Abbreviations

126 customer.honeywell.com 70-6925

For example, the hot deck control point is reset upward as

the outdoor air temperature decreases. Also know as

“compensation control.”

Restrictor: A device in an air line that limits the flow of air.

Return air: Air entering an air handling system from the

occupied space.

Reverse acting (RA): A reverse-acting thermostat or controller

decreases the branchline pressure on an increase in the

measured variable and increases the branchline pressure on

a decrease in the variable. A reverse-acting valve actuator

retracts the shaft on an increase in branchline pressure and

extends the shaft on a decrease in pressure.

Sensing element: A device that detects and measures the

controlled variable (e.g., temperature, humidity).

Sensor: A device placed in a medium to be measured or

controlled that has a change in output signal related to a

change in the sensed medium.

Sensor Span: The variation in the sensed media that causes

the sensor output to vary between 3 and 15 psi.

Setpoint: The value on the controller scale at which the

controller is set (e.g., the desired room temperature set on a

thermostat). The desired control point.

Supply air: Air leaving an air handling system.

Thermostat: A device that responds to changes in temperature

and outputs a control signal (branchline pressure). Usually

mounted on a wall in the controlled space.

Throttling range: Related to proportional band, and expressed

in values of the controlled variable (e.g., degrees, percent

relative humidity, pounds per square inch) rather than in

percent.

ABBREVIATIONS

The following port abbreviations are used in drawings of relays

and controllers:

B — Branch

C — Common

E — Exhaust

M —Main

O — Normally connected*

X — Normally disconnected*

P — Pilot (P1 and P2 for dual-pilot relays)

S — Sensor (S1 and S2 for dual-input controllers)

N.C. — Normally closed

N.O. — Normally open

* The normally connected and common ports are connected

on a fall in pilot pressure below the relay setpoint, and the

normally disconnected port is blocked. On a rise in pilot

pressure above the relay setpoint, the normally

disconnected and common ports are connected and the

normally connected port is blocked. Refer to Figure 37 in

RELAYS AND SWITCHES.

