Preventive maintenance

88 811390 Operator Manual DynaMAX 550P/560P/575P Waterjet Pump

Replace the Seal Maintenance Indicator tubes

The inner surfaces of the SMI tubes become dirty over time. Dirty tubes can cause a fluid monitoring

sensor error.

Parts, tools, and materials

Do this task when the pump is off.

1. Do steps 1 and 2 on page 87 to remove the tubes.

2. Do steps 5 and 6 on page 87 to install the new tubes.

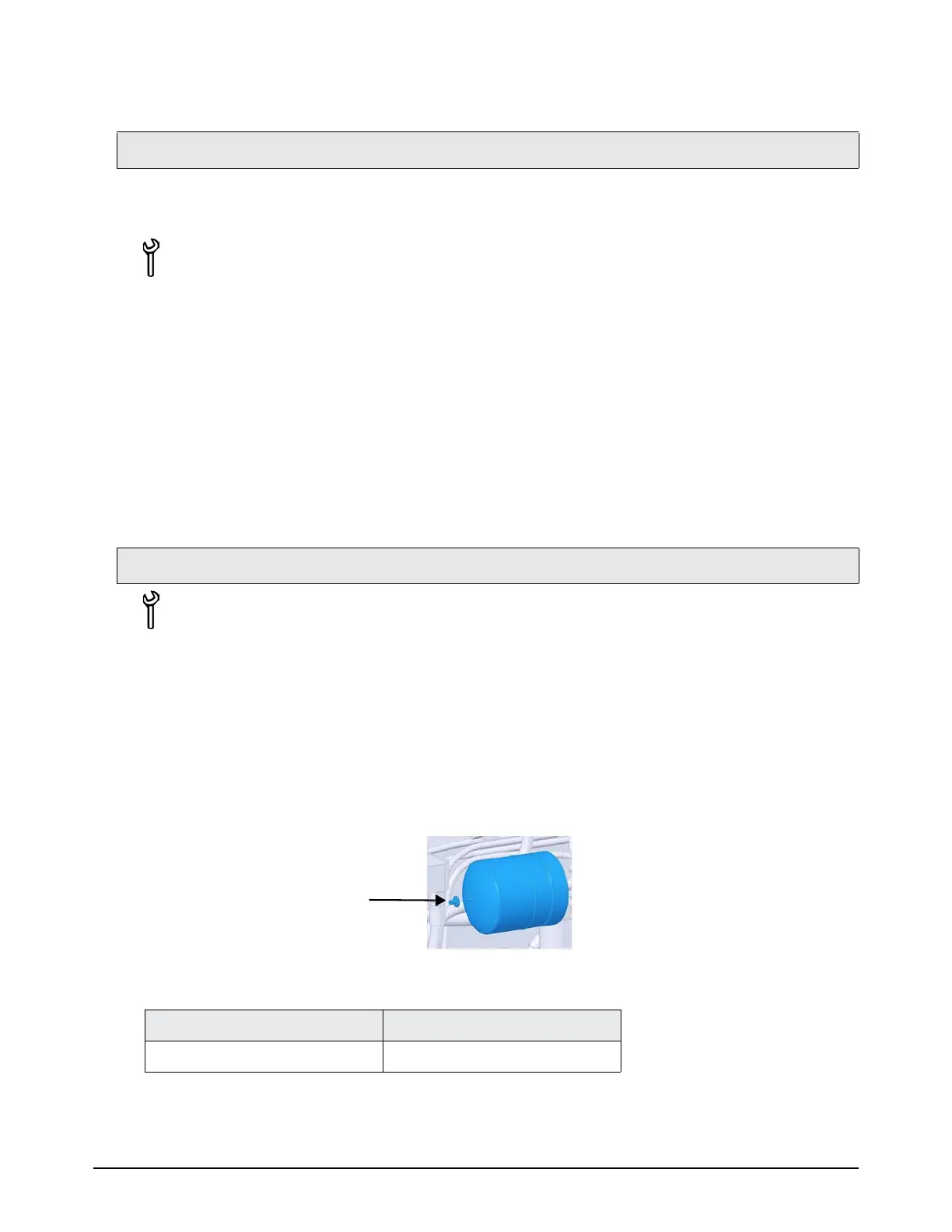

Measure the air pressure in the water accumulator tank

Parts, tools, and materials

Do this task when the pump is off.

1. Make sure that the water pressure gauges show 0.0 bar (0 psi).

2. Remove the valve stem cap from the water accumulator tank.

3. Use an air pressure gauge to measure the pressure in the tank.

4. Add compressed air to increase the pressure in the tank. To reduce pressure in the tank, push

on the valve stem to release air.

Do this every 1,500 hours.

Refer to Seal Maintenance Indicator™ (SMI) assembly on

page 144.

Do this every 500 hours.

Air pressure gauge (Schrader valve)

Compressed air source

Pump Category Optimal pressure

DynaMAX 550P-560P-575P 3.5 bar (50 psi)

Loading...

Loading...