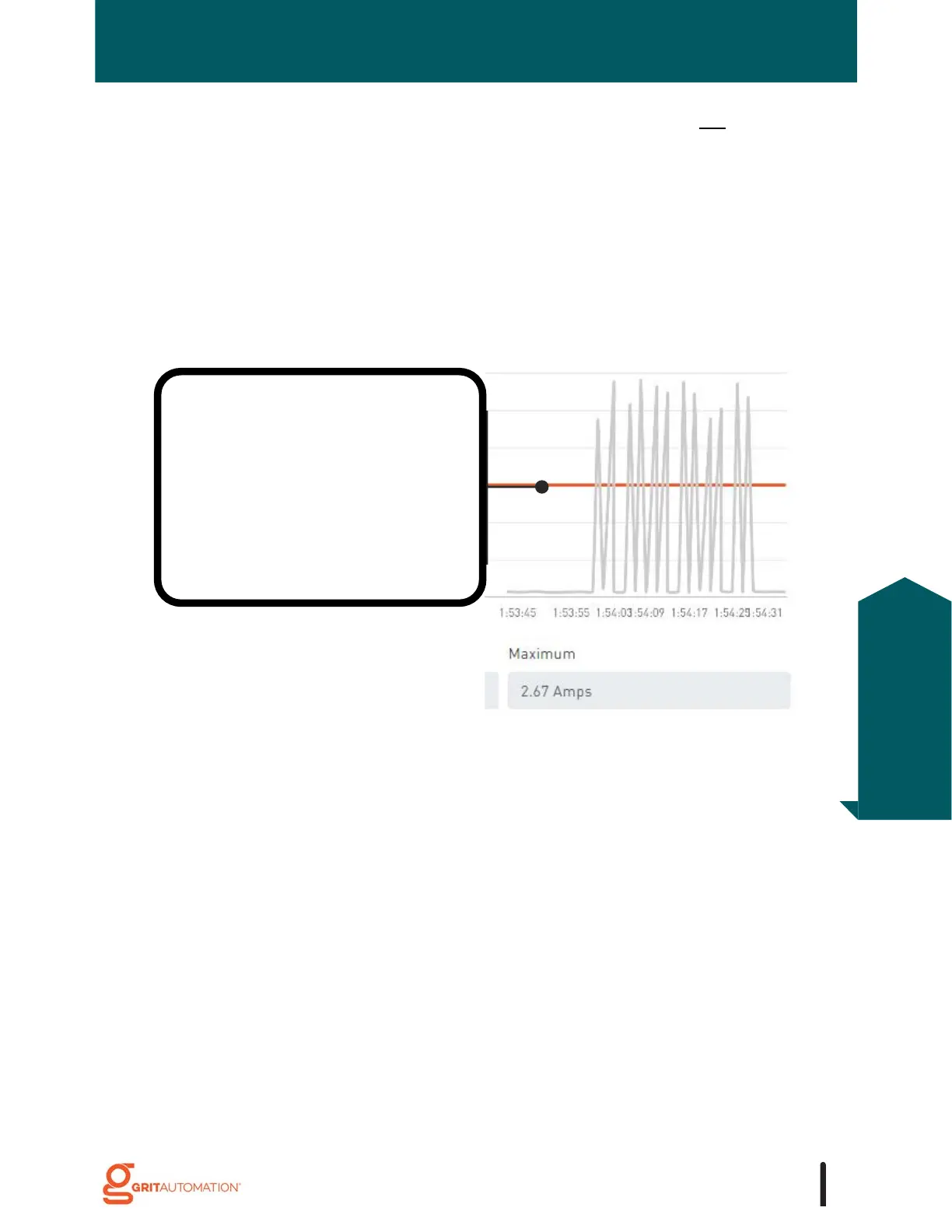

2. The Deactivation Delay setting controls how long the trigger needs to not sense the

current flowing before the attached tool is considered off. This setting is used when a tool

might cause repeated on/off current spikes (e.i., CNC or laser). The desired functionality is

that these quick power spikes should not be viewed as lots of on/off commands, but

instead wait for the current to stop flowing for the length of time specified in this setting

before considering the tool to be off.

3. The Unlock Measurement Delay* setting controls how long the trigger will wait between

unlocking and measuring the current from the attached tool. For instance, some tools

have a soft start that require this value be set above zero. If you find that GRIT is not

correctly sensing a tool that was left in the ON position when the trigger is unlocked, this

value needs to be adjusted higher. The higher the value, the longer GRIT will wait before

checking for current flow.

*Be aware, the downside of this setting is that if it is set too high, it will allow a tool to

unintentionally run longer than it would need to during an Emergency Lock situation.

TRIGGERS

Example: A power graph of a

laser would show the need for a

Deactivation Delay setting set

above 0 sec. so that the system

does not think the machine is no

longer running each time the

laser stops firing.

61

Triggers

Configuration

Loading...

Loading...