D2 Drive User Guide v1.8 5. Drive Configuration

HIWIN Mikrosystem Corp. 125

Debounce time setting

The motor positioning may have the overshoot phenomenon, resulting in that the “In-Position”

signal will be instable before the motor reaches the target position. This can be resolved by

setting “Debounce time”. The “In-Position” signal will be sent when the position error enters

“Target radius” and continues to a period of “Debounce time”. The larger “Debounce time” is,

the more stable the “In-Position” signal is, but the larger the time delay is. Through observing

on the oscilloscope, the appropriate “Debounce time” can be set.

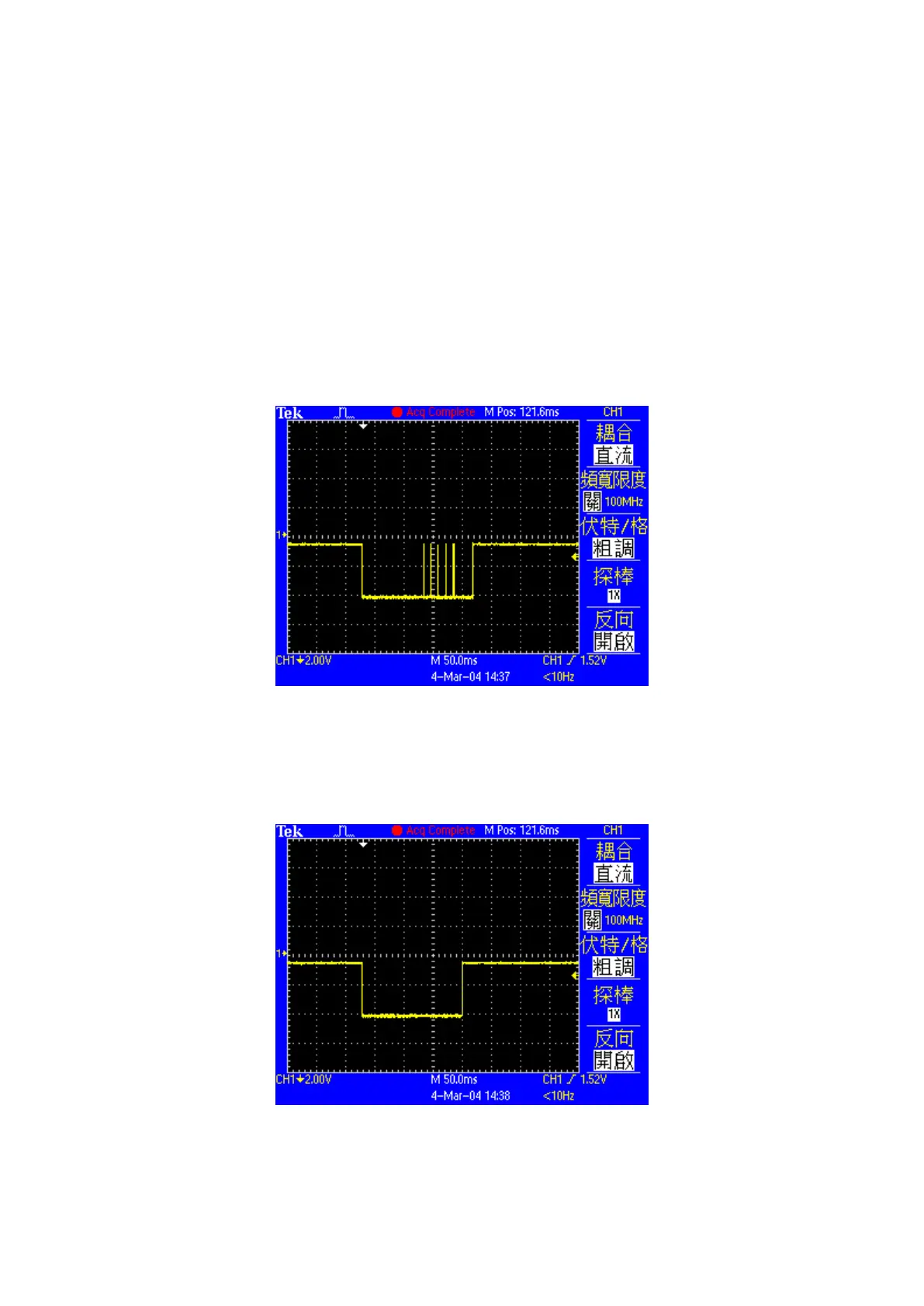

(1) After fixing “Target radius” and setting “Debounce time” to 0 ms, let the motor move

a distance and observe the “In-Position” signal on the oscilloscope, as shown in

Fig. 5-45. When “In-Position” is achieved, the signal is a high level; while when it is

not achieved, the signal is a low level. It can be observed from Fig. 5-45, when the

motor moves to near the target position, there are six protruding pulses (the latter

two are closer). Observing the high-level duration of each protruding pulse, the first

one is about 1.5 ms, the second one is about 1.4 ms, the third one is about 1.4 ms,

the fourth one is about 1.3 ms, and the fifth one and the sixth one are about 1 ms.