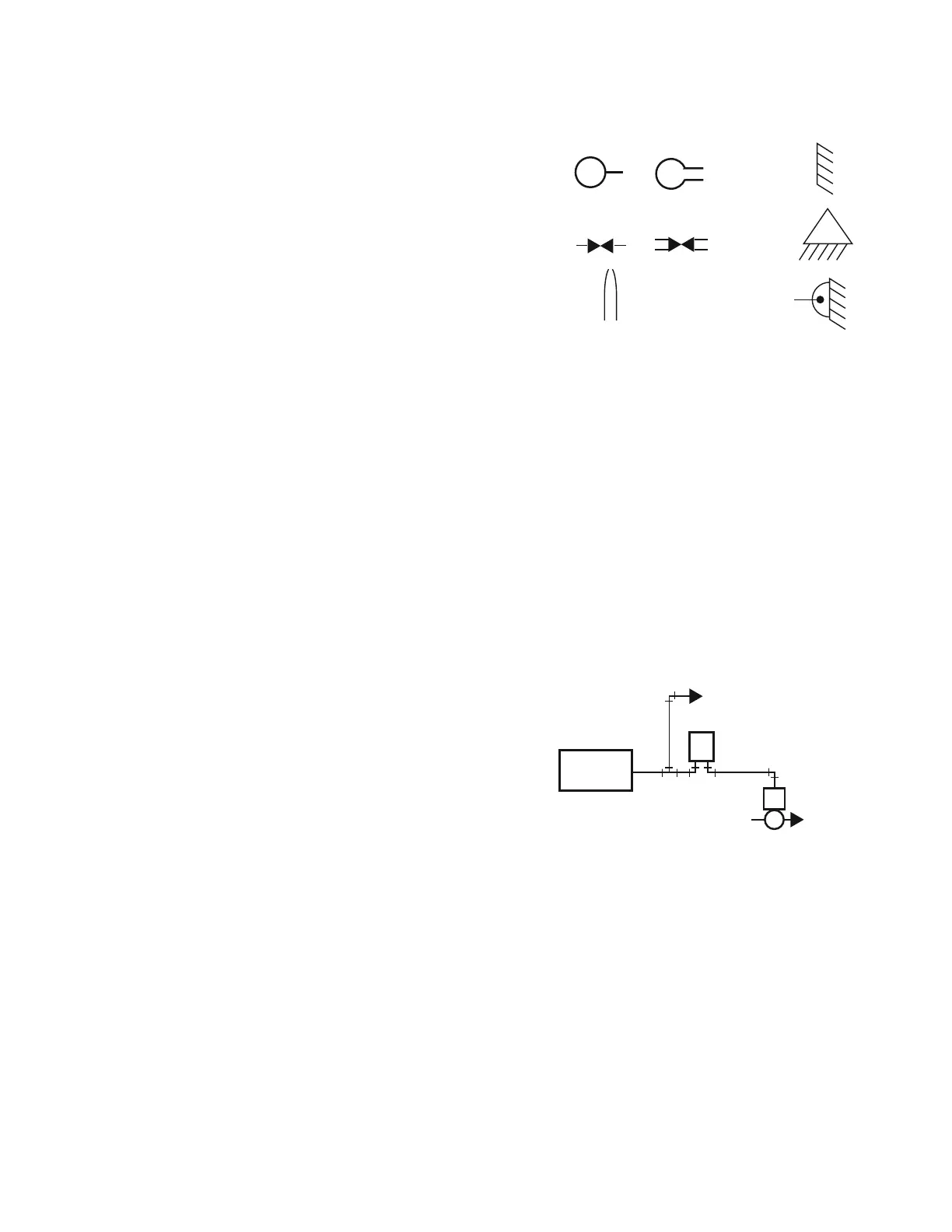

SYMBOLS

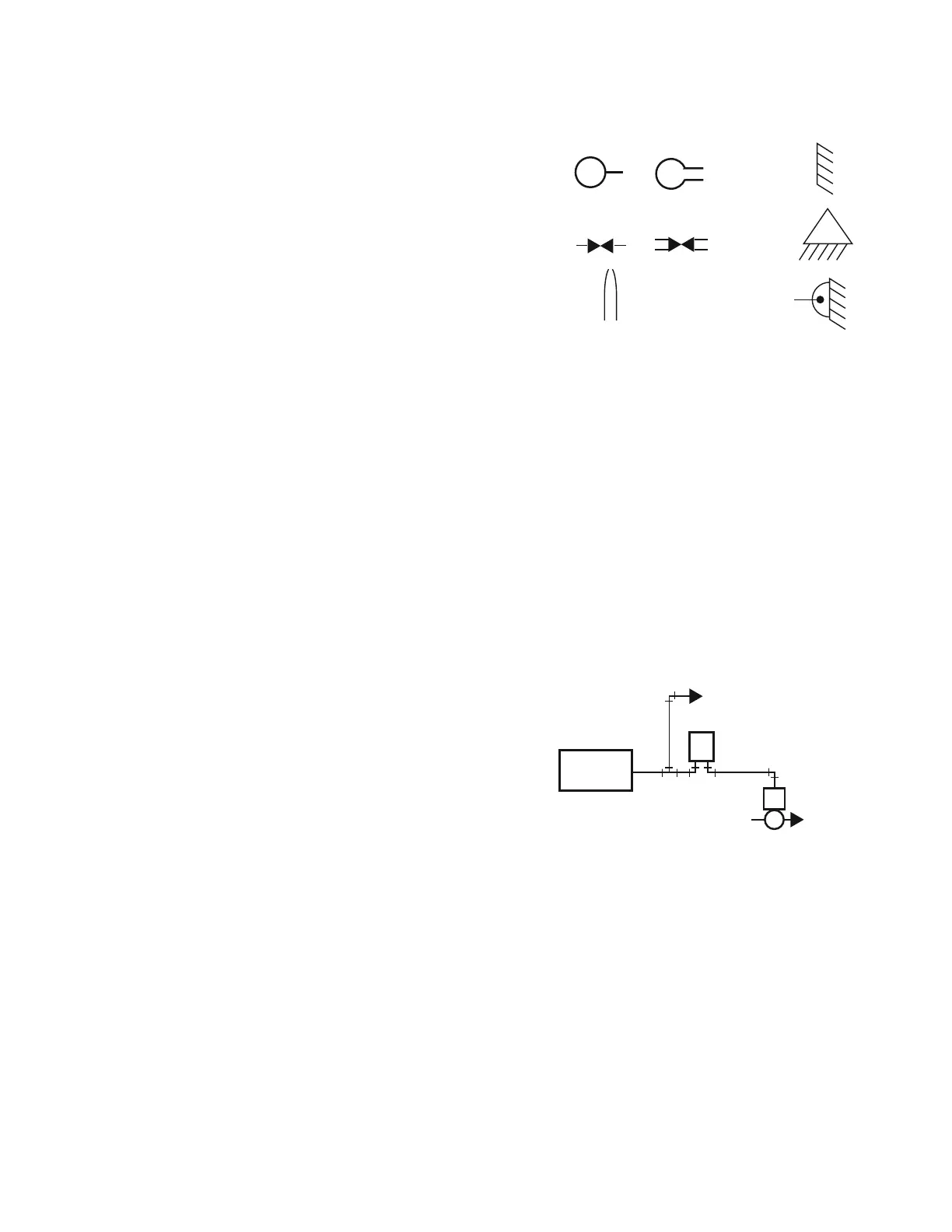

BASIC PNEUMATIC CONTROL SYSTEM

General

A pneumatic control system is made up of the following

elements:

— Compressed air supply system

— Main line distribution system

— Branchlines

— Sensors

— Controllers

—Actuators

— Final control elements (e.g., valves, dampers)

A basic pneumatic control system consists of an air supply, a

controller such as a thermostat, and an actuator positioning a

valve or damper (Fig. 1).

Fig. 1. Basic Pneumatic Control System.

The controller receives air from the main line and regulates its

output pressure (branchline pressure) as a function of the

temperature, pressure, humidity, or other variable. The

branchline pressure from the controller can vary from zero to

full mainline pressure. The regulated branchline pressure

energizes the actuator, which then assumes a position

proportional to the branchline pressure applied. The actuator

usually goes through its full stroke as the branchline pressure

changes from 3 psi to 13 psi. Other pressure ranges are

available.

In a typical control system, the final control element (a valve or

a damper) is selected first because it must produce the desired

control results. For example, a system designed to control the

flow of water through a coil requires a control valve. The type of

valve, however, depends on whether the water is intended for

M

M

OR

OR

MAIN AIR

SUPPLY

RESTRICTOR

NOZZLE

FIXED POINT

FULCRUM

PIVOT POINT

C1082

C2353

COMPRESSED

AIR SUPPLY

SYSTEM

MAIN BRANCH

ACTUATOR

VALVE

THERMOSTAT

TO OTHER

CONTROLLERS

M

B

Loading...

Loading...