73

M_M20 series V3_EN_C

Preventive maintenance

Adjustment: Automatic ZRef

1. Switch on the machine.

2. Use the spindle with a nose, without a cutter and without pressure (Position 1) or use the spindle

with the diamond tip.

M20 PIX: Use the spindle with the diamond tip.

3. Position a plate in the vice.

4. Presssimultaneouslyonthe2keys:Pause-ZRef.

The tool holder moves to the center of the vice. The spindle moves down until the tool touches the plate.

5. SetthezeropointintheZaxisofthemachineusingthefollowingkeys:Up-Downarrows.The

point must come into contact with the surface to be marked.

6. StorethepositionoftheZzeropointby pressingthe"Check"key for3seconds.The machine

emits an audible signal.

Adjustment:JEWELkit(ringengraving)

The machine needs to be adjusted after the diamond tip has been changed or after any change to the

electronics.

Adjust these settings every 3 months or whenever the machine has been moved.

• Adjusting the machine in X-Y:

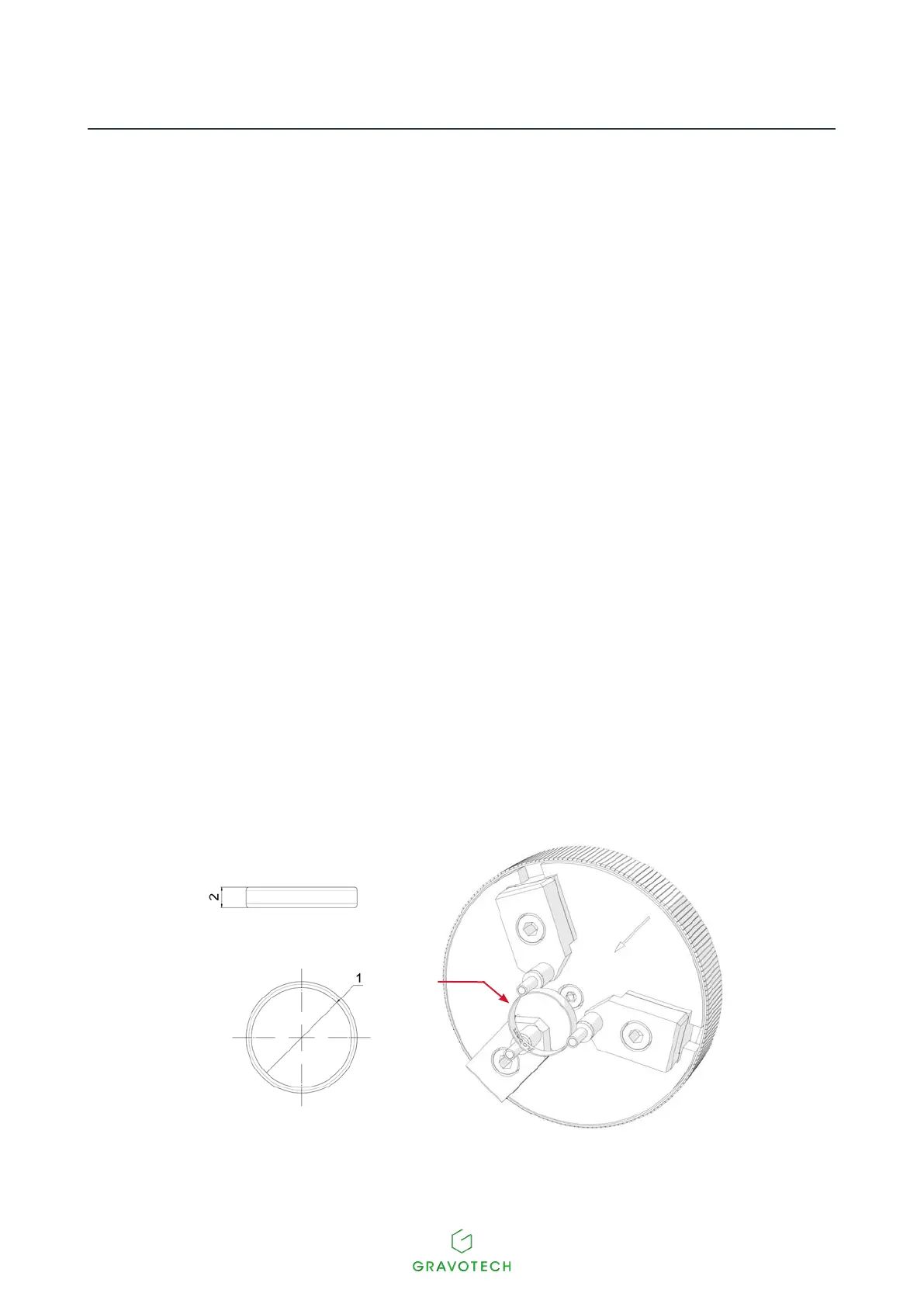

1. Place a reference ring in position on the chuck according to the desired marking (Exterior or

Interior).

