Basic Pneumatic Control System

70-6925 127

Humidistats

and

Thermostats Controllers Sensors Relays Switches Actuators Valves Accessories

Engineering

Guide

Cross

Reference

heating or cooling, the water pressure, and the control and flow

characteristics required. An actuator is then selected to operate

the final control element. A controller and relays complete the

system. When all control systems for a building are designed,

the air supply system can be sized and designed.

Air Supply and Operation

The main line air supply is provided by an electrically driven

compressor pumping air into a storage tank at high pressure

(Fig. 2). A pressure switch turns the compressor on and off to

maintain the storage tank pressure between fixed limits. The

tank stores the air until it is needed by control equipment. The

air dryer removes moisture from the air, and the filter removes

oil and other impurities. The pressure reducing valve (PRV)

typically reduces the pressure to 18 to 22 psi. For two-pressure

(day/night) systems and for systems designed to change from

direct to reverse acting (heating/cooling), the PRV switches

between two pressures, such as 13 and 18 psi. The maximum

safe air pressure for most pneumatic controls is 25 psi.

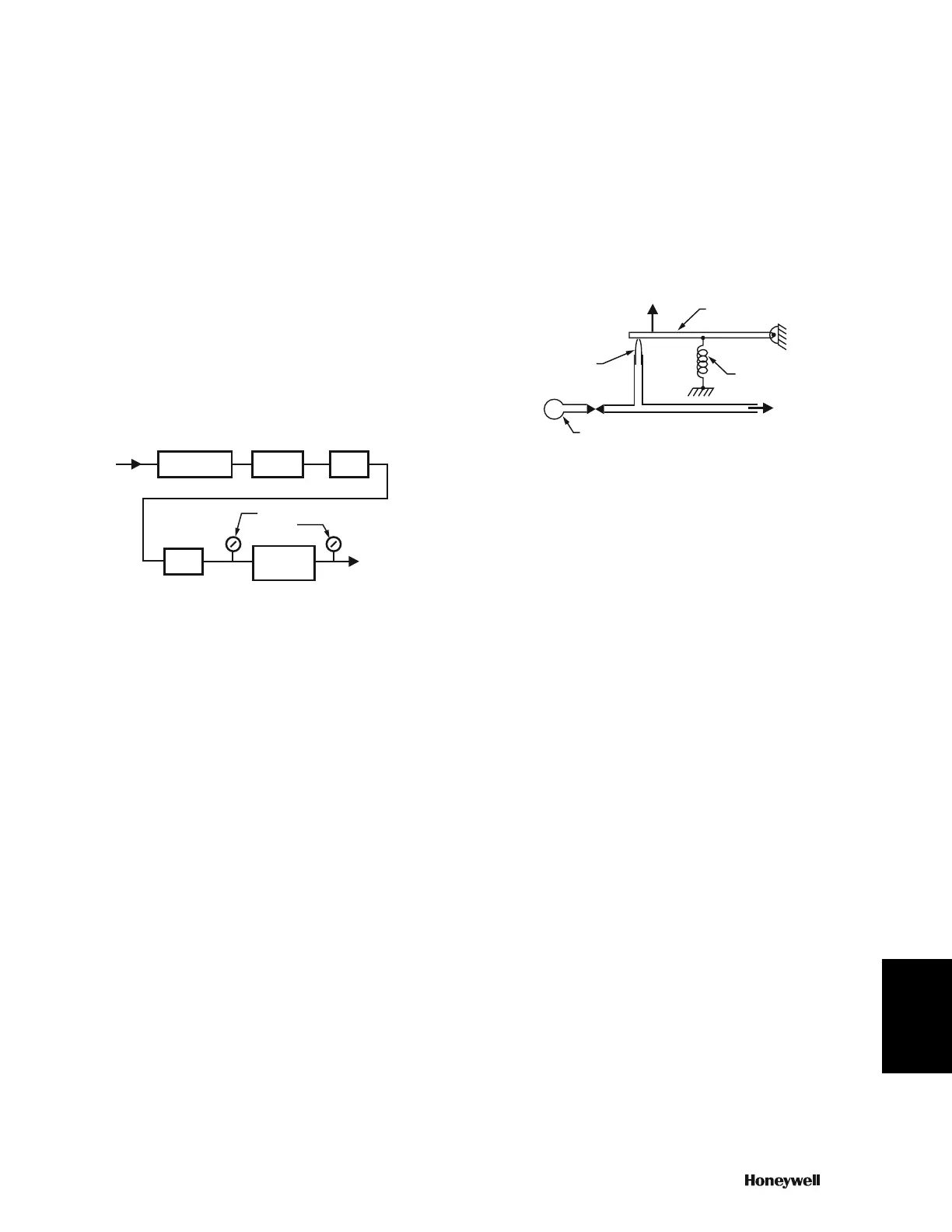

Fig. 2. Compressed Air Supply System.

From the PRV, the air flows through the main line to the

controller (in Figure 1, a thermostat) and to other controllers or

relays in other parts of the system. The controller positions the

actuator. The controller receives air from the main line at a

constant pressure and modulates that pressure to provide

branchline air at a pressure that varies according to changes in

the controlled variable, as measured by the sensing element.

The controller signal (branchline pressure) is transmitted via the

branchline to the controlled device (in Figure 1, a valve

actuator). The actuator drives the final control element (valve)

to a position proportional to the pressure supplied by the

controller.

When the proportional controller changes the air pressure to

the actuator, the actuator moves in a direction and distance

proportional to the direction and magnitude of the change at the

sensing element.

Restrictor

The restrictor is a basic component of a pneumatic control

system and is used in all controllers. A restrictor is usually a

disc with a small hole inserted into an air line to restrict the

amount of airflow. The size of the restrictor varies with the

application, but can have a hole as small as 0.003 inches.

