Sensor-Controller Systems

136 customer.honeywell.com 70-6925

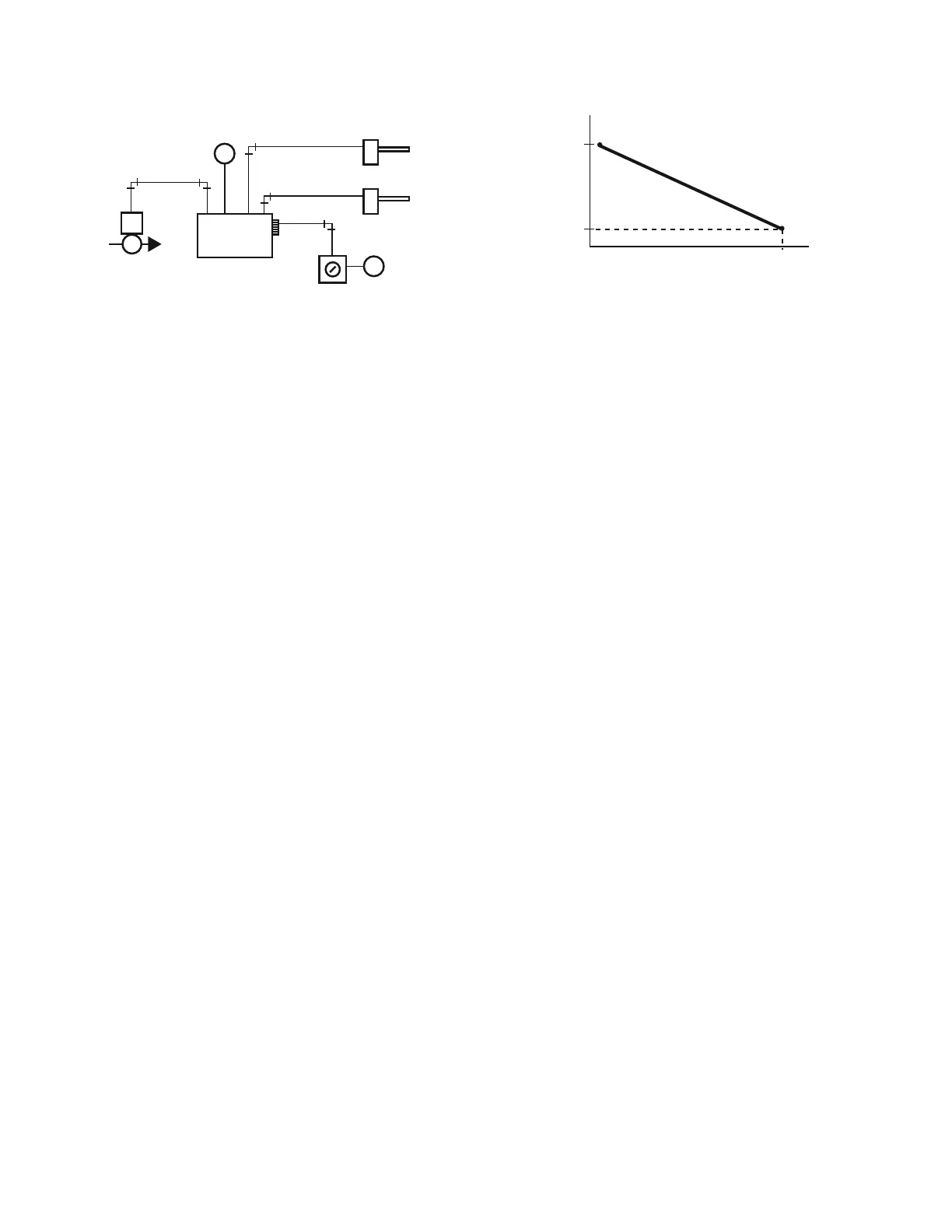

Fig. 22. Dual-Input Controller with

Manual Remote Setpoint.

Proportional-Integral (PI) Controllers

Variations of single-input and dual-input controllers can provide

proportional-integral (PI) control. PI controllers are used in

critical applications that require closer control than a

proportional controller. A PI controller provides close control by

eliminating the deviation from setpoint (offset) that occurs in a

proportional controller system. PI controllers are similar to the

controllers in Figures 21 and 22 and have an additional knob for

adjusting the integral reset time.

Controller Adjustments

Controller operation is adjusted in the following ways:

— Adjusting the setpoint

— Changing between direct and reverse control action

— Adjusting the proportional band (throttling range)

— Adjusting the reset authority

— Adjusting the integral control reset time

The setpoint can be manually adjusted with a dial on the

controller. Remote setpoint adjustment is available for all

controllers. Control action may be direct or reverse, and is field

adjustable. The proportional band setting is typically adjustable

from 2.5 to 50 percent of the primary sensor span and is usually

set for the minimum value that results in stable control. In a

sensor with a span of 200 degrees F, for example, the minimum

setting of 2.5 percent results in a throttling range of 5 degrees F

(0.025 x 200 = 5 degrees F). A change of 5 degrees F is then

required at the sensor to proportionally vary the controller

branchline pressure from 3 to 13 psi. A maximum setting of 50

percent provides a throttling range of 100 degrees F (0.50 x 200

= 100 degrees F).

