Adjustments and tool changes

Operational readiness when using grooving tools

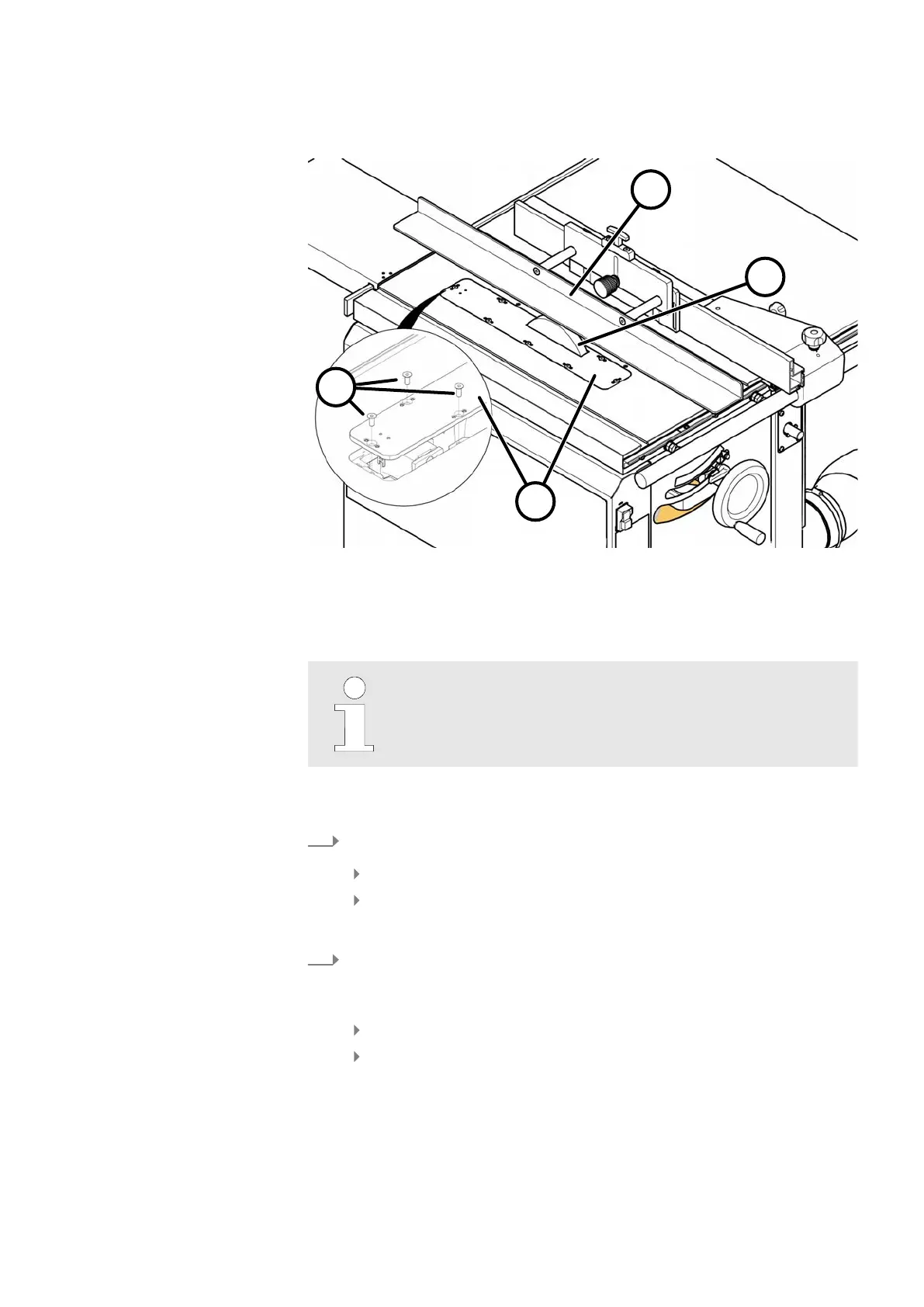

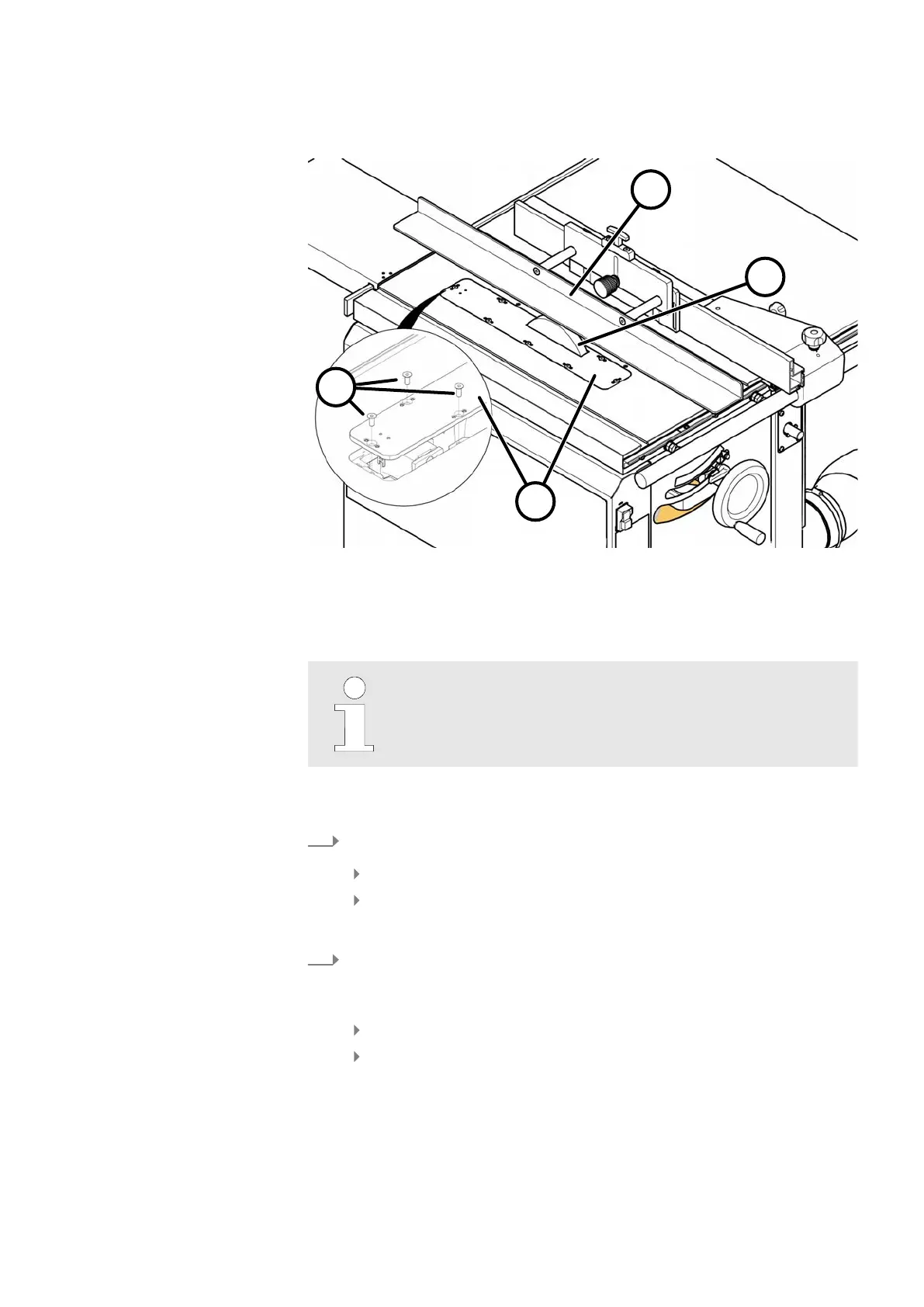

Fig. 9: Operational readiness - grooving tool

1 Insert board (Art.-no. 500-07-206)

2 Flat head screws M6x16

3 Tenoning hood "Sägeboy"

4 Grooving tool

Operational readiness

T

he saw blade only operates if the limit switch inside the machine

frame has not been actuated by the locking system.

Tool:

● Allen key 4 mm

1.

Inserting the insert board.

Position the insert board in the machine table from above.

Screw in 7 countersunk screws with an Allen key.

🡆

The insert board must sit flush with the machine table.

2.

Mount the tenoning hood and "Sägeboy" auxiliary fence to the rip fence.

⮫

Chapter 1.1.4 ‘Mounting the "Sägeboy" auxiliary fence to the rip fence’

on page 7

Clamp the Sägeboy to the rip fence with thumb screws.

Adjust the rip fence so that the tool is covered by the Sägeboy guide

r

ail.

🡆

Assembly, operation and adjustment: See own operating instructions.

Loading...

Loading...