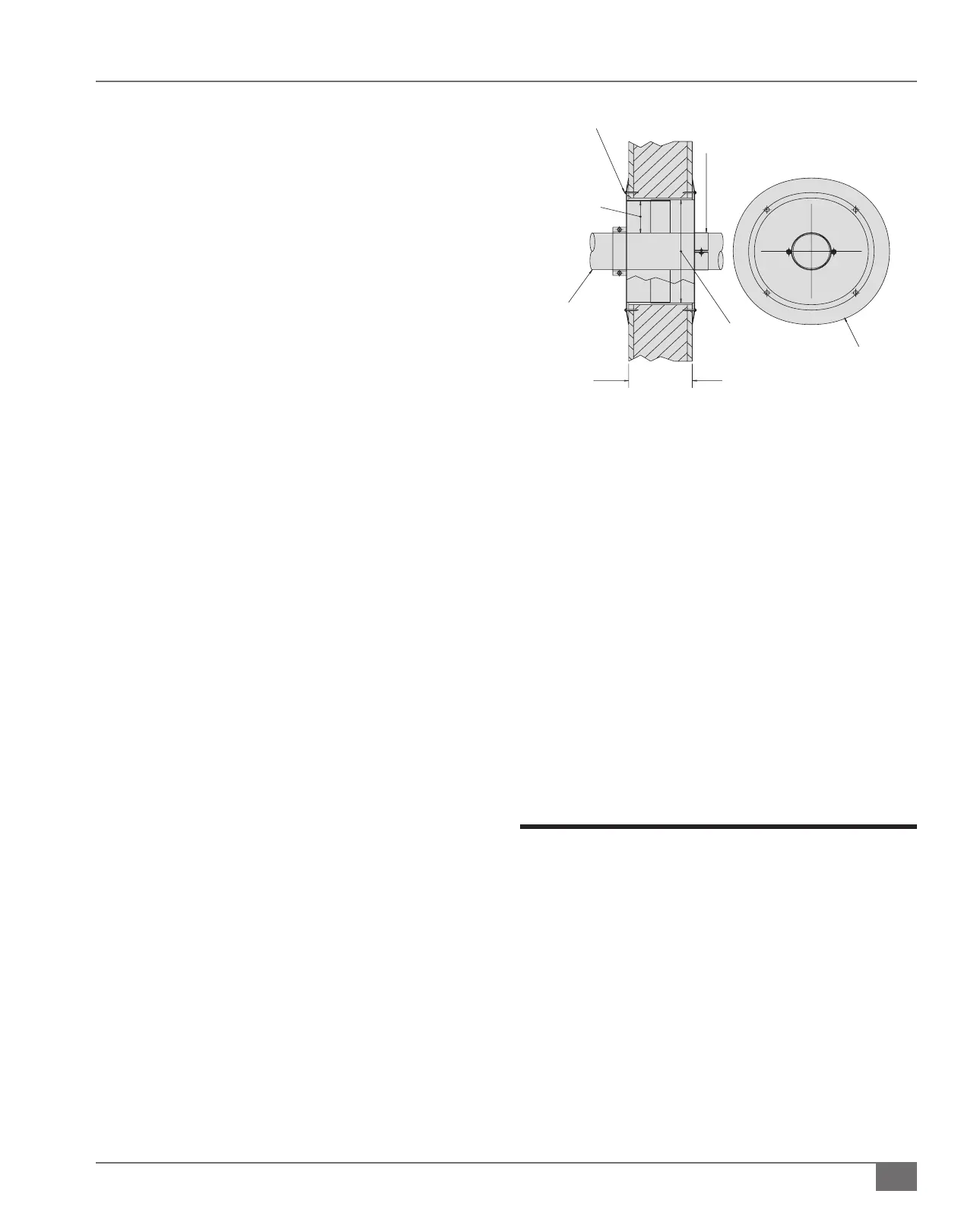

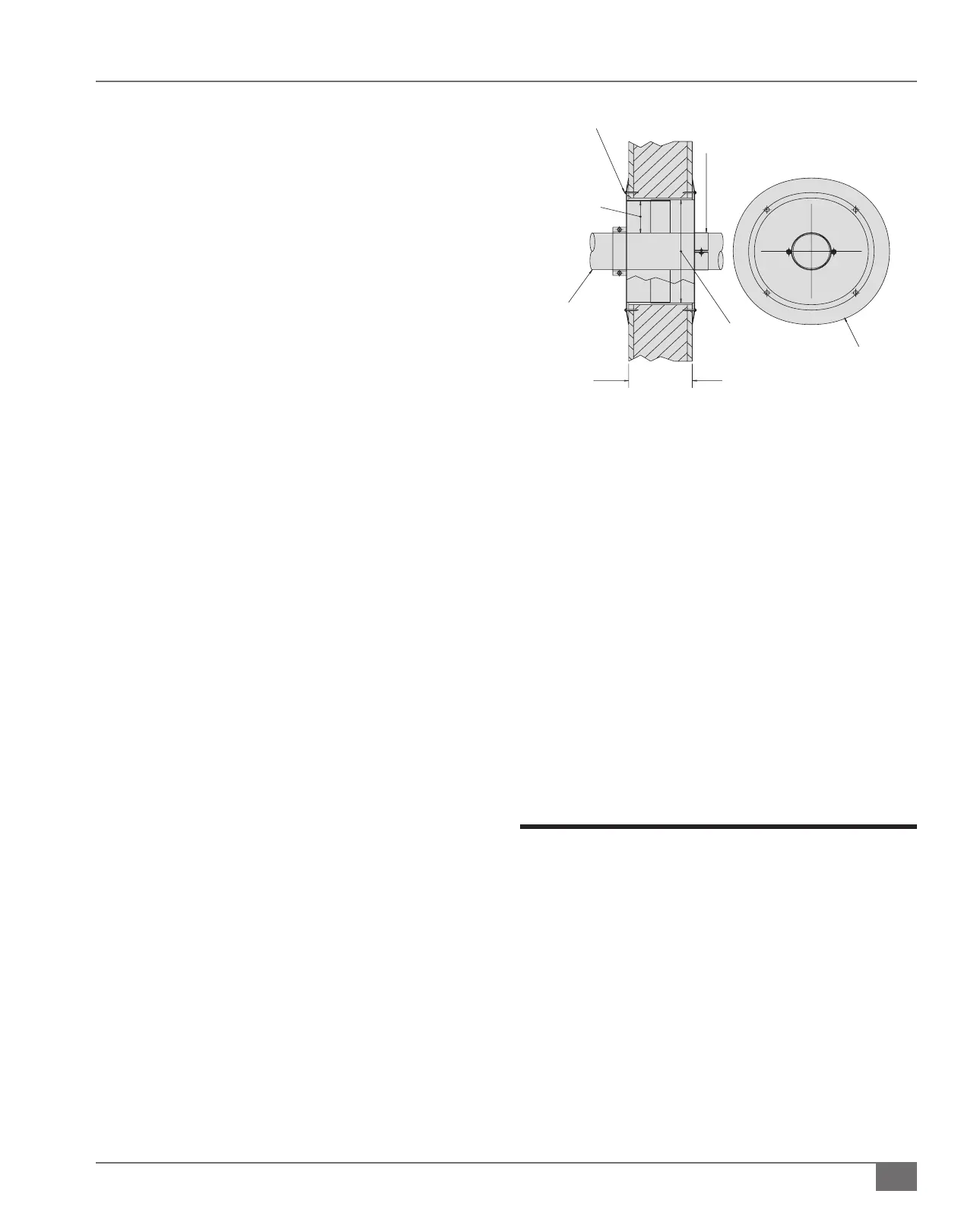

FIGURE 22 WALL THIMBLE INSTALLATION

VARIABLE

(MIN. 3 ¼ IN) – (MAX. 20 INCHES)

(MIN. 8,255 CM – MAX. 50,8 CM)

SCREW OR BOLT EACH THIMBLE COLLAR TO WALL

(TYPICAL 4 PLACES)

ORIENT CLAMPS AND COLLAR AS REQUIRED

PIPE RETAINING

CLAMP, TYPICAL

EACH SIDE

3½ INCH OR

4.35 CM AIR GAP

ALL AROUND

THRU PIPE

DIAMETER “C”

STAINLESS

DIAMETER “B”

ADJUSTABLE

WALL THIMBLE

WIDTH TO VARY WITH

WALL THICKNESS

DIAMETER “A” COLLAR

END VIEW

Loading...

Loading...