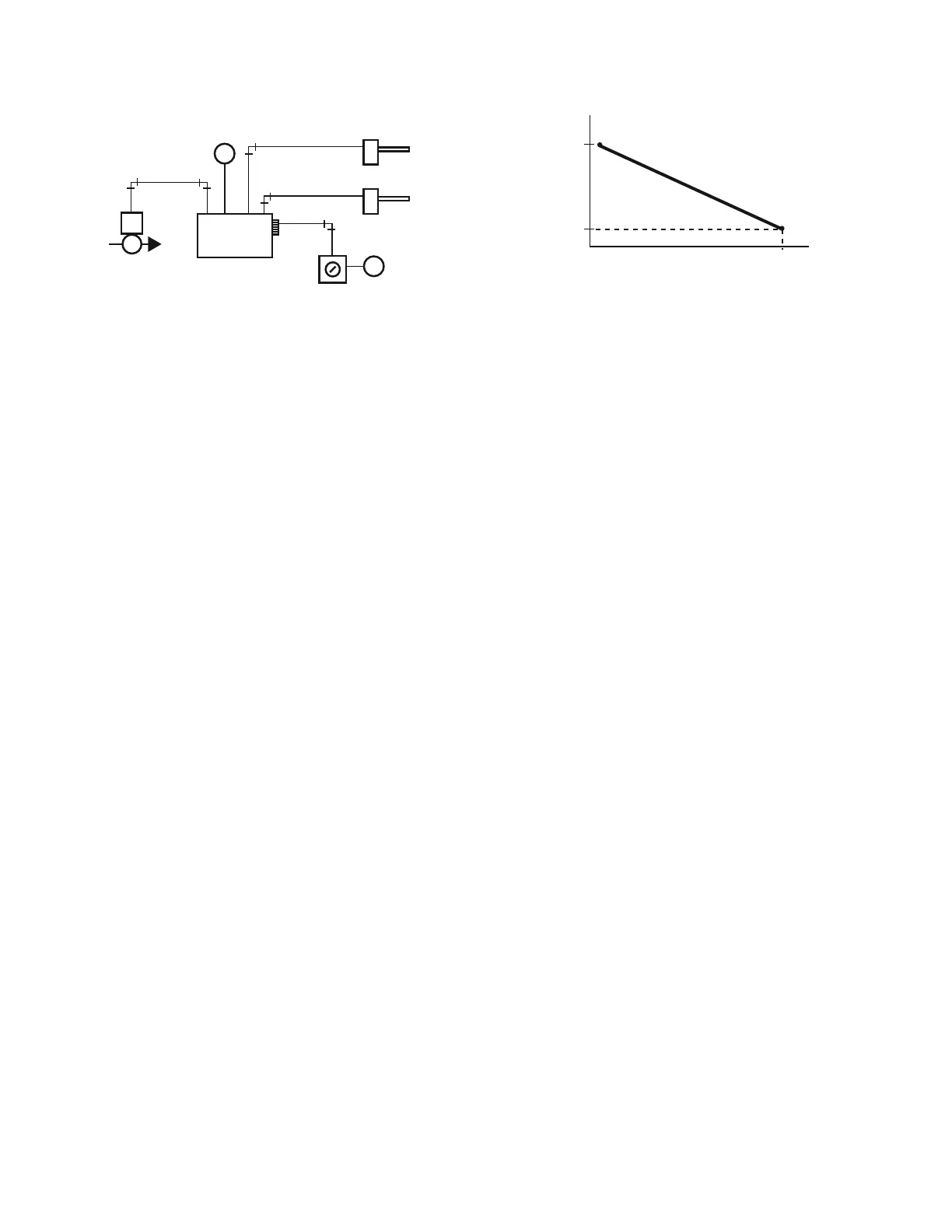

Reset authority, also called “reset ratio”, is the ratio of the effect

of the reset sensor compared to the primary sensor. Figure 23

shows the effect of authority on a typical reset schedule. The

authority can be set from 10 to 300 percent.

Fig. 23. Typical Reset Schedule for

Discharge Air Control.

The integral control reset time determines how quickly the PI

controller responds to a change in the controlled variable.

Proportional correction occurs as soon as the controlled

variable changes. The integral function is timed with the reset

time adjustment. The reset time adjustment is calibrated from

30 seconds to 20 minutes. The proper setting depends on

system response time characteristics.

Pneumatic Sensors

Pneumatic sensors typically provide a direct acting 3 to 15 psi

pneumatic output signal that is proportional to the measured

variable. Any change in the measured variable is reflected as a

change in the sensor output. Commonly sensed variables are

temperature, humidity, and differential pressure. The sensors

use the same sensing elements and principles as the sensors

in the controllers described earlier, but do not include setpoint

and throttling range adjustments. Their throttling range is the

same as their span.

A gage connected to the sensor output can be used to indicate

the temperature, humidity, or pressure being sensed. The gage

scale is calibrated to the sensor span.

Temperature sensors may be vapor-filled, liquid-filled,

averaging capillary, or rod-and-tube. The controller usually

provides restricted air to the sensor.

Humidity sensors measure the relative humidity of the air in a

room (wall-mounted element) or a duct (insertion element).

Nylon is typically used as the sensing element. Humidity

sensors include temperature compensation and operate on a

force-balance principle similar to a wall thermostat.

The low-pressure sensor measures duct static pressure and

differential pressure. When the duct static pressure or the

pressure differential increases, branchline pressure increases.

Velocity Sensor-Controller

The velocity sensor-controller combines a highly sensitive air

velocity sensor with a pneumatic controller to detect and control

airflow regardless of system static pressure. It is used in air

terminal units and other air handling systems. Reverse and

direct-acting models are available for normally closed and

normally open dampers.

M

MANUAL REMOTE

SETPOINT CONTROL

HOT WATER

VALVE

MAIN AIR

(18 PSI)

RESET SENSOR

PRIMARY

SENSOR

M10294

M

DA TEMPERATURE

CONTROL POINT (F)

OUTDOOR AIR TEMPERATURE (F)

COMPENSATION

START POINT

60

0

30

130

C1094

Loading...

Loading...