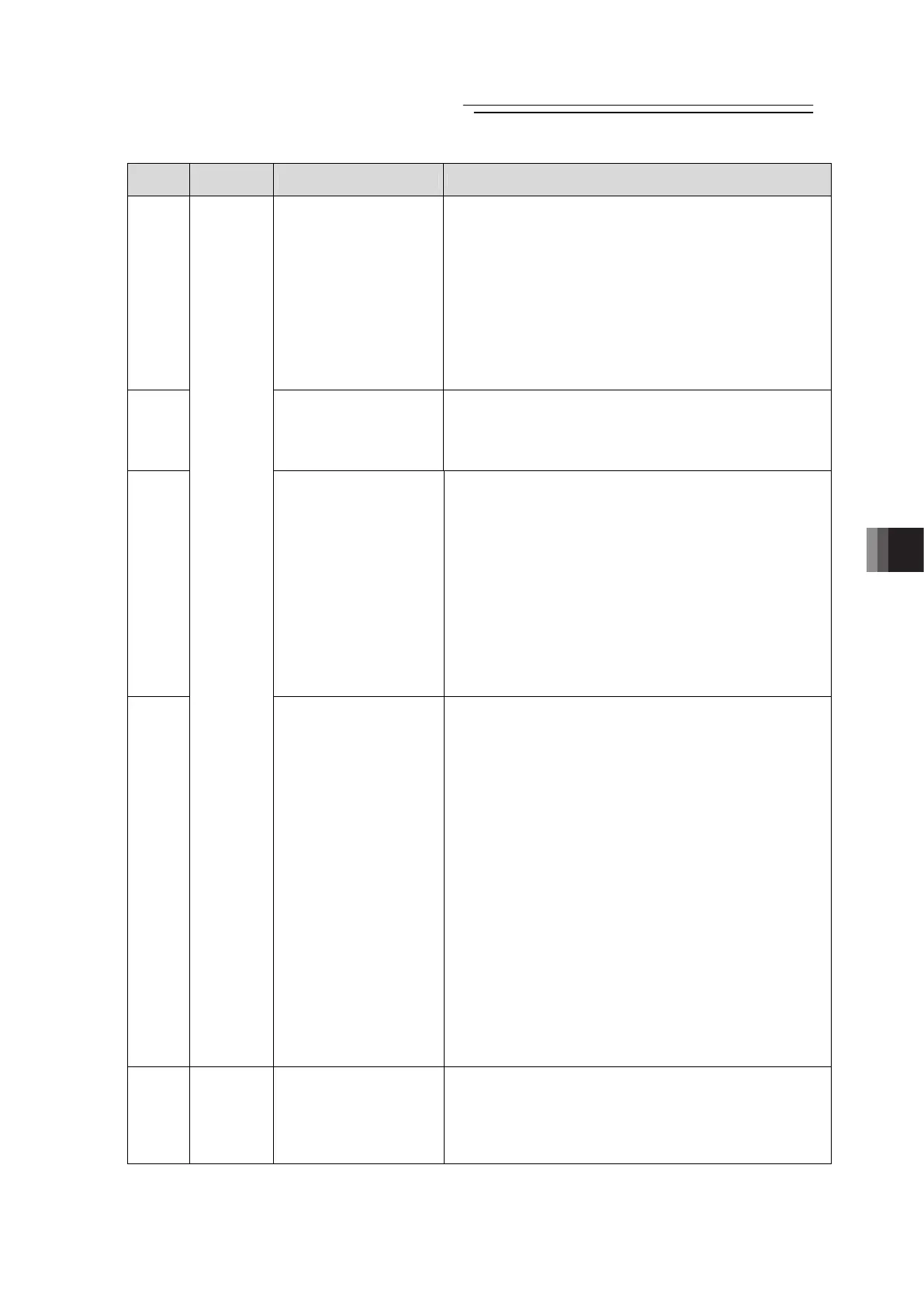

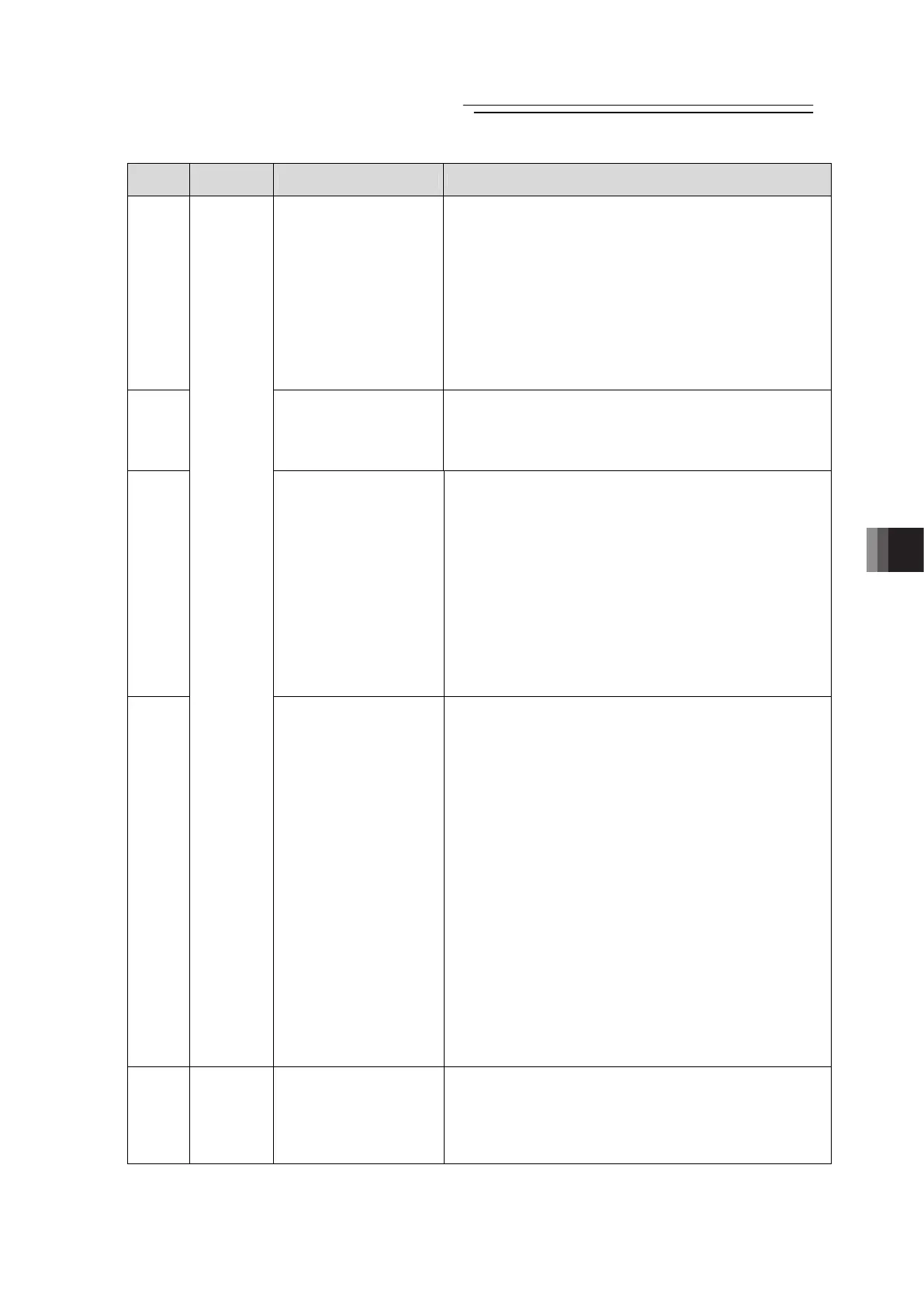

Chapter 9 Troubleshooting

POWER CON

PCON-CB/LC

227

Alarm

Code

Alarm Level Alarm Name Cause/Treatment

0BA Home sensor

non-detection

Cause : This indicates that the home-return operation of

the actuator equipped with origin sensor (option

except rotary actuator) is not completed in

normal condition.

1) Work is interfering with peripheral equipment

in the middle of home return.

2) Large slide resistance of the actuator itself

3) Installation failure, breakdown or

disconnection of the home sensor

Treatment : In the case that the work does not interfere with

anything, the cause 2) or 3) is supposed. In such

case, please contact IAI.

0BE Home return timeout Cause : Home return does not complete after elapse of a

certain period after the start of home return.

Treatment : This error does not occur in normal operation.

The combination of the controller and actuator

may be incorrect. Please contact IAI.

0C0 Actual speed excessive Cause : This indicates the number of motor rotation

exceeded the number of allowable rotation.

1) The slide resistance of the actuator is locally

high.

2) The load is increased too much due to a

external force.

With the reasons above, it can be considered a

sudden speed increase has occurred before

detecting the servo error.

Treatment : Even though this would not occur in normal

operation, check if there is any abnormality in the

parts assembly condition. Also check if there is a

possibility that an external force may be applied

in the direction of the actuator movement.

0C1

Operation

release

Servo error Cause : It indicates 2 seconds has passed without

making a move since a move command was

received.

1) Connection error or wire breakage of

motor/encoder cables.

2) Brake is not released (when equipped with a

brake).

3) Load to the motor is high due to external

force.

4) The resistance in the actuator sliding

operation is large.

Treatment : 1) Check for the motor/encoder cable wiring

condition.

2) Supply 24V DC 150mA to the BKRLS terminal

on the power supply connector and if you can

see an improvement, it is considered the

controller failure. Please contact IAI.

3) Confirm that there is no error in the

mechanical part assembly condition.

4) If the loaded weight is within the allowable

range, turn the power OFF and check the

resistance in sliding operation by moving the

slider with hand.

0C8

Cold start

Overcurrent Cause : The output current in the power circuit section is

increased abnormally.

Treatment : This alarm will not be generated in normal

operation. It can be considered as the insulation

degradation of the motor winding or malfunction

of the controller. Please contact IAI.

Loading...

Loading...