Nozzle-Flapper Assembly

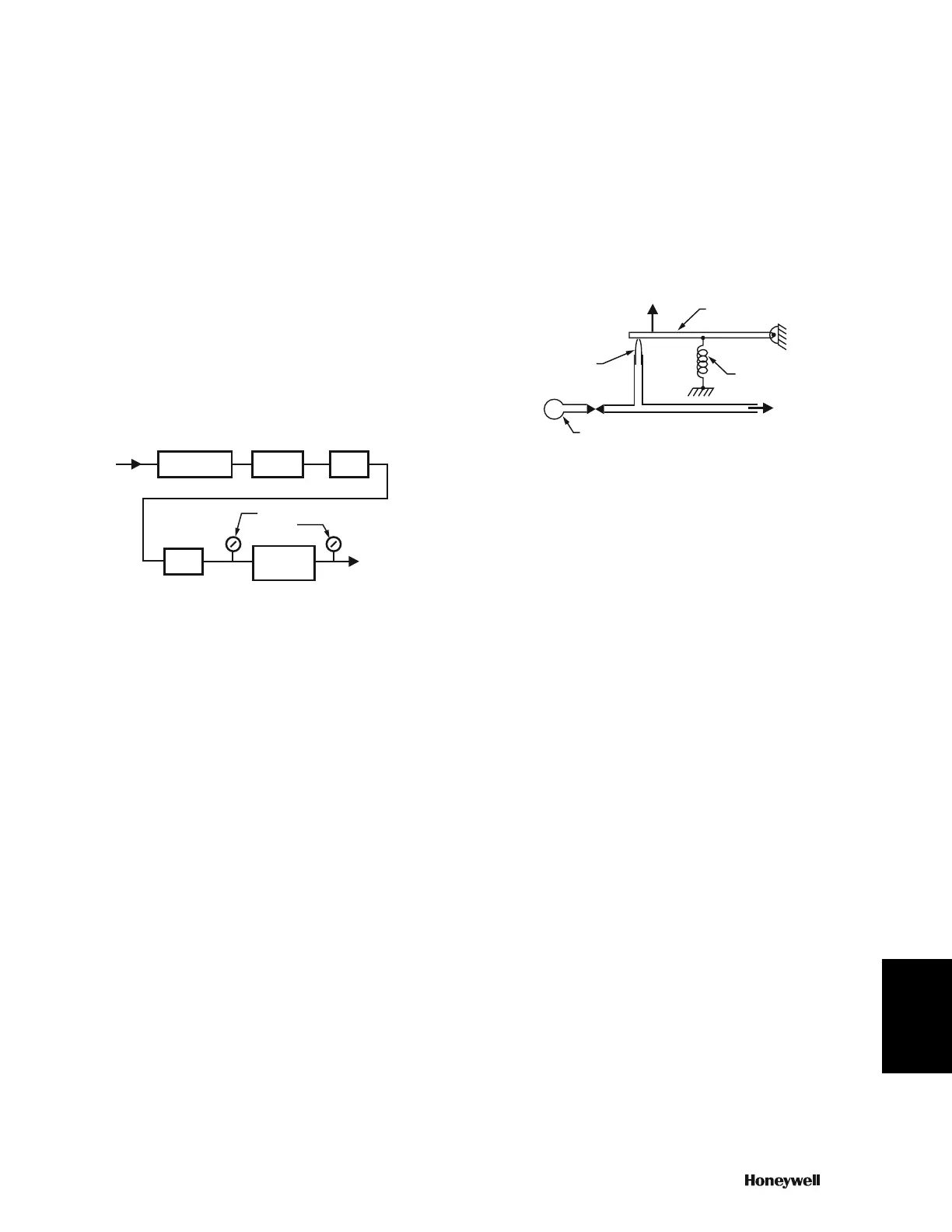

The nozzle-flapper assembly (Fig. 3) is the basic mechanism

for controlling air pressure to the branchline. Air supplied to the

nozzle escapes between the nozzle opening and the flapper. At

a given air supply pressure, the amount of air escaping is

determined by how tightly the flapper is held against the nozzle

by a sensing element, such as a bimetal. Thus, controlling the

tension on the spring also controls the amount of air escaping.

Very little air can escape when the flapper is held tightly against

the nozzle.

Fig. 3. Nozzle-Flapper Assembly with Restrictor.

To create a branchline pressure, a restrictor (Fig. 3) is required.

The restrictor and nozzle are sized so that the nozzle can

exhaust more air than can be supplied through the restrictor

when the flapper is off the nozzle. In that situation, the

branchline pressure is near zero. As the spring tension

increases to hold the flapper tighter against the nozzle,

reducing the air escaping, the branchline pressure increases

proportionally. When the spring tension prevents all airflow from

the nozzle, the branchline pressure becomes the same as the

mainline pressure (assuming no air is flowing in the branchline).

This type of control is called a “bleed” control because air

“bleeds” continuously from the nozzle.

With this basic mechanism, all that is necessary to create a

controller is to add a sensing element to move the flapper as

the measured variable (e.g., temperature, humidity, pressure)

changes. Sensing elements are discussed later.

Pilot Bleed System

The pilot bleed system is a means of increasing air capacity as

well as reducing system air consumption. The restrictor and

nozzle are smaller in a pilot bleed system than in a nozzle

flapper system because in a pilot bleed system they supply air

only to a capacity amplifier that produces the branchline

pressure (Fig. 4). The capacity amplifier is a pilot bleed

component that maintains the branchline pressure in proportion

to the pilot pressure but provides greater airflow capacity.

AIR

SUPPLY

IN

AIR

COMPRESSOR

STORAGE

TANK

AIR

DRYER

FILTER

PRESSURE

GAGES

PRESSURE

REDUCING

VALVE

MAIN AIR TO

PNEUMATIC

CONTROL

SYSTEM

C2616-1

M

SENSOR

FORCE

FLAPPER

SPRING

BRANCH

RESTRICTOR

AIR SUPPLY

NOZZLE

C1084

Loading...

Loading...