Actuators and Final Control Elements

70-6925 137

Humidistats

and

Thermostats Controllers Sensors Relays Switches Actuators Valves Accessories

Engineering

Guide

Cross

Reference

The velocity sensor measures actual velocity and does not

require the conversion of velocity pressure to velocity. Although

the sensor is typically used in duct air velocity applications, it

can accurately sense velocities as low as 100 feet per minute.

Flow-limiting orifices inserted into the sensor sampling tube can

measure velocity ranges up to 3,500 feet per minute.

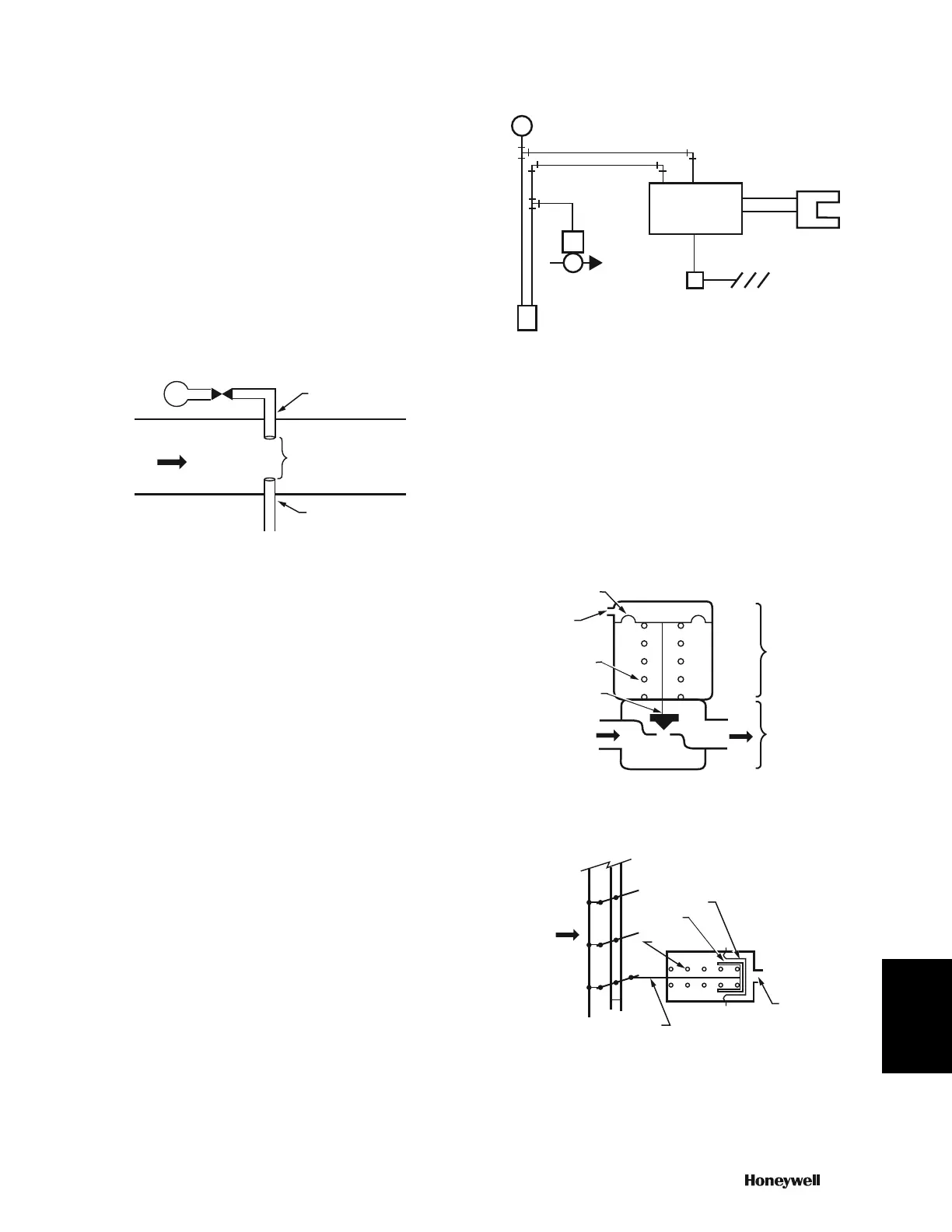

Figure 24 shows the operation of a velocity sensor. A restrictor

supplies compressed air to the emitter tube located in the air

stream to be measured. When no air is flowing in the duct, the

jet of air from the emitter tube impinges directly on the collector

tube and maximum pressure is sensed. Air flowing in the duct

blows the air jet downstream and reduces the pressure on the

collector tube. As the duct air velocity increases, less and less

of the jet enters the collector tube. The collector tube is

connected to a pressure amplifier to produce a usable output

pressure and provide direct or reverse action.

Fig. 24. Velocity Sensor Operation.

A controller connected to the pressure amplifier includes

setpoints for maximum and minimum dual air velocity limits.

This allows the air volume to be controlled between the limits by

a thermostat or another controller.

Two models of the controller are available. One model operates

with a one-pipe, bleed-type thermostat, and the other with a

two-pipe thermostat. The two-pipe model also allows

sequencing for reheat applications.

