MEP S.p.A.

10--8 Use and maintenance manual DM 8

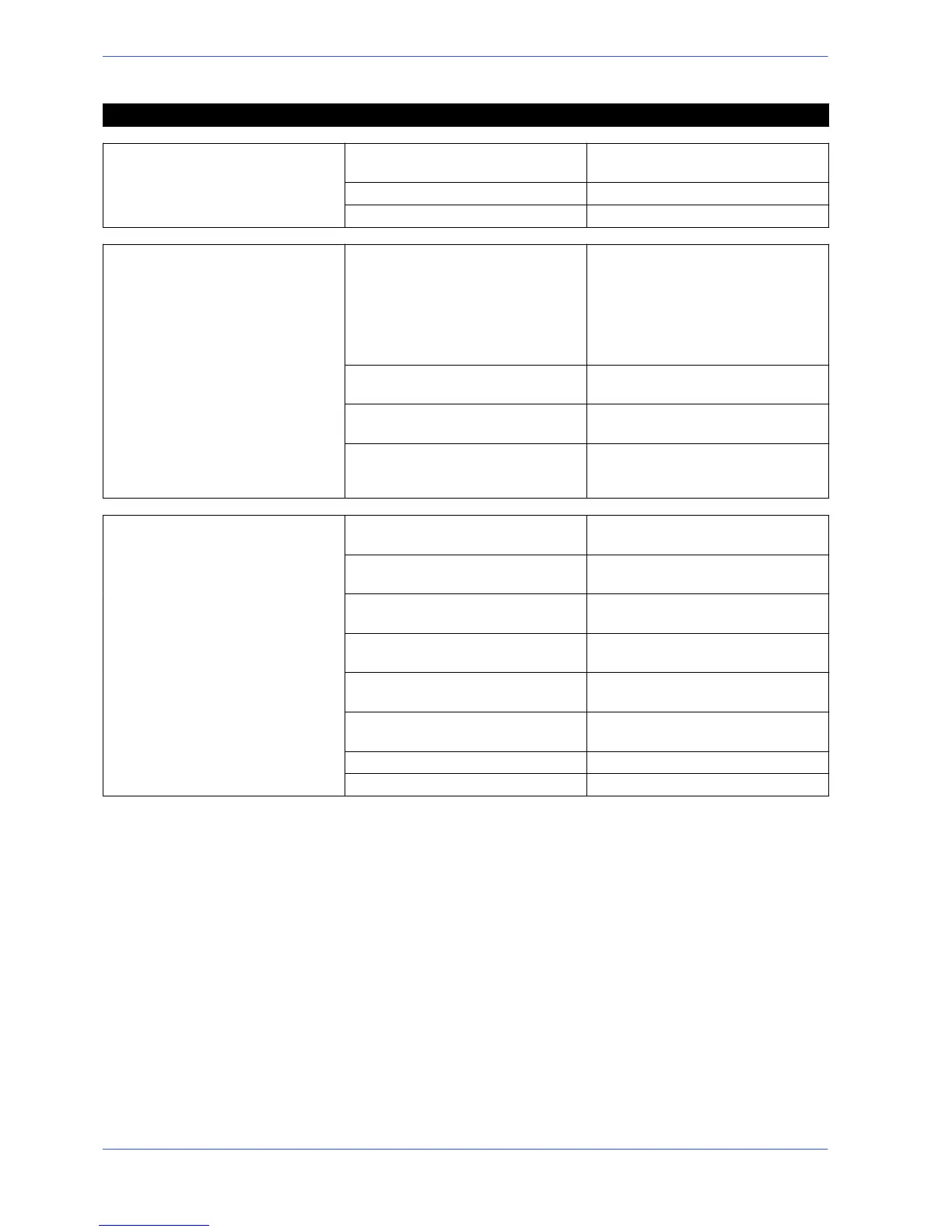

PROBLEM PROBABLE CAUSE SOLUTION

The pressure gauge does not gi-

ve blade tension pressure

' Oil level .Top up oil level in blade tensioner

cylinder

' Blocked connection .Check for blockages

' Broken .If damaged, replace

Vice does not close or does not

open (MA version)

' Pneumatic cylinder .Check that the cylinder gaskets are

airtight by removing the pipe (from

quick fit c onnection) where there is

no pressurised air, and checking if

air is escaping from the connection.

If air is escaping, replace the gas-

kets or the whole cylinder unit.

' VM: Vice valve .Check that the valve is functioning

properly; if necessary replace.

