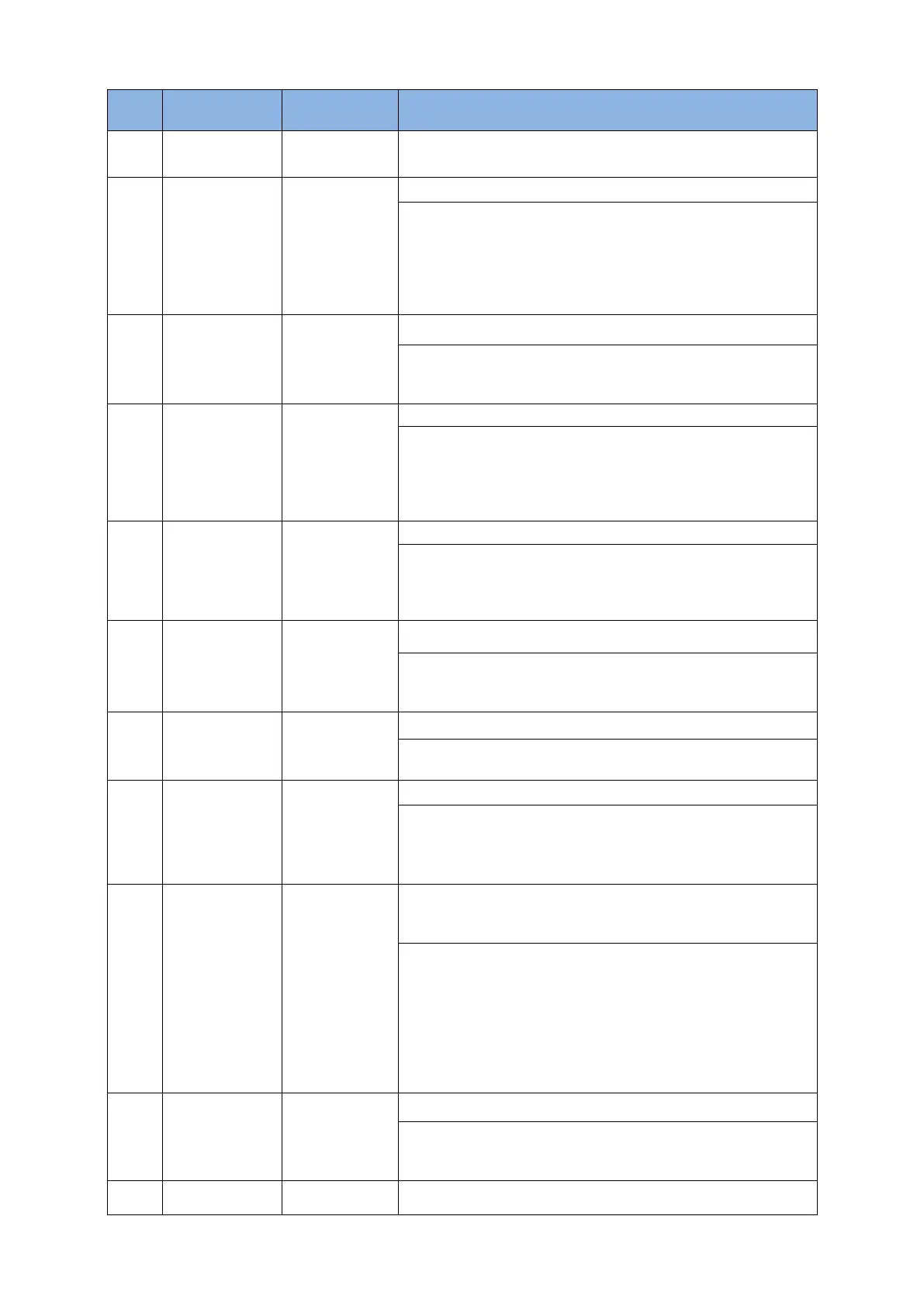

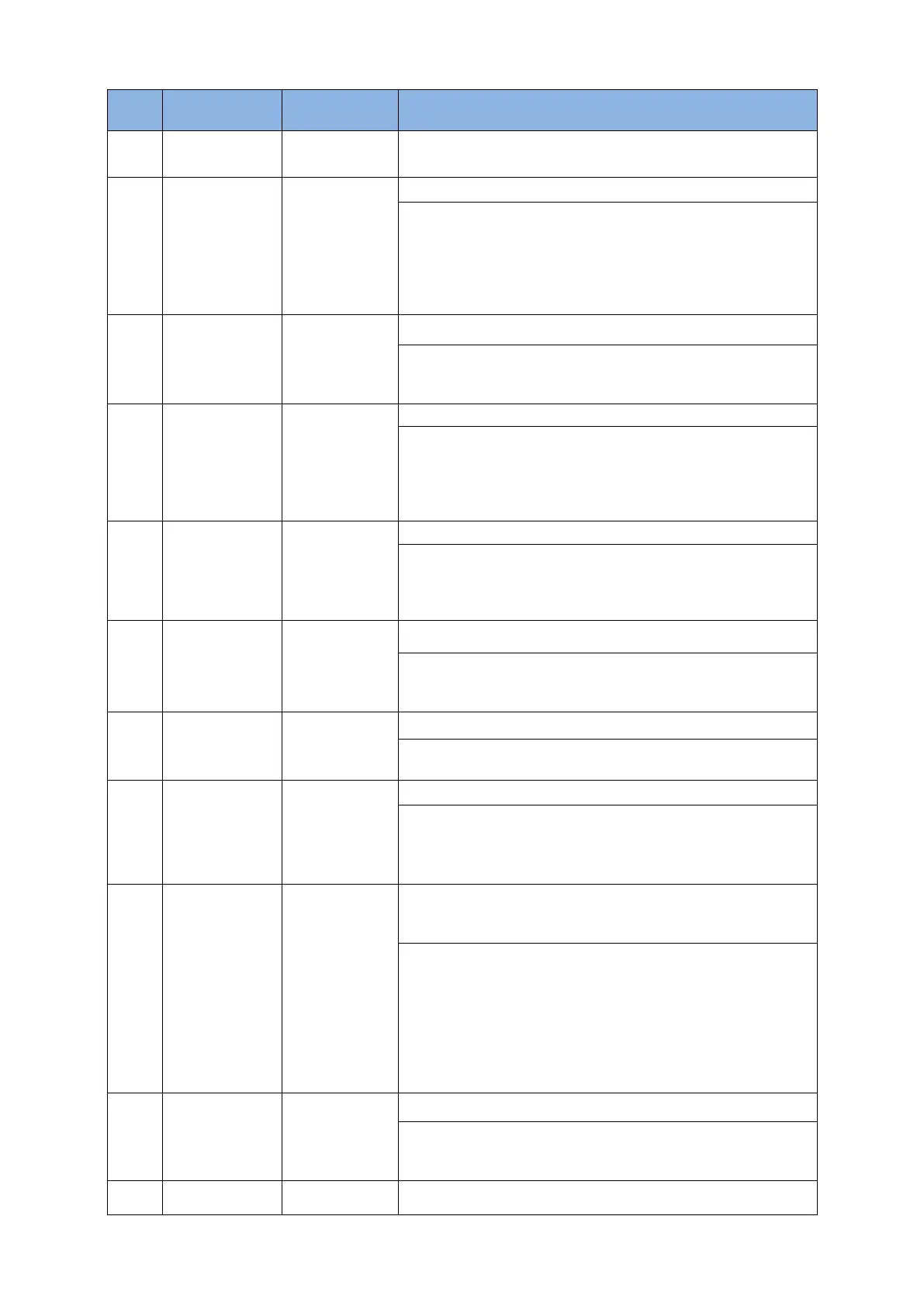

D2 Drive User Guide v1.8 9. Troubleshooting

HIWIN Mikrosystem Corp. 256

Description

Troubleshooting

(1) Check if the connector of UVW cable is loose.

(2) Check if the motor model name is set incorrectly.

Amplifier over

temperature

The drive is over temperature.

(1) Check that the drive is placed in a well-ventilated

location.

(2) Check if the ambient temperature is too high.

(3) Wait for the internal temperature of drive to decrease.

(4) To drive a large load or operate at a high duty cycle,

install the heat sink if needed.

The DC bus in the drive is too small.

Confirm that L1 and L2 of drive are connected to 100 or 220

Vac power source. Use a multimeter to check whether the

input is 100 or 220 Vac.

The 5V power supply of encoder interface is abnormal.

(1) Unplug CN6, CN7, and motor power cable of D2 drive.

Check whether there is still the error of “E10 V5ERR”. If

yes, contact the manufacturer for repair; otherwise, check

if there is a short circuit and then modify the wiring.

(2) Do not hot-plug CN6 and CN7 of D2 drive.

Phase

initialization

error

Motor phase initialization is failed.

(1) Check that the encoder signal is normal and motor

parameters are set correctly.

(2) Check if the payload is too high, the friction is too high,

and whether obstacles are on the way.

Serial Encoder

Communication

Error

The serial encoder communication has an error.

(1) Check that the encoder cable is connected to the drive.

(2) Check that the encoder cable complies with the motor

specification.

The less-wire encoder detects a hall signal error.

Check that the encoder cable is properly connected to the

drive.

The current control has an error.

(1) Check that the motor model name is set correctly.

(2) Check that the current-loop gain (“Kp”) and servo gain

are set appropriately.

(3) Check that the encoder cable is connected correctly.

In the architecture of dual-loop control, the hybrid control

deviation exceeds the allowable maximum of hybrid control

deviation.

(1) Check that the parameter of linear encoder is set

correctly.

(2) Check that the direction of linear encoder is consistent

with the rotary encoder, or if the linear encoder has the

signal interference.

(3) Check if the coupling is loose, the gear is not tightly

engaged, or the pitch tolerance or backlash of screw is

too large.

The STO safety function is triggered.

Reconnect STO to 24 V after the risk has been removed,

and then contact “DSF+” with “DSF-“ for 1 second to release

the error condition.

Drive hardware signals are conflicted abnormally.

Loading...

Loading...