Air Supply Equipment

70-6925 131

Humidistats

and

Thermostats Controllers Sensors Relays Switches Actuators Valves Accessories

Engineering

Guide

Cross

Reference

outdoor air is available. After the air is compressed, cooling and

settling actions in the tank condense some of the excess

moisture and allow fallout of the larger oil droplets generated by

the compressor pump.

A high pressure safety relief valve which opens on excessively

high tank pressures is also required. A hand valve or automatic

trap periodically blows off any accumulated moisture, oil

residue, or other impurities that collect in the bottom of the tank.

Air Drying Techniques

General

Air should be dry enough to prevent condensation.

Condensation causes corrosion that can block orifices and

valve mechanisms. In addition, dry air improves the ability of

filters to remove oil and dirt.

Moisture in compressed air is removed by increasing pressure,

decreasing temperature, or both. When air is compressed and

cooled below its saturation point, moisture condenses. Draining

the condensate from the storage tank causes some drying of

the air supply, but an air dryer is often required.

An air dryer is selected according to the amount of moisture in

the air and the lowest temperature to which an air line will be

exposed. For a chart showing temperature and moisture

content relationships at various air pressures, refer to the

General Engineering Data section.

Dry Air Requirement

The coldest ambient temperature to which tubing is exposed is

the criterion for required dryness, or dew point. Dew point is the

temperature at which moisture starts to condense out of the air.

The coldest winter exposure is normally a function of outdoor

air temperature. Summer exposure is normally a function of

temperature in cold air ducts or air conditioned space. The

typical coldest winter application is an air line and control device

(e.g., damper actuator) mounted on a rooftop air handling unit

and exposed to outdoor air temperatures (Fig. 12). The second

coldest winter exposure is an air line run in a furred ceiling or

outside wall.

