Preventive maintenance

84 811390 Operator Manual DynaMAX 550P/560P/575P Waterjet Pump

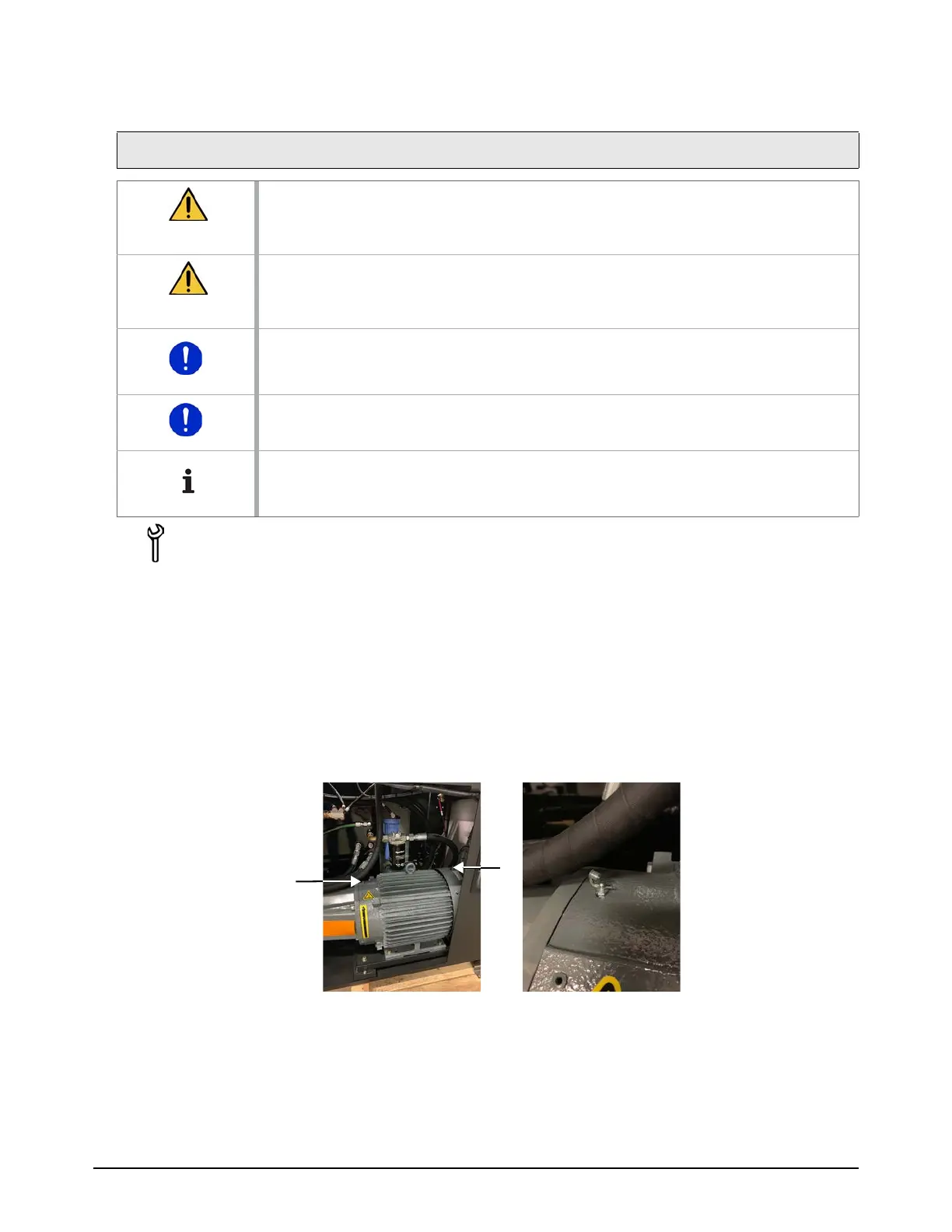

Lubricate the primary motor bearings

Parts, tools, and materials

Do this task when the pump is running.

