RCP6 RoboCylinder

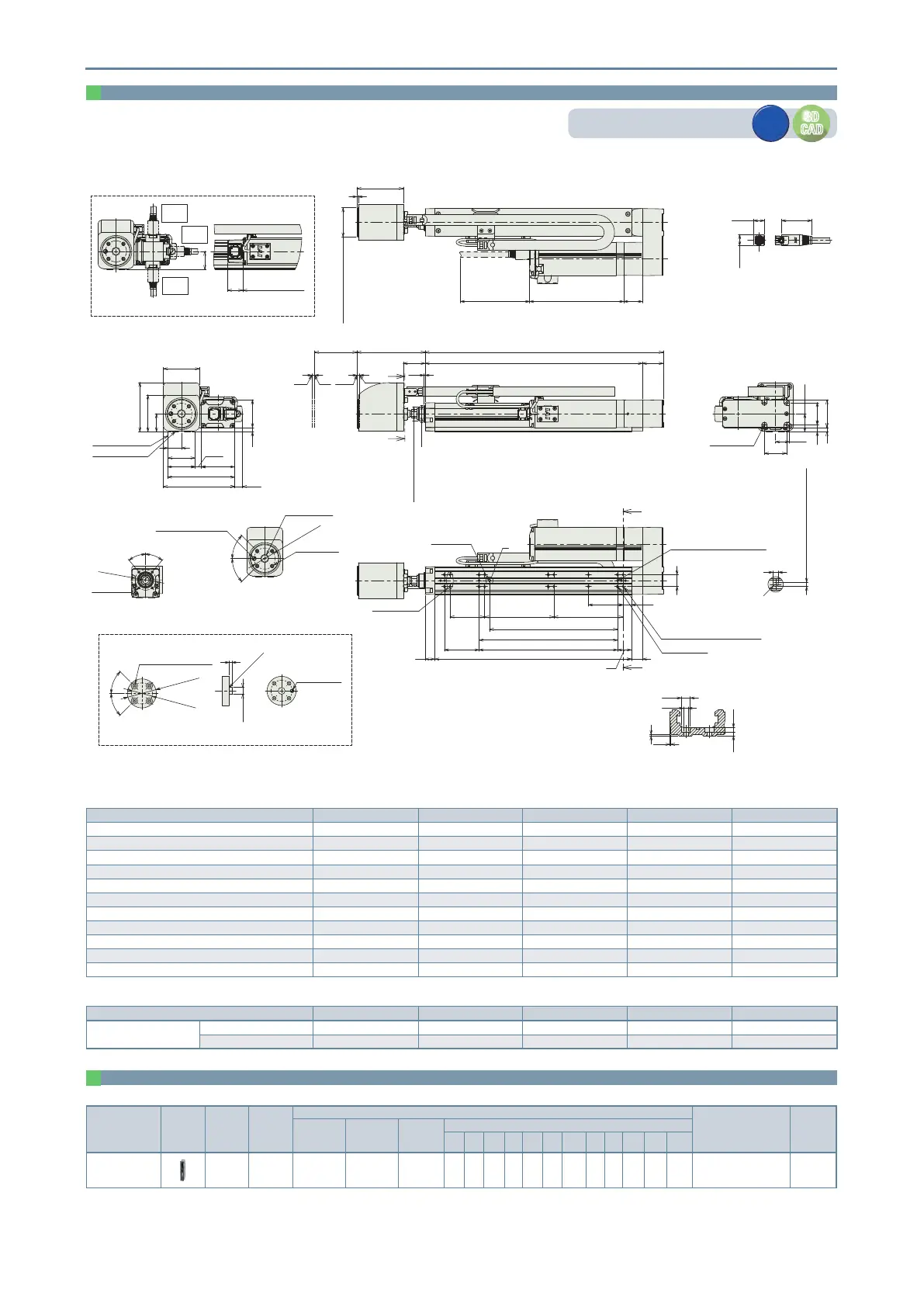

7 RCP6-RRA4R

*1 The 2 counterbored mounting holes shown in the gure cannot be used.

(Note) When returning to the home position, the rod will move to the M.E. Be careful of interference with surrounding objects.

ST: Stroke

M.E: Mechanical end

S.E: Stroke end

S

S

V

V

Load cell tip mounting jig reference size

4 4

ST

30

A

L

98.5

31.5

1.5

ø24h7

ø20 (rod outer diameter)

S.E.M.E.

Home

M.E.

01 23

32

40

6

4-M4 depth 9

(20)

(26)

39

40

97

(6)

40

48

(8.7)

52

71

103

26

19.5

(11)

53

Base mounting surface

Reference surface

(Dimension B range)

20

C

B 16

17

K (between ø3 hole - ø3 hole)

J (ø3 hole - oblong hole)

2-ø3H7 reamed, depth 4

(from base mounting surface)

E-M4 depth 6

14

H-

ø

3.4 through,

6.5 deep counterbored,

depth 3.5 (from the opposite side)

G×100P

1250

50 F

D×100P

Oblong hole

*1 Unavailable

P

40°

40°

P.C.D.30

4-M4 depth 8

Cross section of S-S

45°

45°

ø5H7 reamed, depth 5

ø10H7 depth 5

P.C.D.30.5

4-M5 depth 8

Jig mounting dimensions details

(equidistant)

4

Depth 4 from base seating surface

(R)

Detailed view of P

Base oblong hole details

(43.3)

Cable connection

(16.2)

(15.6)

Cable exit direction (option)

22

135 (w/o brake)

179 (with brake)

P.C.D.30.5

ø42 or more

45°

45°

4-ø5.5 through,

ø9.5 deep counterbored,

depth 5.5

(equidistant)

