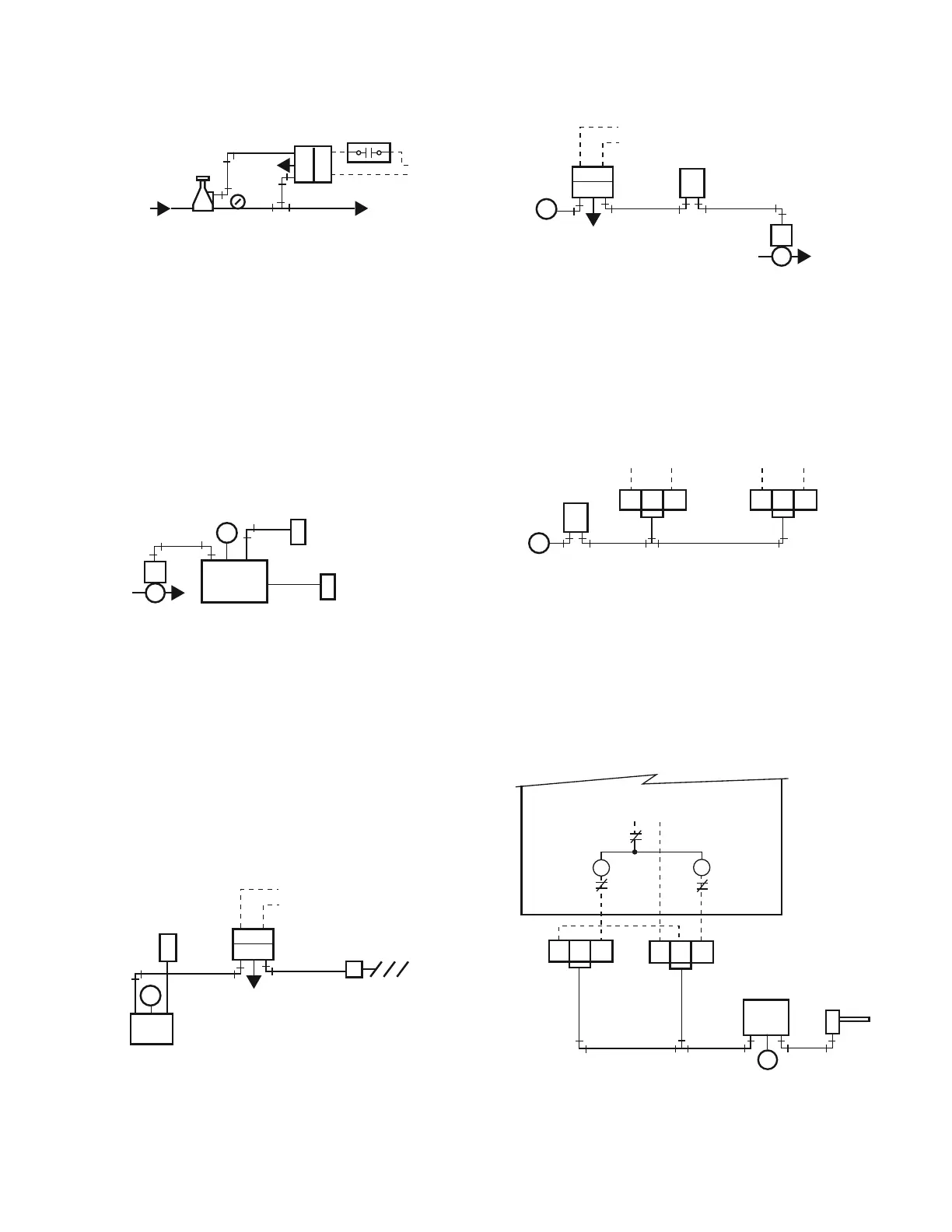

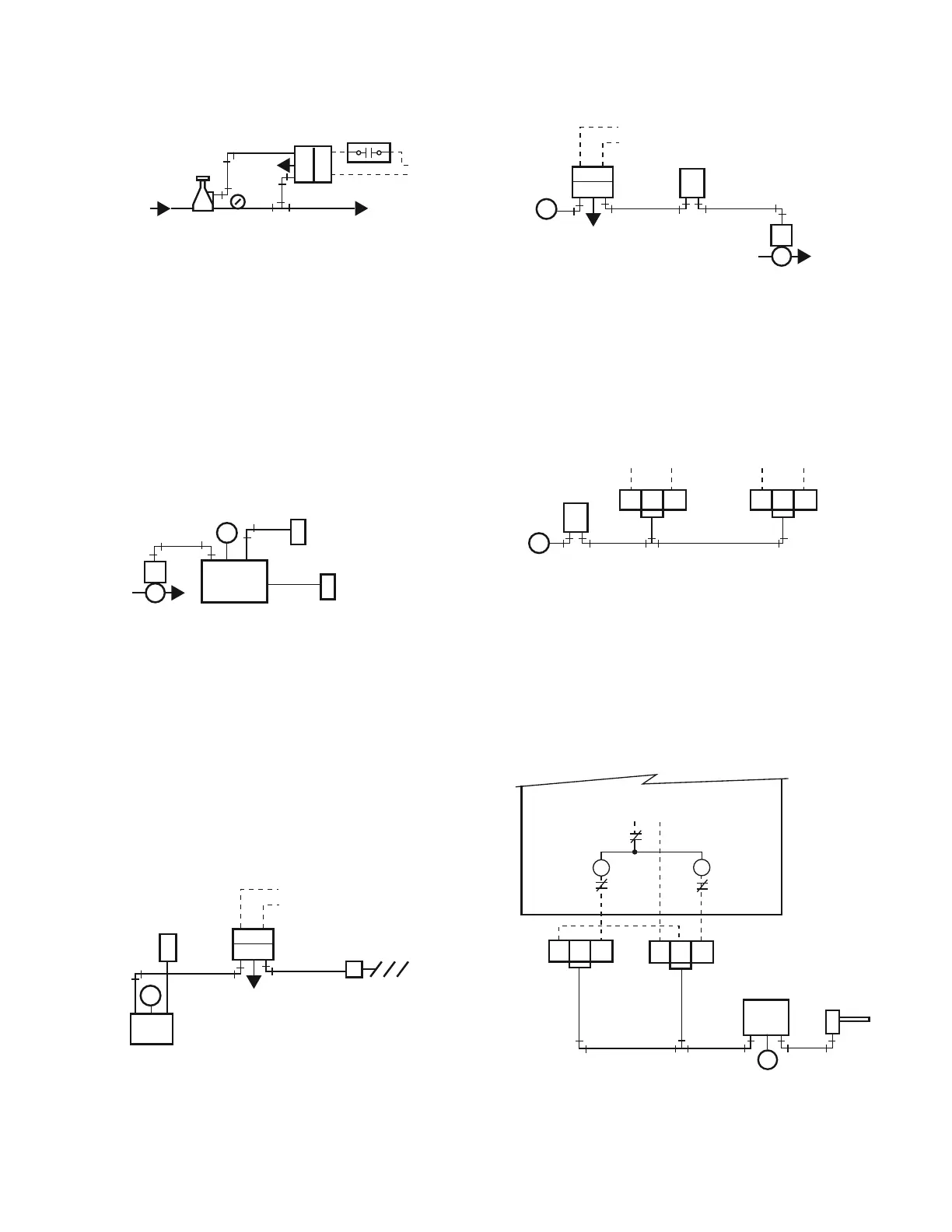

Pneumatic Control Combinations

150 customer.honeywell.com 70-6925

Fig. 66. Two-Pressure Main Supply System

with Automatic Changeover.

Compensated Control System

In a typical compensated control system (Fig. 67), a dual-input

controller increases or decreases the temperature of the supply

water as the outdoor temperature varies. In this application, the

dual-input controller resets the water temperature setpoint as a

function of the outdoor temperature according to a preset

schedule. The system then provides the scheduled water

temperature to the convectors, fan-coil units, or other heat

exchangers in the system.

Fig. 67. Compensated Supply Water System

Using Dual-Input Controller.

Electric-Pneumatic Relay Control

Figure 68 shows one use of an E/P relay in a pneumatic control

circuit. The E/P relay connects to a fan circuit and energizes

when the fan is running and de-energizes when the fan turns

off, allowing the outdoor air damper to close automatically when

the fan turns off. The relay closes off the controller branchline,

exhausts the branchline going to the damper actuator, and

allows the damper to go to its normal (closed) position. Figure

69 shows an E/P relay application that shuts down an entire

control system.

Fig. 68. Simple E/P Relay Combination.

Fig. 69. E/P Relay Combination for System Shutdown.

Pneumatic-Electric Relay Control

A P/E relay provides the interlock when a pneumatic controller

actuates electric equipment. The relays can be set for any