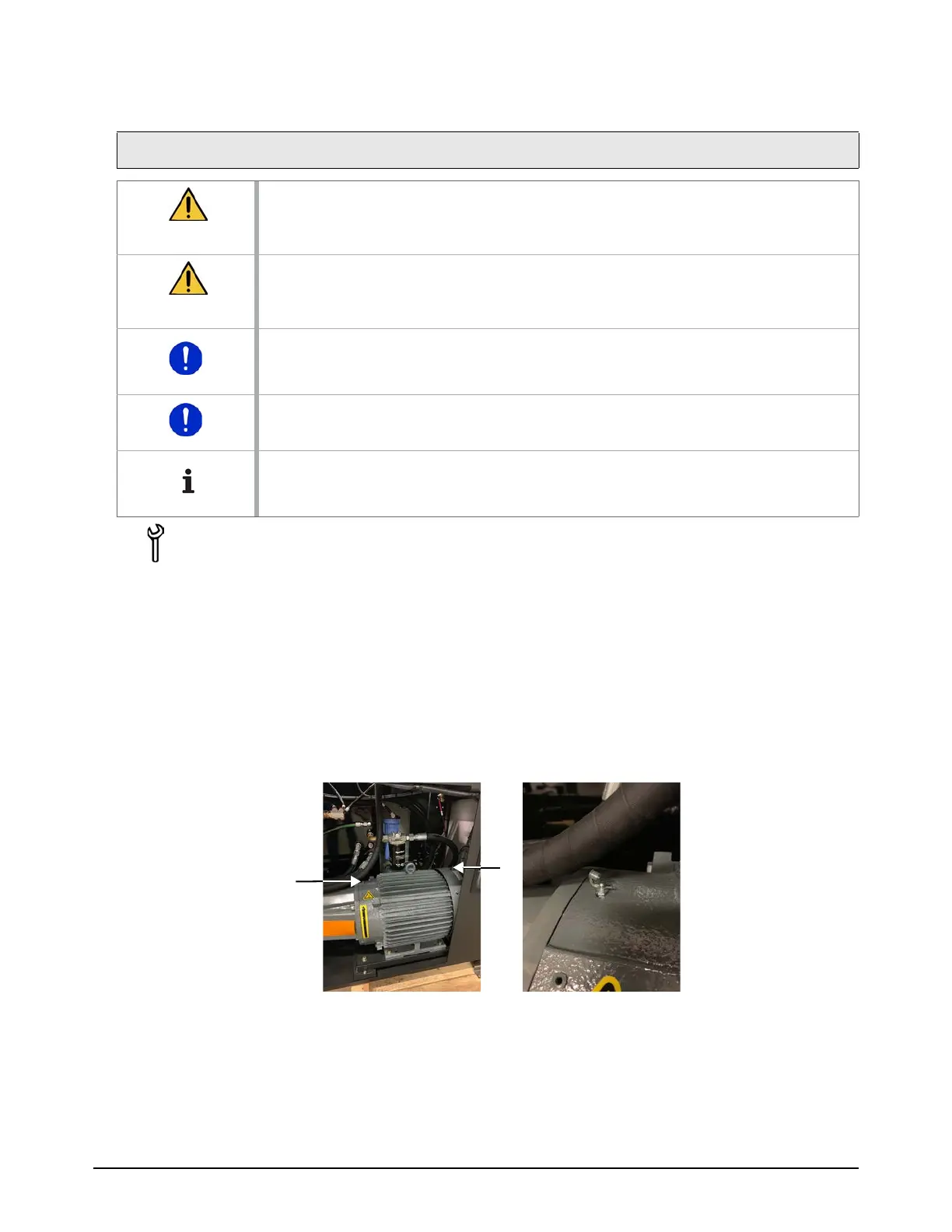

1. Remove the grease fitting cap from the motor.

2. Make sure the grease fittings are clean.

Do this every 6,000 hours.

CAUTION

Correct lubrication is important for motor performance.

Use the correct types and amounts of grease and oil.

CAUTION

the bearing can overheat if too much or not enough grease is used to lubricate the

bearing.

Use the postmaintenance start procedure after working on the primary motor. Refer to

Postmaintenance start procedure on page 131.

Do this procedure on both ends of the motor.

Most handheld pump grease have an output of 1.25 grams of grease per pump. Check

the manufacture of the grease gun.

Low-pressure handheld grease gun

Electric-motor bearing grease, NLGI grade 2

Clean towels

Recommended greases

Exxon Polyrex™ EM

Motors are lubricated with this grease at the

factory

Loading...

Loading...