4.

Press the green [S

tart]-button on the control panel.

🡆

The machine will not switch on (insert board removed).

5.

The saw blade only operates if the limit switch inside the machine frame has

no

t been actuated (insert board must be inserted).

3.4.7 Lubricating the circular saw height spindle and tilting spindle

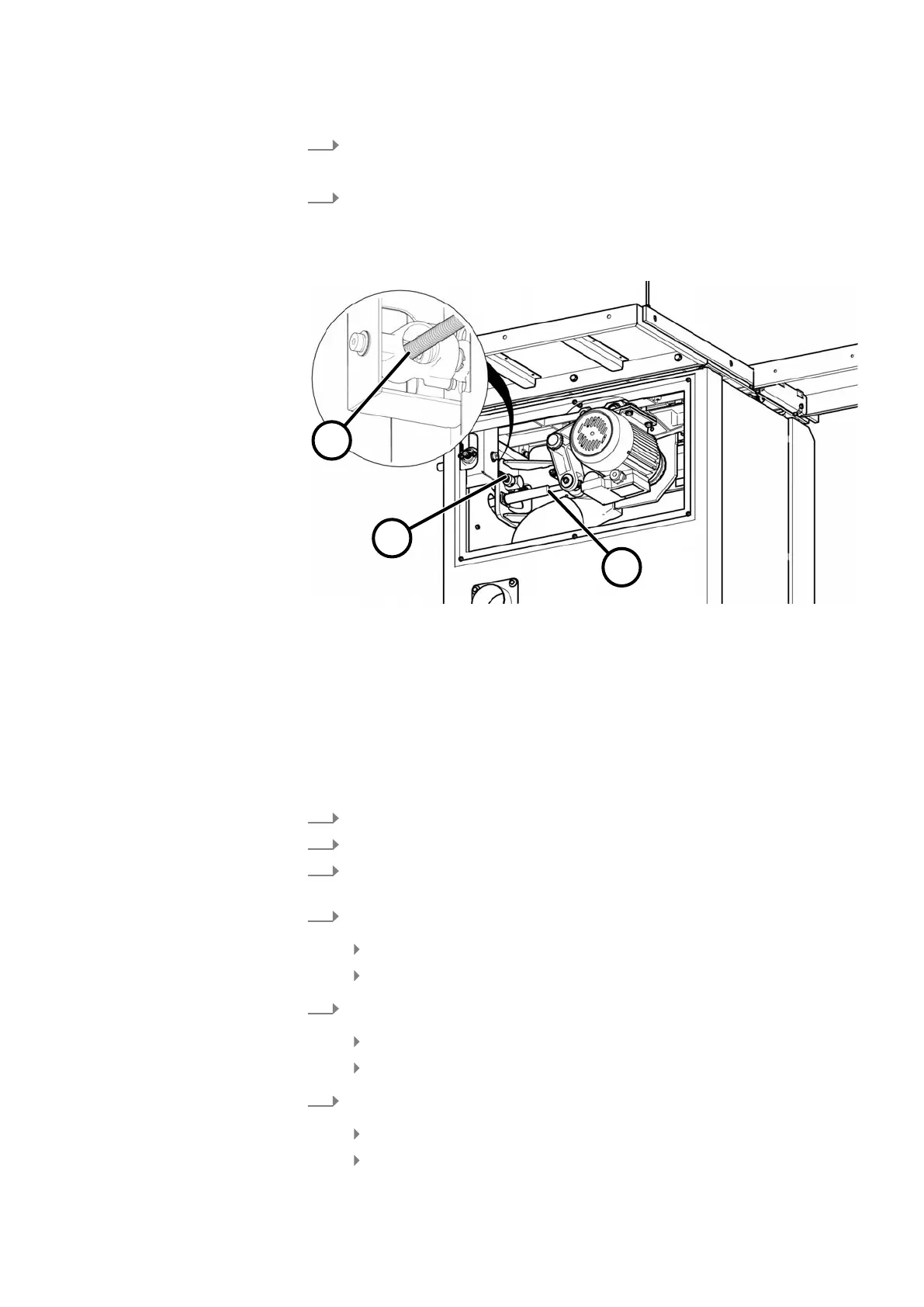

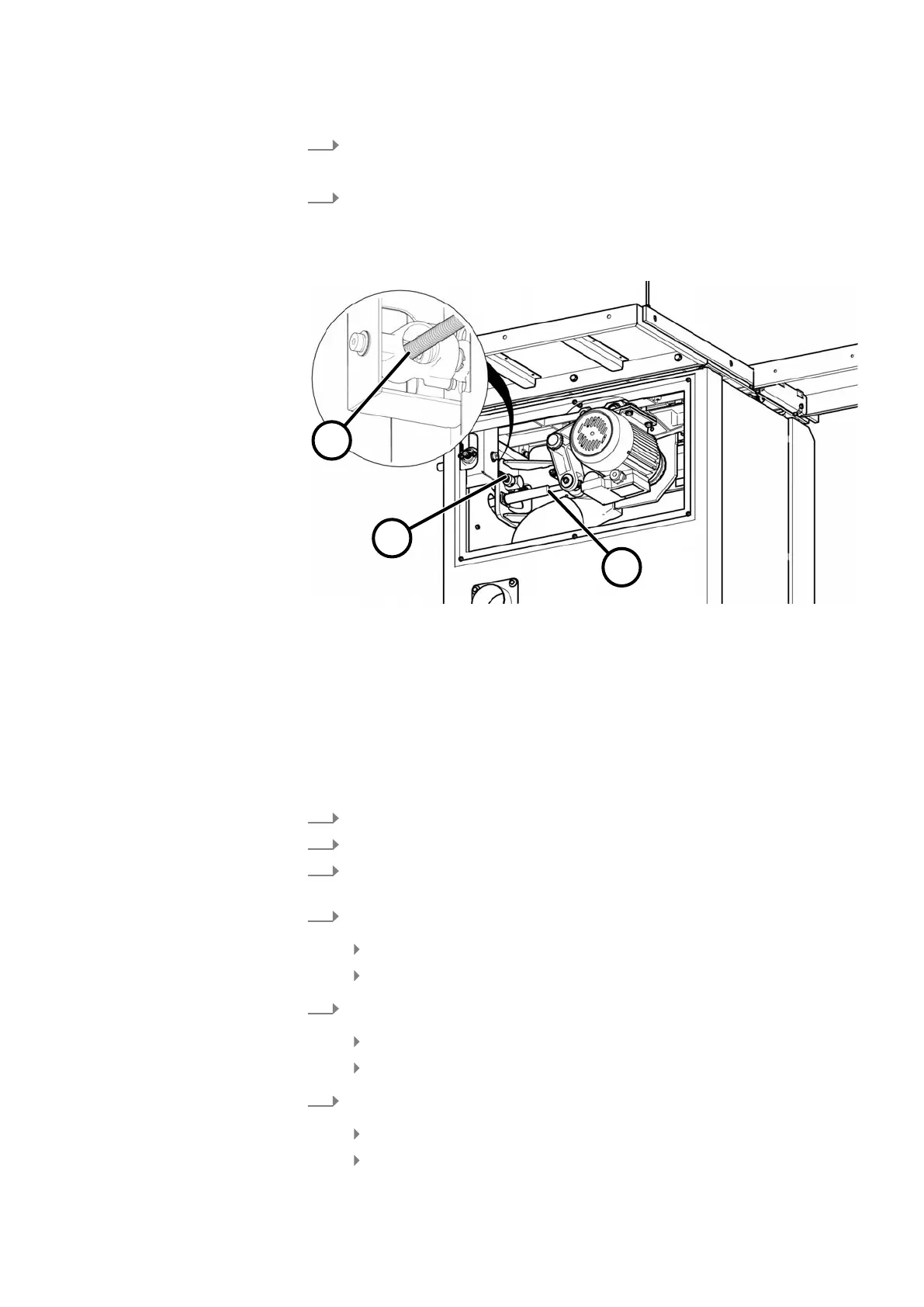

Fig. 33: Lubricate adjustment spindle

1 Tilting spindle

2 Height spindle

3 Bevel gearbox (angle adjustment)

Tool:

● Grease gun

Ma

terial:

● Machine Grease

1.

Switch off the machine and secure it against being switched on again.

2.

Disconnect the machine from the mains power supply.

3.

Remove the rear cover plate. ⮫Chapter 3.2 ‘Preparations for maintenance

work / Removing the cover plate’ on page 35

4.

Lubricating the height spindle:

Position the saw aggregate in the uppermost position.

Lubricate height spindle with normal machine grease.

5.

Lubricating the tilting spindle:

Tilt the saw aggregate in the 90° position (cutting angle 0°).

Lubricate the swivel spindle with normal machine grease.

6.

Lubricating the bevel gearbox:

Insert the flexible hose of a grease gun into the gearbox housing.

Lubricate the gearbox with a press stroke.

Loading...

Loading...