Start Up - Air Assist

28 3A6748B

Start Up - Air Assist

Perform the start up procedure each time the

sprayer is started for the first time after it has

been cleaned or stored.

1. Perform Pressure Relief Procedure,

page 19.

2. To help prevent packout, fill material

hopper with hose lubrication. See Hose

Lubrication Mixing Instructions, page

18, then follow prime instructions. Pump

all hose lube through hose back into a

bucket then continue with the material

prime.

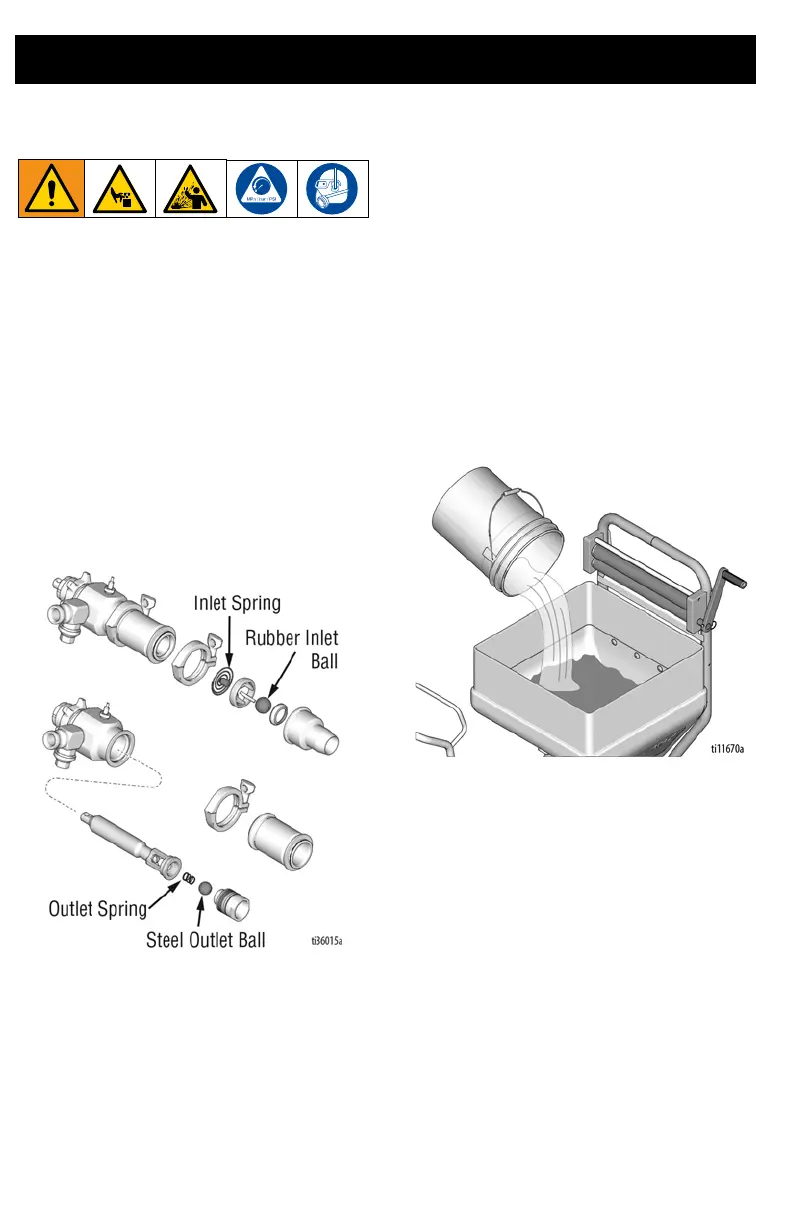

If spraying large aggregates, use rubber inlet

ball with spring and steel outlet ball with

spring.

NOTE: If having packout issues in the pump,

remove the outlet spring and run without it.

To prime without outlet spring, remove hose

and pour water into the outlet. Place unit in

“flow mode” and turn Pressure Control Knob

clockwise until material comes out of the

pump outlet. Turn pressure control

counterclockwise until flow stops, then

connect material hose. If applicable, connect

a prime valve to the outlet, then connect

material hose. Open prime valve and slowly

turn the pressure control knob clockwise until

material comes out the prime valve.

Close prime valve and allow the hose to fill

(prime valve sold separately).

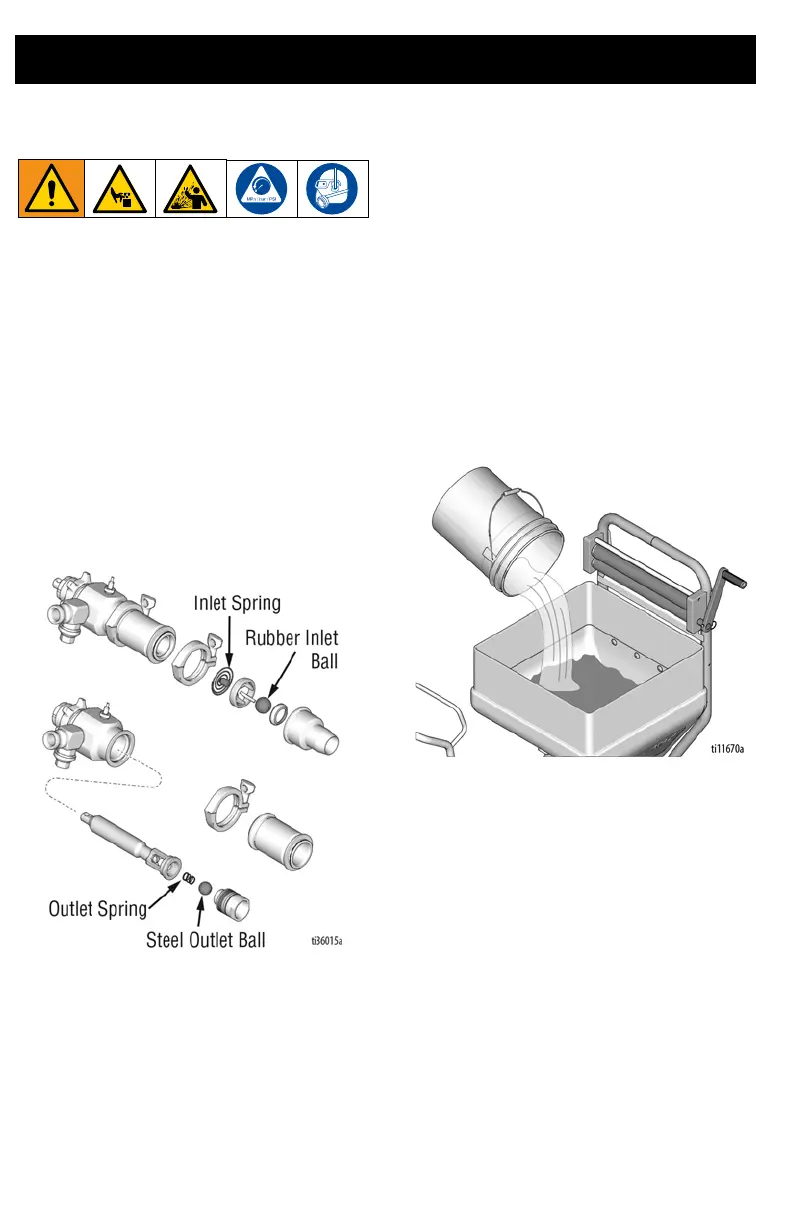

3. Fill hopper with mixed texture material.

NOTE: While priming material, allow residual

hose lube to flow into a bucket until material

starts to comes out.

Loading...

Loading...