56 XLS140 Installation Manual Form Number 95-7673-3 P/N 51927:C 12/06/2005

Installation Wiring a Signaling Line Circuit (SLC)

3.15 Wiring a Signaling Line Circuit (SLC)

Overview

Communication between the control panel and intelligent and addressable initiating, monitor, and

control devices takes place through a Signaling Line Circuit (SLC). You can wire an SLC to meet

the requirements of NFPA Style 4, Style 6, or Style 7 circuits. This manual provides requirements

and performance details specific to this control panel; for installation information and general

information, refer to the SLC Wiring Manual.

Wiring

Maximum wiring distance of an SLC using 12 AWG (3.31 mm

2

) wire is 12,500 feet (3810 meters)

total twisted-pair for Style 4, Style 6 and Style 7 circuits.

Capacity

The XLS140 provides one (1) SLC, with a total capacity of 318 intelligent/addressable devices:

• 01-159 intelligent detectors

• 01-159 monitor and control modules

An optional expander board provides one (1) additional SLC, with the same capacity.

Installation

This control panel supports one or two SLC loops; a second SLC loop is obtained by installing an

LEM-320 module. SLC loop #1 connects to TB16 on the control panel; SLC loop #2 connects to

TB1 on the LEM-320. For details on designing, installing and configuring SLC loops, see the SLC

Wiring Manual.

B+ A+ B- A- B+ A+ B- A-

T-Tapping is not allowed

on a four-wire SLC.

SLC B (output loop)

SLC A (loop return)