4

ø10h7

R0.5 or less

ø5H7 reamed

3

+0.010

0

Must be

100 or more

2

ø42 (load cell outer diameter)

136 (w/o brake)

180 (with brake)

27

67

26

Cable exit direction (option)

CJB

bottom

CJO

outside

CJT

top

0.5

1

2.5 3.5

ø3.4

ø6.5

Cross section V-V

Details of base mounting counterbored holes

Dimensions by stroke

Stroke 110 160 210 260 310

L 244 294 344 394 444

A 214 264 314 364 414

B 184 234 284 334 384

C 50 100 50 100 50

D 1 1 2 2 3

E 6 6 8 8 10

F 100 50 100 50 100

G 0 1 1 2 2

H 8 10 10 12 12

J 85 85 185 185 285

K 100 100 200 200 300

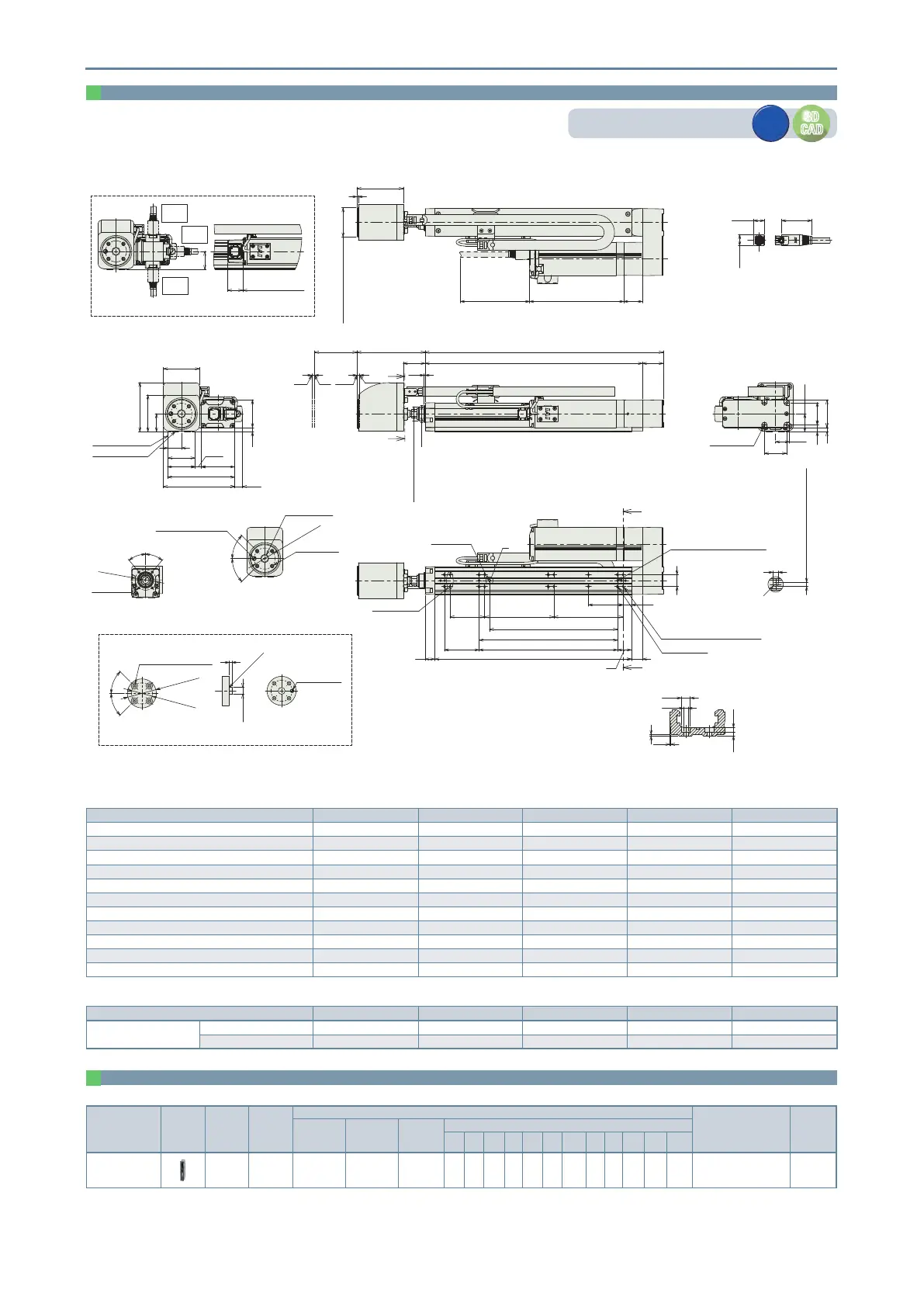

Mass by stroke

Stroke 110 160 210 260 310

Mass

(kg)

Without brake 2.2 2.3 2.4 2.6 2.7

With brake 2.4 2.5 2.7 2.8 2.9

Dimensions

CAD drawings can be downloaded from our website.

www.robocylinder.de

3D

CAD

3D

CAD

2D

CAD

2D

CAD

Applicable Controllers

The actuators on this page can be operated by the controllers indicated below. Please select the type depending on your intended use.

Name

External

view

Maximum

number of

connectable

axes

Power

supply

voltage

Control method

Maximum number

of positioning points

Reference

page

Positioner

Pulse-train

Program

Network (*Option)

DV CC CIE PR CN

ML

ML3

EC EP

PRT

SSN

ECM

PCON-CBP/

CGBP

1 24VDC

*Option

- -

---

- -

512

(768 for network

spec.)

18

(Note) Please refer to P. 19 for information on network abbreviation codes such as DV and CC.

Loading...

Loading...