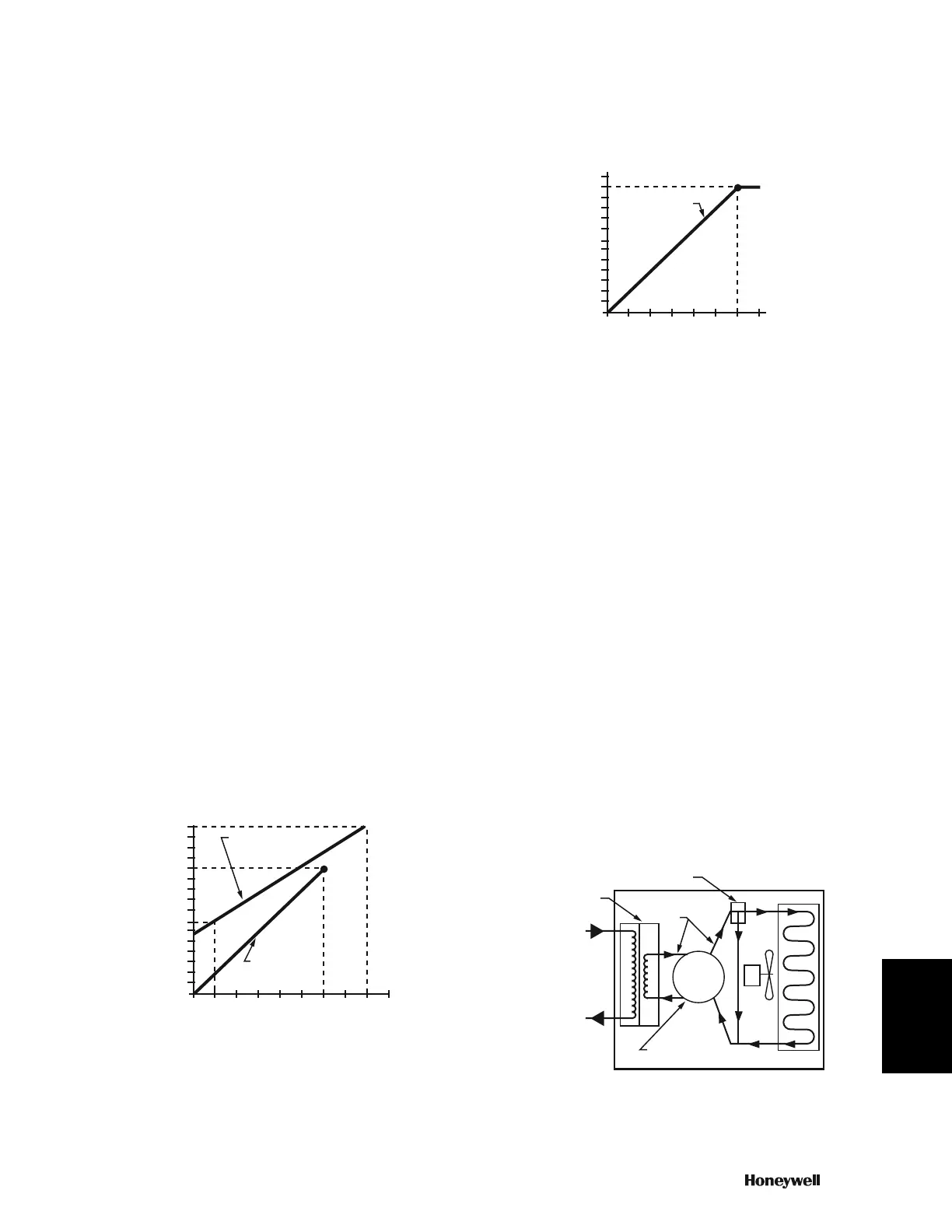

Fig. 12. Winter Dew Point Requirement.

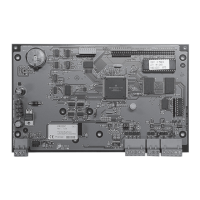

A typical summer minimum dew point application is a cold air

plenum. Figure 13 shows a 50F plenum application along with

winter requirements for a year-round composite.

Fig. 13. Twelve-Month Composite

Dew Point Requirement.

CONDENSING DRYING

The two methods of condensing drying are high-pressure

drying and refrigerant drying.

High-Pressure Drying

High-pressure drying may be used when main air piping is kept

away from outside walls and chilling equipment. During

compression and cooling to ambient temperatures, air gives up

moisture which then collects in the bottom of the storage tank.

The higher the tank pressure, the greater the amount of

moisture that condenses. Maintaining a high pressure removes

the maximum amount of moisture. The compressor should

have a higher operating pressure than is required for air supply

purposes only. However, higher air pressure requires more

energy to run the compressor. The tank must include a manual

drain valve or an automatic trap to continually drain off

accumulated moisture. With tank pressures of 70 to 90 psi, a

dew point of approximately 70F at 20 psi can be obtained.