Fig. 5-45 In-position signal at “Debounce time” being 0 ms

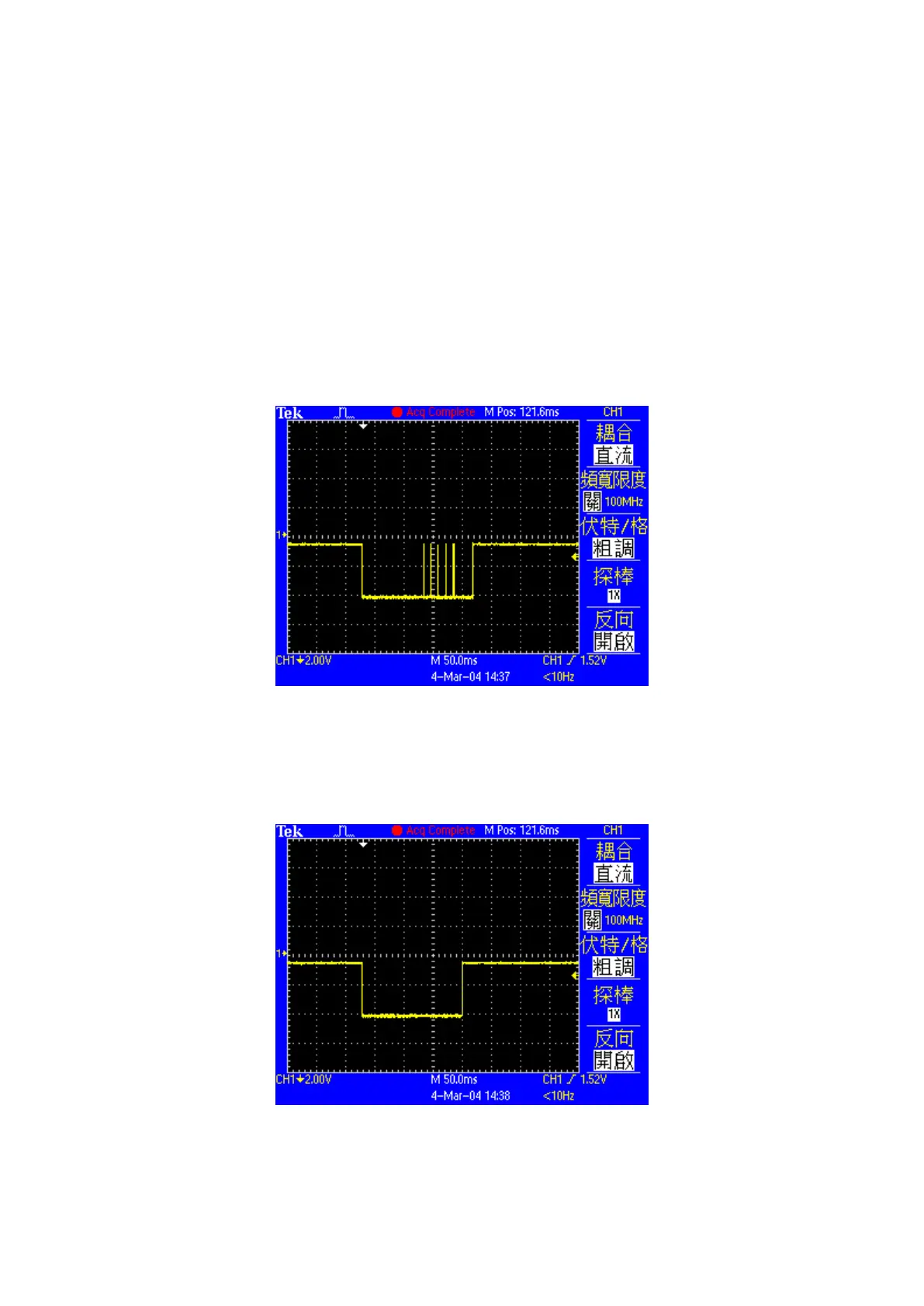

(2) Observing in Fig. 5-45, the widest protruding pulse is 1.5 ms. So, “Debounce time”

can be set to larger than this value. After considering the safety factor, set

“Debounce time” to 3 ms. Let the motor move a distance, the “In-Position” signal is

shown in Fig. 5-46. The instability of “In-Position” signal is improved.

Fig. 5-46 In-position signal at “Debounce time” being 3 ms

Loading...

Loading...