Preparation

16 3A6748B

Preparation

Grounding

This product is equipped with a cord having

a grounding wire with an appropriate

grounding plug. The plug must be plugged

into an outlet that is properly installed and

grounded in accordance with all local codes

and ordinances.

Do not modify the plug provided; if it does not

fit the outlet, have the proper outlet installed

by a qualified electrician.

Solvent-Based Materials

NOTE: All hoses sent with the unit are for

water-based material application only.

Solvent compatible hoses and applicators

must be used.

Flush the Equipment

•

Flush before changing materials, before

fluid can dry or cure in the equipment, at

the end of the day, before storing, and

before repairing equipment.

• Flush with a fluid that is compatible with

the fluid being dispensed and the

equipment wetted parts.

• Flush at the lowest pressure possible.

Check connectors for leaks and tighten

as necessary.

1. Follow Pressure Relief Procedure,

page 19.

2. Set pump to lowest possible fluid

pressure, and start pump.

3. Hold a metal part of the gun firmly to a

grounded metal pail. Trigger the gun

until clean solvent dispenses.

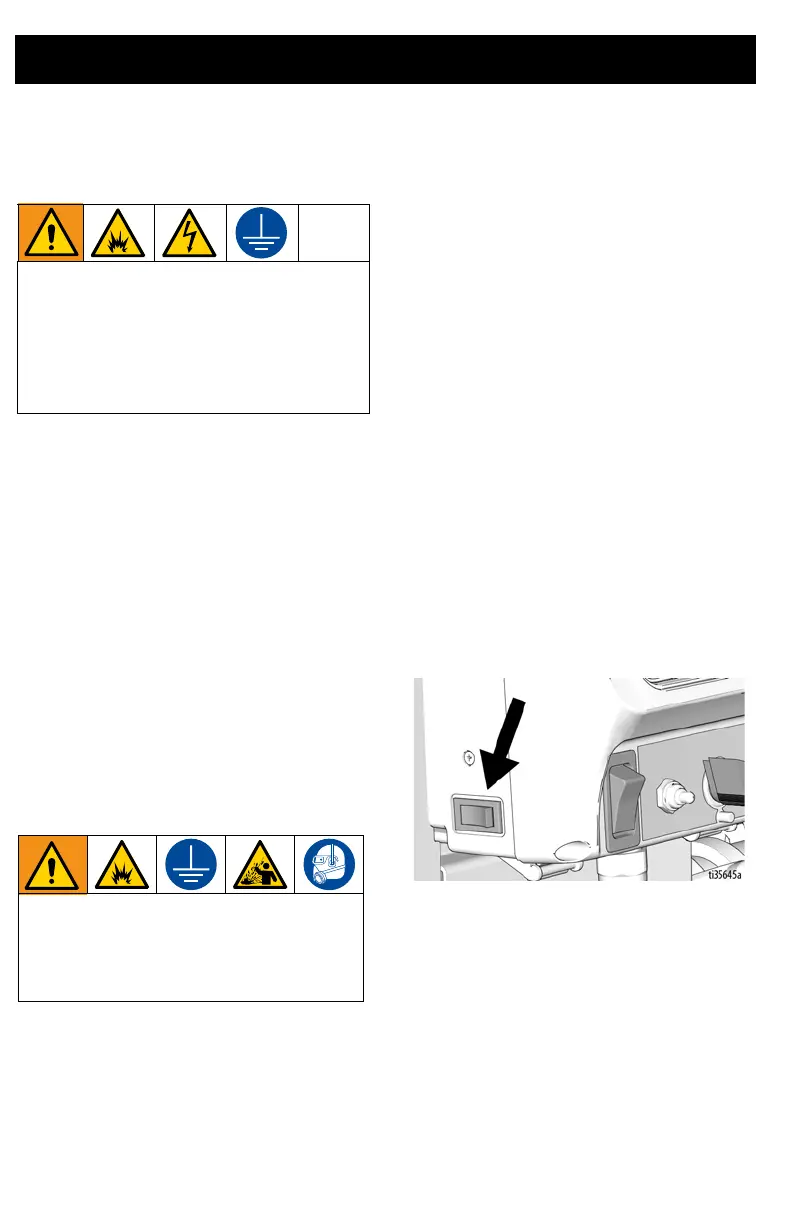

Amp Switch

Select 15A or 20A depending on your circuit

rating. 110V units require 100-120 VAC,

50/60 Hz, 15 – 20A, 1 phase

Select 10A or 16A depending on your circuit

rating. 230V units require 220-240 VAC,

50/60 Hz, 10 – 16A, 1 phase

The equipment must be grounded to

reduce the risk of static sparking and

electric shock. An electric or static spark

can cause fumes to ignite or explode. An

improper ground can cause electric shock.

A good ground provides an escape wire for

the electric current.

To avoid fire and explosion, always

ground equipment and waste container.

To avoid static sparking and injury from

splashing, always flush at the lowest

possible pressure.

Loading...

Loading...