desired pressure. Figure 70 shows two P/E relays sequenced

to start two fans, one at a time, as the fans are needed.

Fig. 70. P/E Relays Controlling Fans in Sequence.

On a rise in temperature, Relay 1 puts Fan 1 in operation as the

thermostat branchline pressure reaches 7 psi. Relay 2 starts

Fan 2 when the controller branchline pressure reaches 12 psi.

On a decrease in branchline pressure, Relay 2 stops Fan 2 at

10 psi branchline pressure, and Relay 1 stops Fan 1 at 5 psi

branchline pressure.

Figure 71 shows two spdt P/E relays starting and stopping a

two-speed fan to control condenser water temperature.

Fig. 71. Two-Speed Fan Operated by P/E Relays.

FROM

COMPRESSOR

TWO-PRESSURE

REDUCING VALVE

X = NORMALLY DISCONNECTED

O = NORMALLY CONNECTED

EXH

MAIN

AIR

C2376

C

O

X

ELECTRIC

POWER

THERMOSTAT

OR TIME CLOCK

E/P RELAY

GAUGE

M

VALVE

HOT WATER SUPPLY

TEMPERATURE

SENSOR

OUTDOOR AIR

TEMPERATURE

SENSOR

CONTROLLER

B M S

1

S

2

C2356

EXH

M

XOC

MIXED AIR

SENSOR

BMS

FAN

VOLTAGE

E/P

RELAY

N.C. DAMPER

ACTUATOR

N.C. DAMPER

C2361

DA CONTROLLER

C2358

EXH

N.C.

VALVE

THERMOSTAT

M

B

M

XO

C

SYSTEM

INTERLOCK

VOLTAGE

E/P RELAY

THERMOSTAT

M

B

M

C N.C. N.O.

WIRED TO

START FAN 1

P/E RELAYS

SET

5-7 PSI

SET

10-12 PSI

C N.C. N.O.

WIRED TO

START FAN 2

C2359

M

B M S

C N.C.

N.O.

DA

CONTROLLER

P/E RELAY 2

SET 12-14 PSI

C N.C.

N.O.

COOLING TOWER

FAN STARTER

CONTROL VOLTAGE

OVERLOAD

LOW SPEED

HIGH AUXILIARY

LOW AUXILIARY

HIGH SPEED

FAN STARTER

P/E RELAY 1

SET 7-9 PSI

SENSOR IN

CONDENSER

WATER

C2367

Loading...

Loading...