392 Touch Probe Cycles: Automatic Datum Setting

15.13 DATUM IN ONE AXIS (Cycle 419, DIN/ISO: G419)

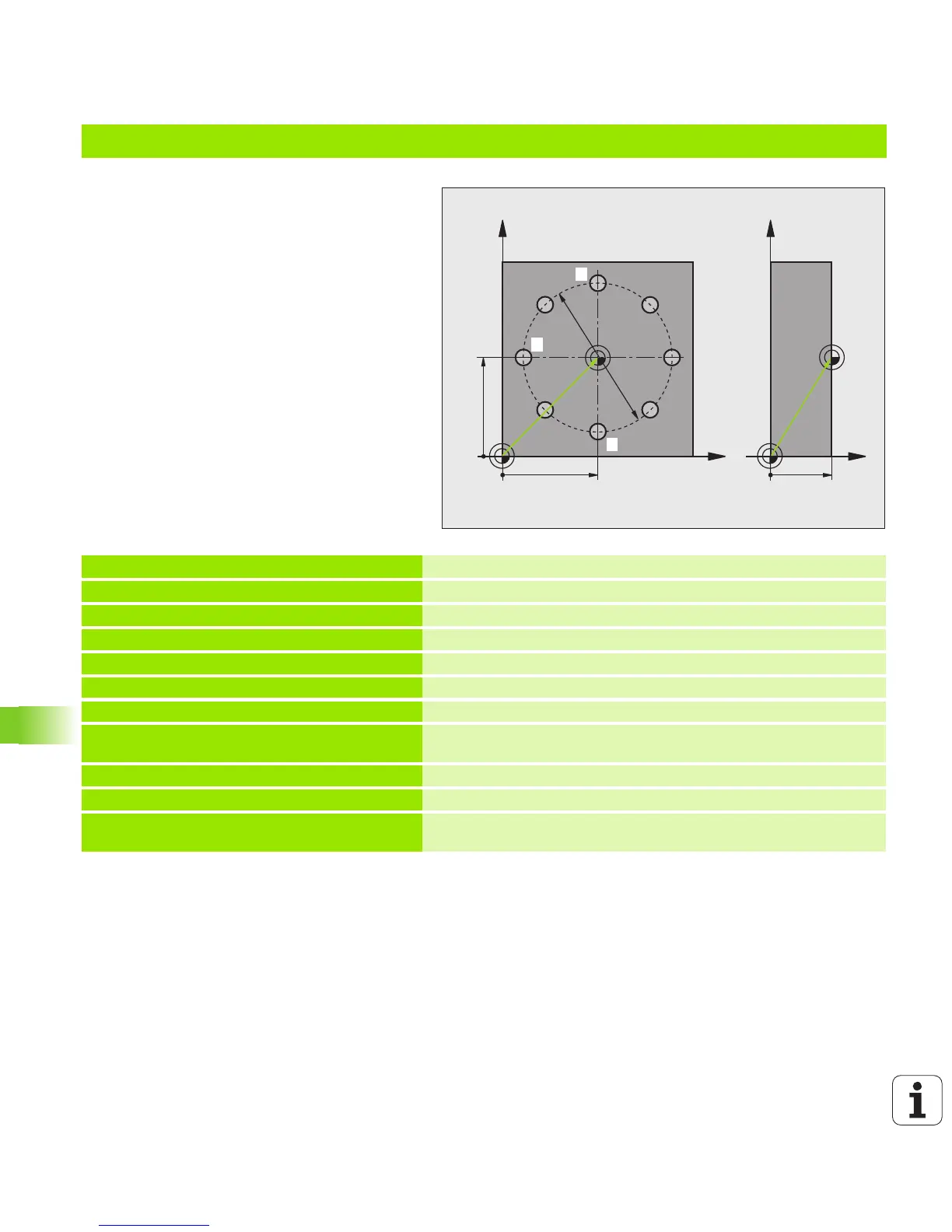

Example: Datum setting on top surface of workpiece and in center of a bolt hole circle

The measured bolt hole center shall be written in

the preset table so that it may be used at a later

time.

0 BEGIN PGM CYC416 MM

1 TOOL CALL 69 Z

Call tool 0 to define the touch probe axis

2 TCH PROBE 417 DATUM IN TS AXIS

Cycle definition for datum setting in the touch probe axis

Q263=+7.5 ;1ST POINT 1ST AXIS

Touch point: X coordinate

Q264=+7.5 ;1ST POINT 2ND AXIS

Touch point: Y coordinate

Q294=+25 ;1ST POINT 3RD AXIS

Touch point: Z coordinate

Q320=0 ;SETUP CLEARANCE

Safety clearance in addition to MP6140

Q260=+50 ;CLEARANCE HEIGHT

Height in the touch probe axis at which the probe can traverse

without collision

Q305=1 ;NO. IN TABLE

Write Z coordinate in line 1

Q333=+0 ;DATUM

Set touch-probe axis to 0

Q303=+1 ;MEAS. VALUE TRANSFER

In the preset table PRESET.PR, save the calculated datum

referenced to the machine-based coordinate system (REF system)

Loading...

Loading...