SLC B SLC A

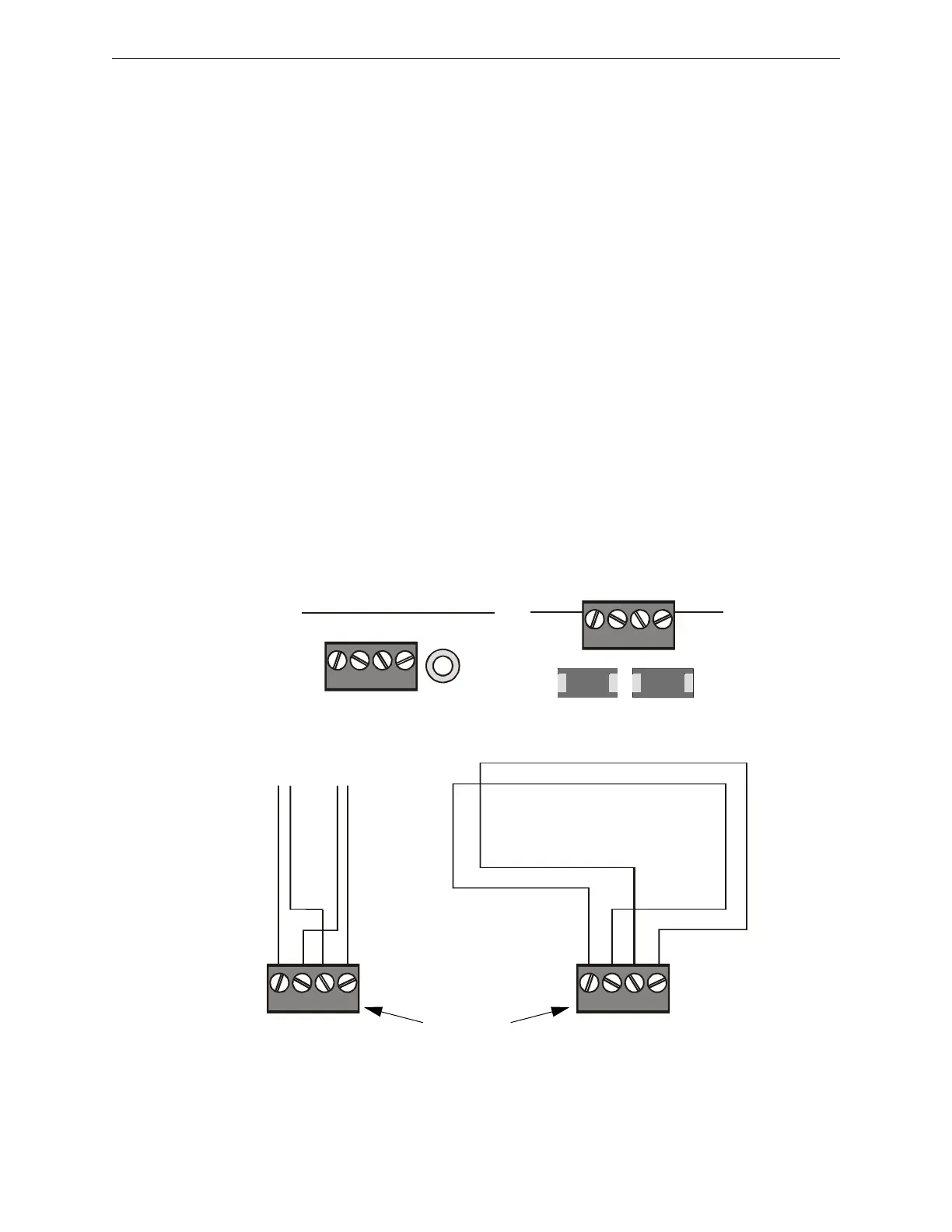

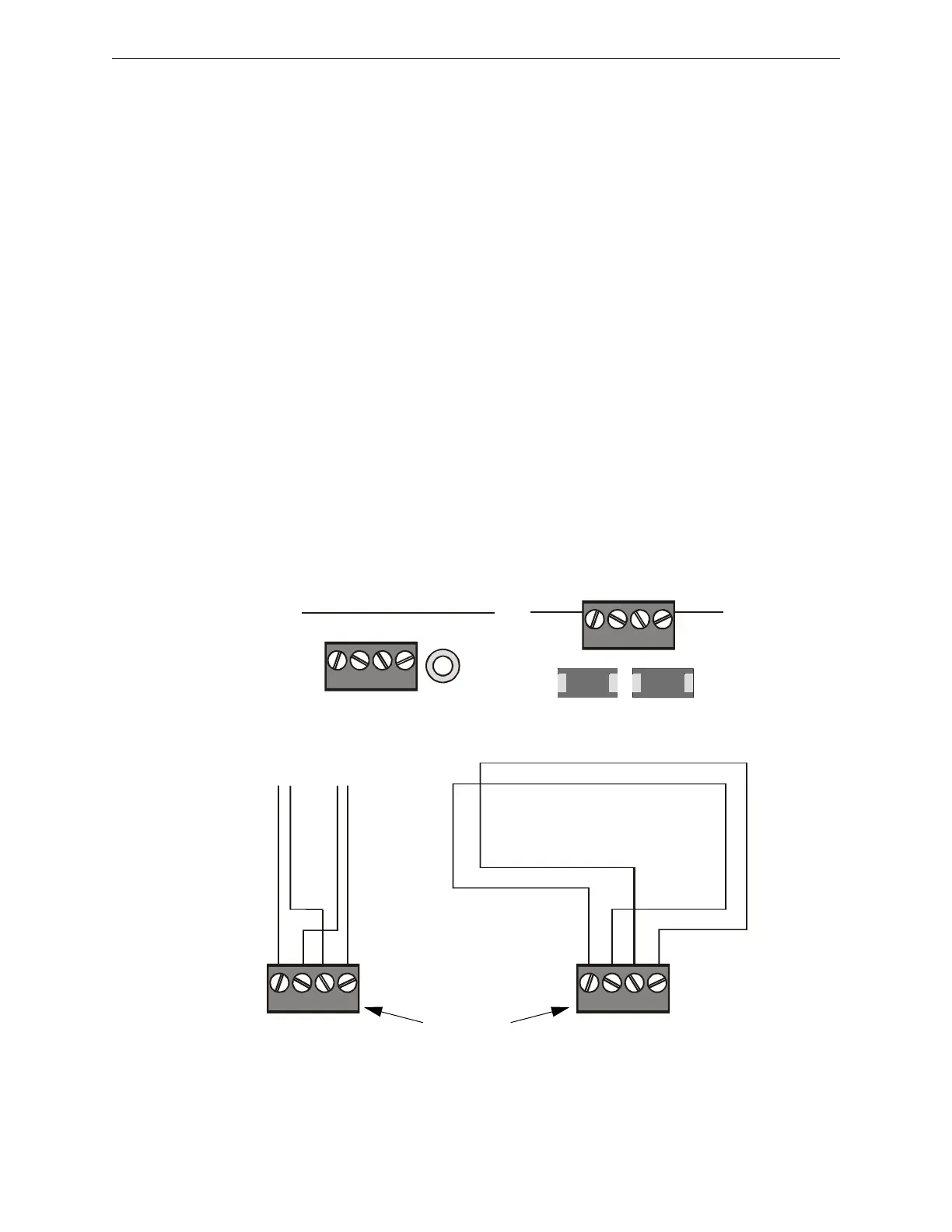

Style 4 SLC Loops Style 6 SLC Loops

TB1

B+ A+ B- A-

SLC1

B+ A+ B- A-

TB16

SLC Loop #2 Connections

on Loop Expander Module

SLC Loop #1 Connections

on FACP’s main circuit board

Use either

SLC Loop #1

or SLC Loop #2

nfs640-slcloops.cdr, nfs640-slc-tb.cdr, LEM320-slc-tb.cdr

Figure 3.30 SLC Loop Connections and Wiring

Loading...

Loading...