3.

Adjust the rip fence so that the edge of the saw blade is flush with the

Säg

eboy guide rail.

🡆

The Sägeboy guide rail also serves as a fence for sawing with templates.

4.

On machines with sliding table:

L

ock the sliding table into the centre position.

If an eccentric clamp is used, mill out the groove using the sliding table.

5.

Always use the crosscut fence when making transverse grooves. ⮫

Chapter

2.3.7 ‘Crosscutting with the crosscut and rip fence’ on page 31

6.

When feeding the workpiece forward, press it hard onto the machine or

slidin

g table.

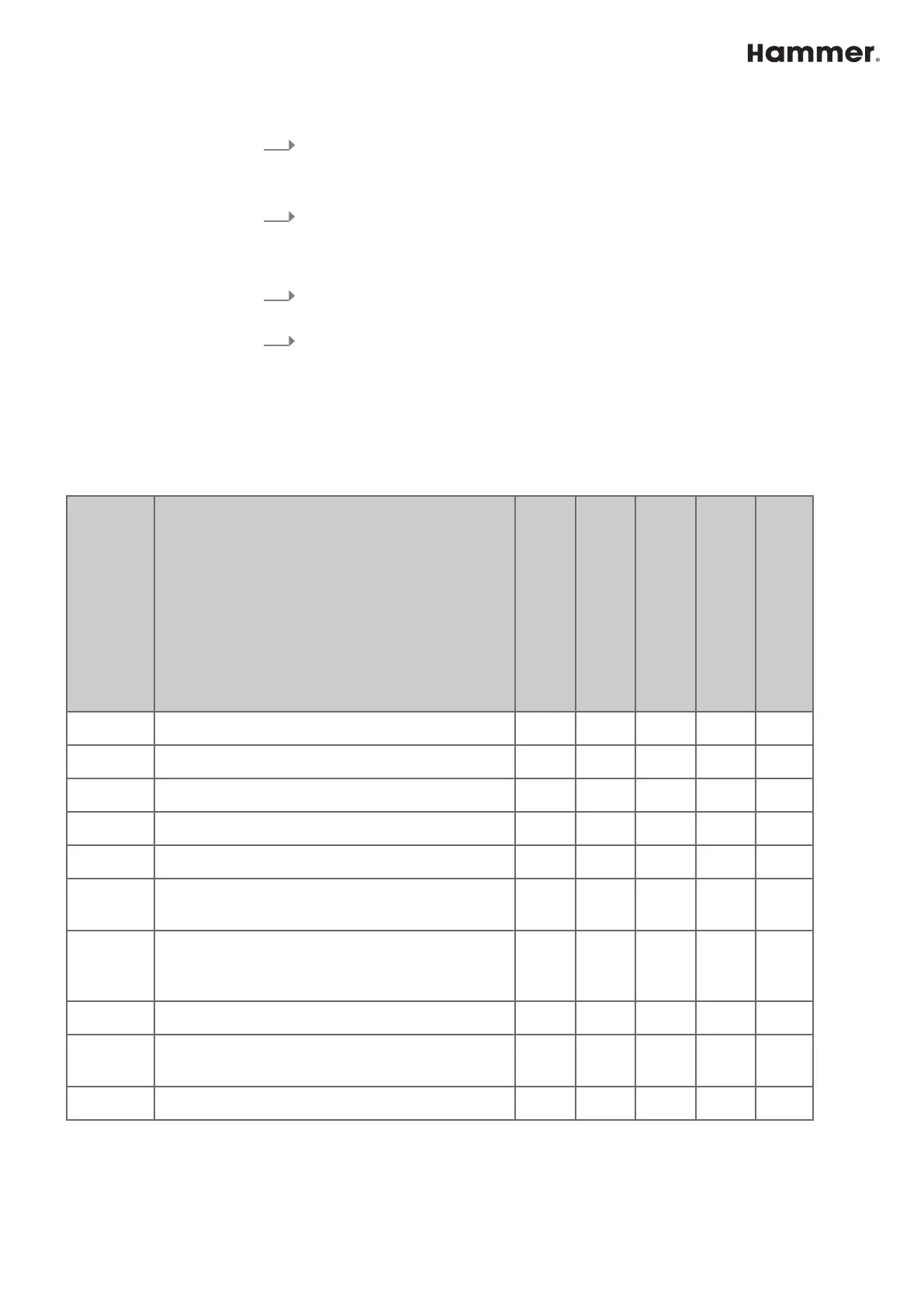

3 Maintenance

3.1 Maintenance schedule

The following maintenance work must be performed at the prescribed intervals.

Chap. Task to execute

Every 160 operating hours

3.4.1 Clean the machine thoroughly X 36

3.4.3 Lubricate the height guide of the circular saw unit X 37

3.4.4 Check dust extractor for any damage X 38

3.4.4 Check the effectiveness of the dust extractor X 38

3.4.5 Check safety devices (emergency stop) X 38

3.4.5 If the machine is equipped with an [emer

gency

stop] button, test the functionality

X 38

3.4.5 Check the red [stop] button and the emer-

gency stop on machines not equipped with an

[emergency stop] button

X 39

3.4.6 Check effectiveness of safety devices (end switch) X 40

3.4.7 Lubricating the circular saw height spindle and

t

ilting spindle

X 41

3.5.1 Check belt tension and belt condition X 42

Loading...

Loading...