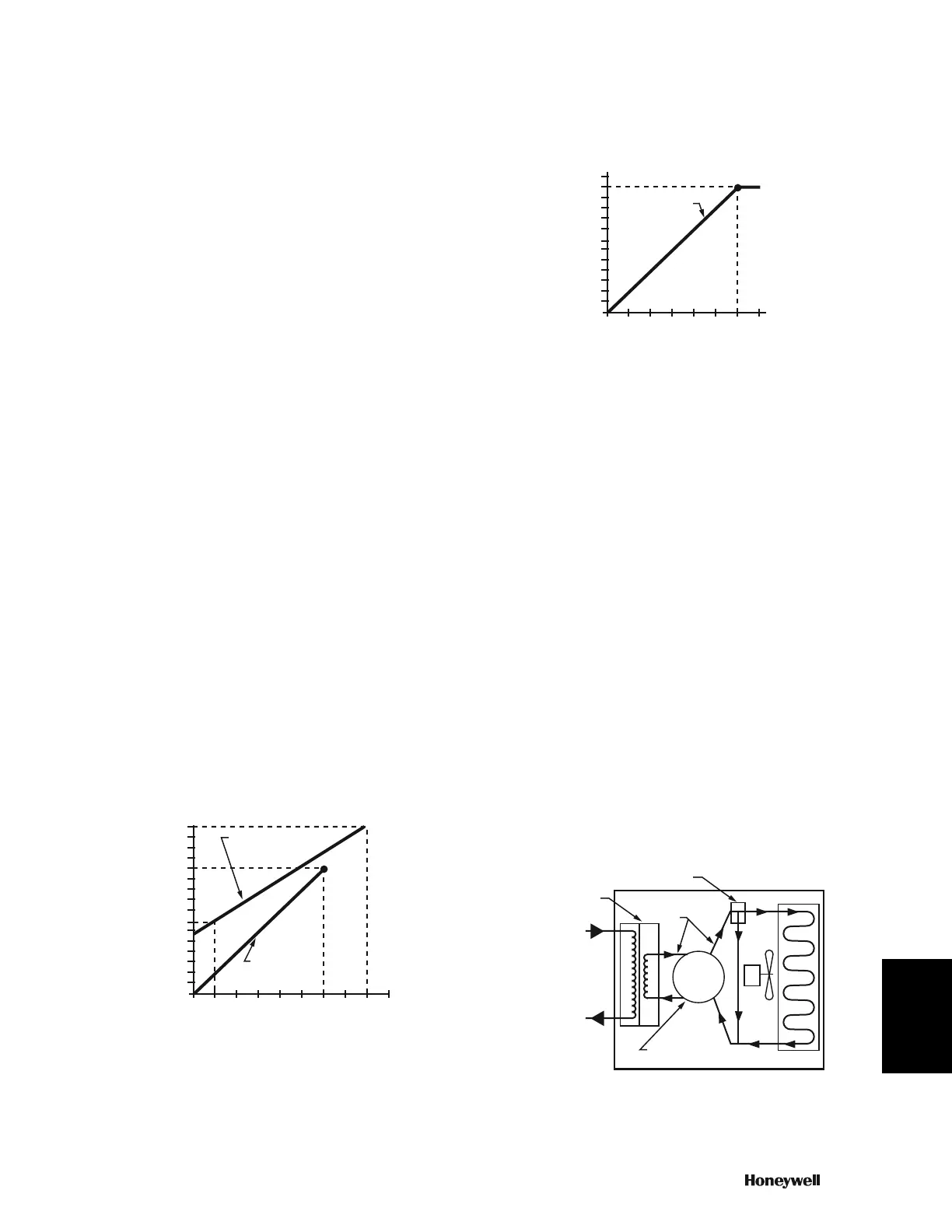

Refrigerant Drying

Lowering air temperature reduces the ability of air to hold water.

The refrigerated dryer (Fig. 14) is the most common means of

obtaining dry, compressed air and is available in several

capacities. It provides the greatest system reliability and

requires minimal maintenance.

Fig. 14. Typical Refrigerant Dryer Airflow Diagram.

70

60

50

40

30

20

10

0

-10

-10 0 10 20 30 40 50 60 70 80

C1098

OUTDOOR AIR TEMPERATURE (F)

REQUIRED MAXIMUM

DEWPOINT OF MAIN AIR (F)

24

TUBING IN

FURRED

CEILING

TUBING AT

OUTDOOR AIR

TEMPERATURE

50

40

30

20

10

0

-10

-10 0 10 20 30 40 50 60

C1099

OUTDOOR AIR TEMPERATURE (F)

REQUIRED MAXIMUM

DEWPOINT OF MAIN AIR (F)

SUMMER REQUIREMENT

COLD AIR PLENUM

WINTER

REQUIREMENT

AT OUTDOOR AIR

TEMPERATURE

HOT GAS

BYPASS

CONTROL

HEAT

EXCHANGER

AIR IN

AIR OUT

REFRIGERANT

LINES

REFRIGERATION

UNIT

CONDENSOR

REFRIGERANT DRYER

C1888

Loading...

Loading...