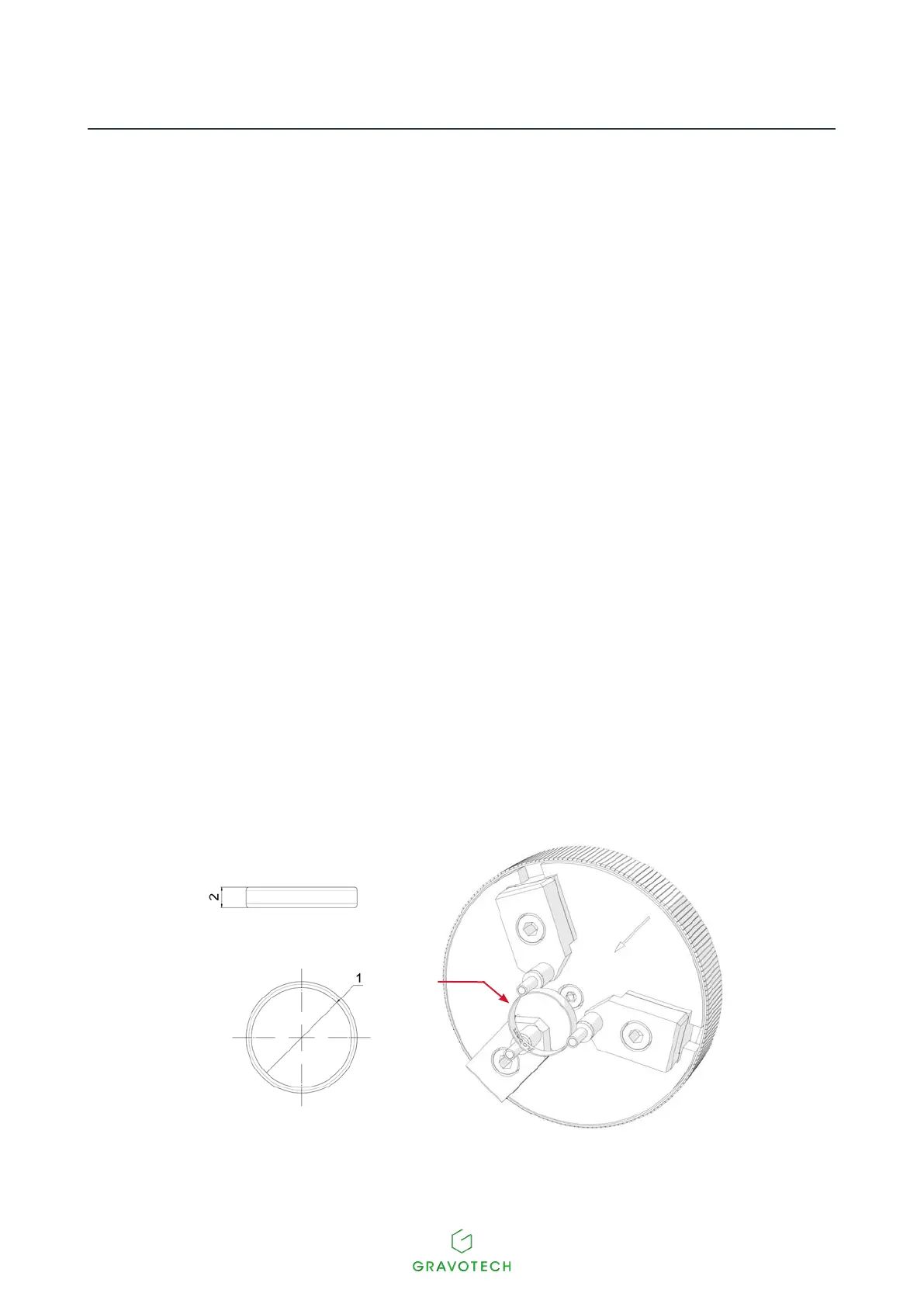

Inside engraving

3

1.

Internal diameter

2.

Width

3.

Reference ring(s)

Loading...

Loading...