' Supply hose .Check that the pipe is not kinked or

blocked. Remove blockage

' Air treatment unit .Check that the air treatment group is

supplying the pressure shown on the

gauge.

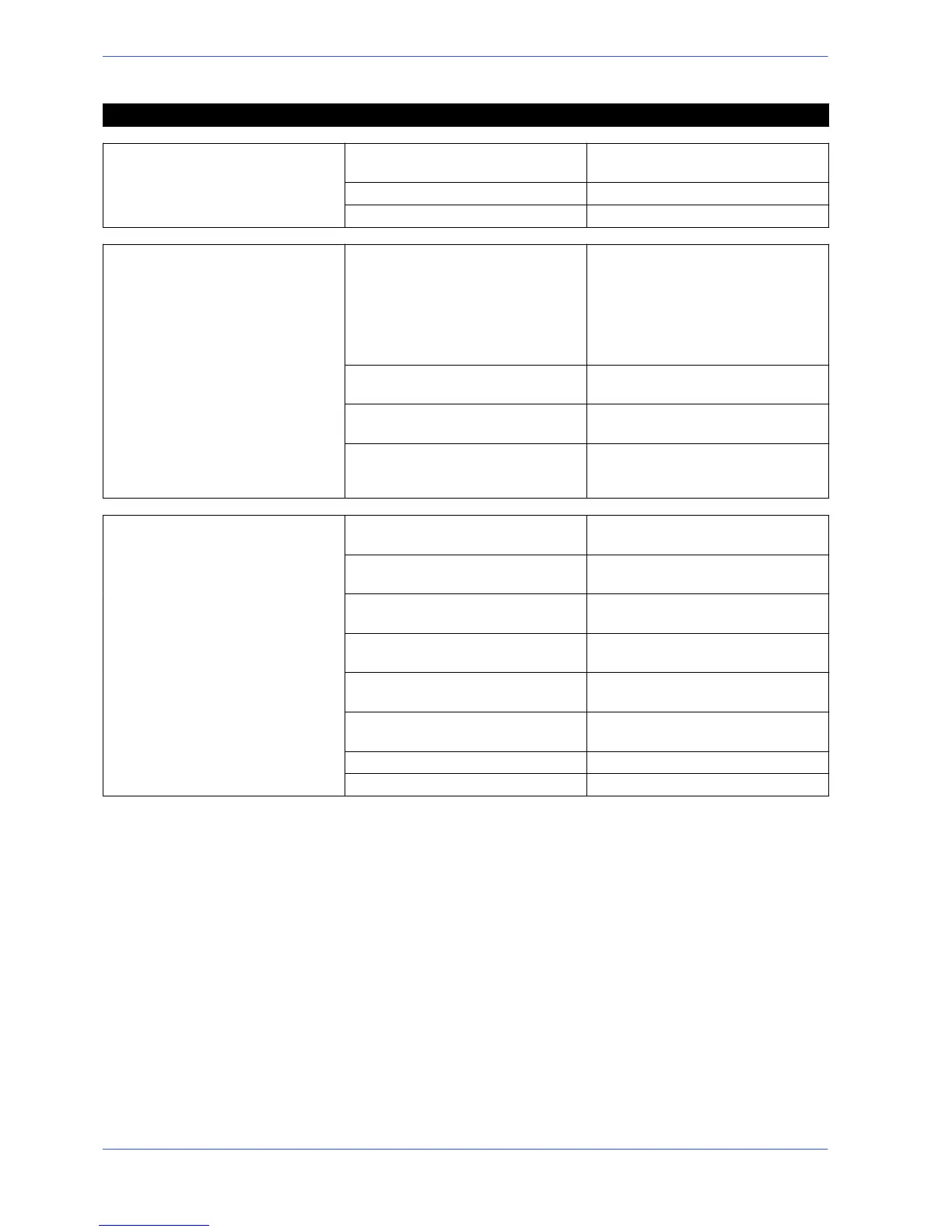

The CCS optional is not working

' Relay .Check that it is correctly supplied

and not burnt out

' Selector switch .Check connections. Replace if de-

fective

' Lock valve .Check for impurities preventing cor-

rect functioning. Replace if defective

' Regulator .Check that input and output pipes

are free of kinks and obstructions

' Spring .Check that the spring is correctly

tensioned

' Cylinder .Check that hydraulic circuit oil level

is sufficient

' Limiter .Check connections and functioning

' Head control lever microswitch .Check connections and functioning

Loading...

Loading...