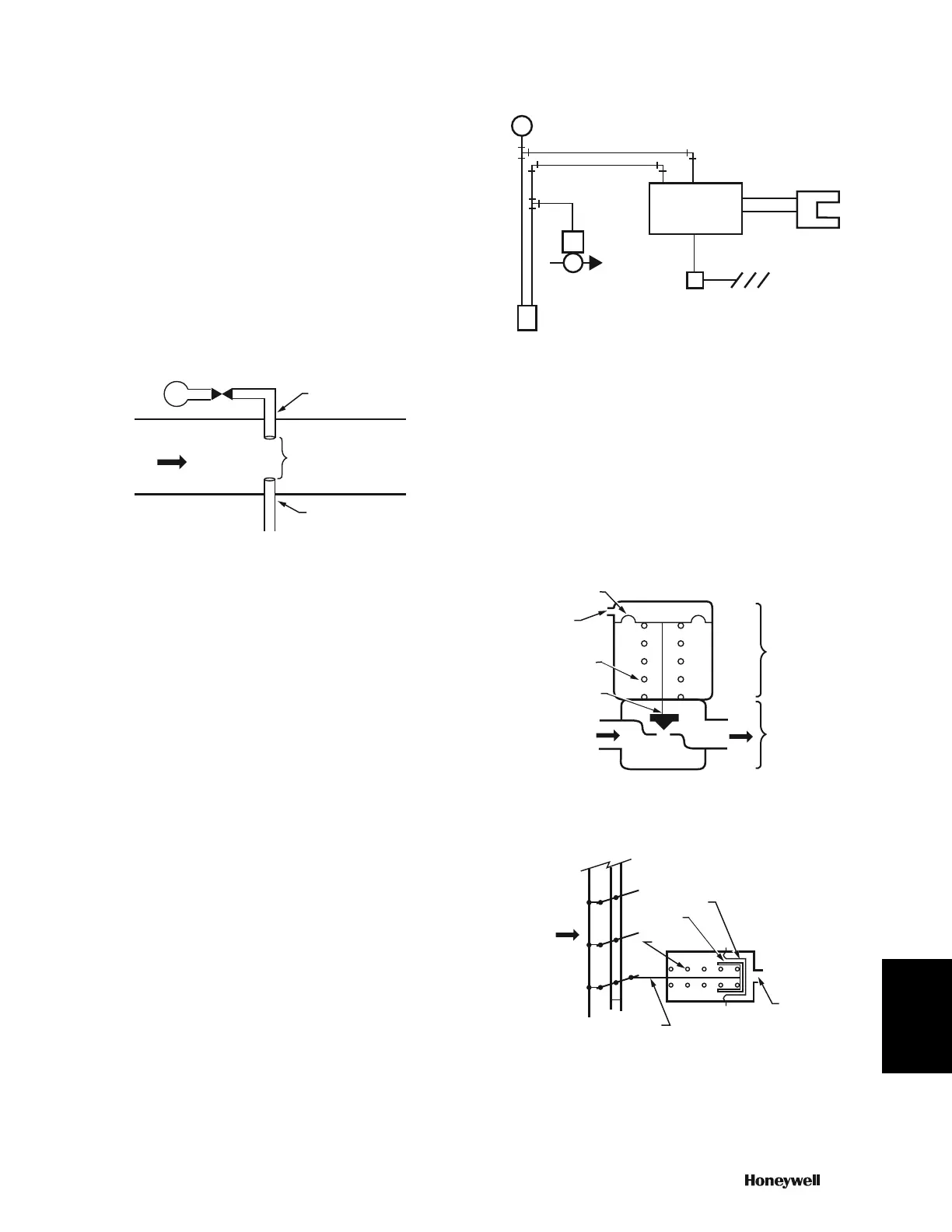

Figure 25 shows a typical application of a thermostat and

velocity controller on a Variable Air Volume (VAV) terminal unit

with hot water reheat. The thermostat senses a change in room

temperature and resets the velocity setpoint of the velocity

controller. The controller repositions the VAV damper to

increase or decrease airflow accordingly. If a change in duct

static pressure modifies the flow, the controller repositions the

actuator to maintain the correct flow. The reheat valve operates

only when the thermostat has reset the velocity setpoint down

to minimum airflow and the thermostat calls for heating.

Fig. 25. VAV Box Velocity Controller Control System.

ACTUATORS AND FINAL CONTROL

ELEMENTS

A pneumatic actuator and final control element such as a valve

(Fig. 26) or damper (Fig. 27) work together to vary the flow of

the medium passing through the valve or damper. In the

actuator, a diaphragm and return spring move the damper push

rod or valve stem in response to changes in branchline

pressure.

Fig. 26. Pneumatic Actuator and Valve.

Fig. 27. Pneumatic Actuator and Damper.

M

AIR FLOW

EMITTER TUBE

GAP

COLLECTOR

TUBE

TO PRESSURE

AMPLIFIER

C2610

M

VELOCITY

SENSOR IN

DUCTWORK

VAV BOX

DAMPER

DAMPER

ACTUATOR

VELOCITY

CONTROLLER

VAV BOX

REHEAT VALVE

ROOM

THERMOSTAT

M10296

BRANCH

LINE

SPRING

VALVE

STEM

INLET

FLOW

OUTLET

FLOW

DIAPHRAGM

VALVE

ACTUATOR

VALVE

M10361

C2611

DAMPER

IRFLOW

PUSH

ROD

DAMPER

ACTUATOR

SPRING

PISTON

ROLLING

DIAPHRAGM

BRANCH

LINE

Loading...

Loading...