Adjustments and tool changes

7.

Secure the saw arbour against rotation.

Insert the locking pin into the hole on the circular saw table.

Turn the circular saw shaft until the locking pin engages.

8.

WARNING F

lying pieces

Severe injuries and damage to property.

● Minimum tightening torque of the clamping bolt: 20 Nm.

Tighten the clamping screw with fork wrench.

L

eft screw thread, tighten by turning counter clockwise.

9.

Remove the locking pin from the hole.

Inser

t the insert board to reduce the gap between the tool and machine table

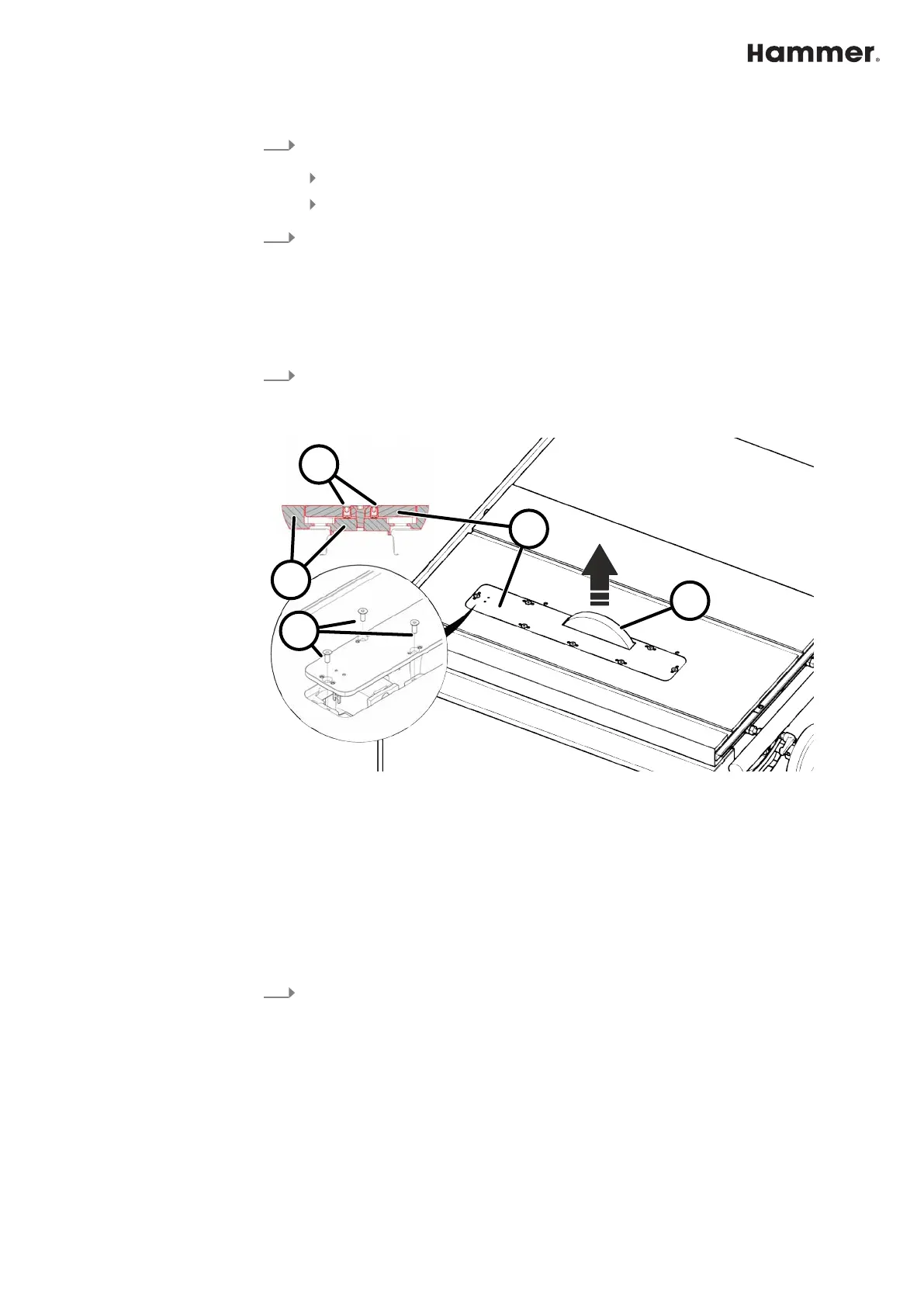

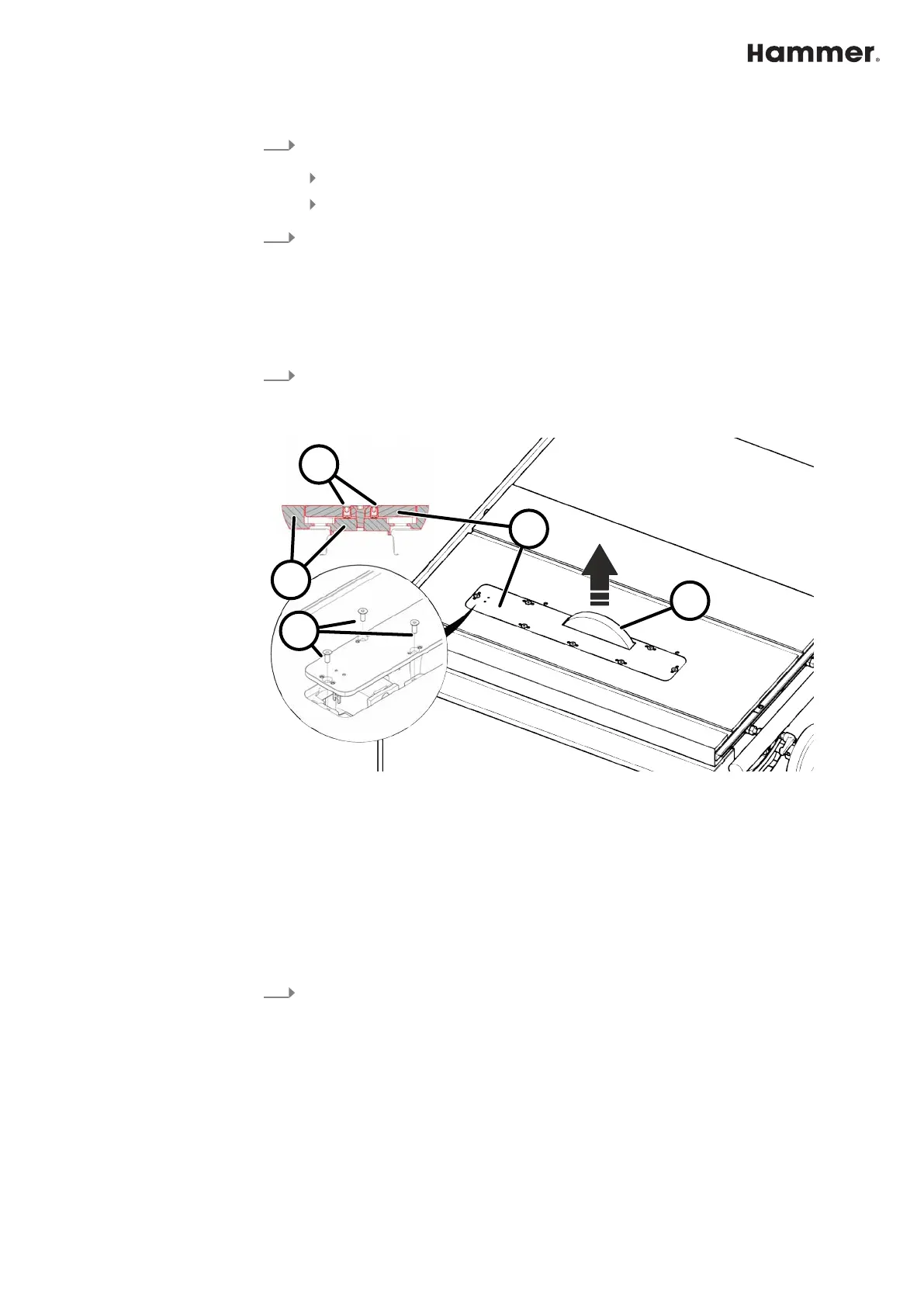

Fig. 18: Inserting the insert board for grooving tool

1 Machine table

2 Insert board (Art.-no. 500-07-206)

3 Grub screws

4 Flat head screws M6x16

5 Grooving tool

Tool:

● Allen key 4 mm

● Allen key 3 mm

1.

Lower the circular saw unit down as far as it goes.

Loading...

Loading...