Page 138 ST 700 SmartLine Pressure Transmitters User’s Manual Revision 13

12.6.1 Piping Arrangements

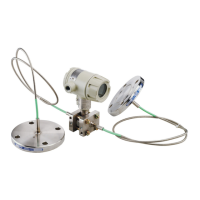

Piping arrangements vary depending upon process measurement requirements and the transmitter

model. For example, a differential pressure transmitter comes with double-ended process heads with

¼-inch NPT connections, which can be modified to accept ½-inch NPT through optional flange

adapters. Gauge pressure transmitters are available with various connections for direct mounting to a

process pipe.

A ½-inch, schedule 80, steel pipe is commonly used for transmitter integration into a process system.

Many piping arrangements use a three-valve manifold to connect the process piping to the transmitter.

A manifold makes it easy to install and remove or re-zero a transmitter without interrupting the

process. A manifold also accommodates the installation of blow-down valves to clear debris from

pressure lines. Figure 52 represents a typical piping arrangement using a three-valve manifold and

blow-down lines for a differential pressure transmitter being used to measure flow.

Figure 52– ST 700 Basic Transmitter - Typical 3-Valve Manifold with

Blow-Down Piping

Loading...

Loading...