Rev AA Theory of Printing 2-3

Theory of Printing

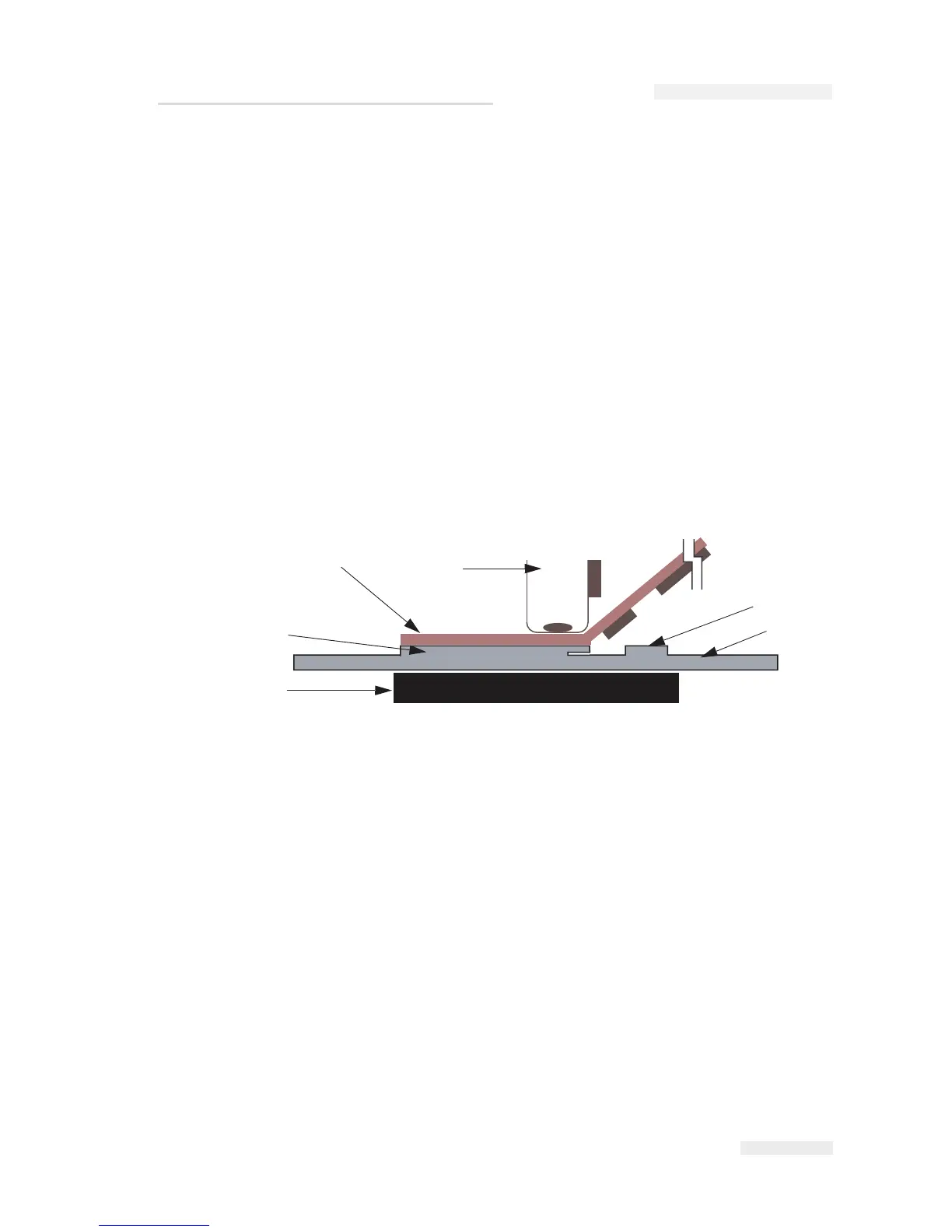

The information on how the thermal transfer printer works is as follows

(Figure 2-1):

• The printhead contains miniature heating

elements under a glass

coat

ing (300 dpi - 12 dots/min)

• A carrier ribbon, with ink bonded to one side is used as

the printing

media

•

The printhead presses against the thermal transfer ribbon with

the ink

side of ribbon

in contact with the substrate, creating an image.

• Print elements heat small areas of the ribbon and this transfers th

e ink

to

the target substrate

• The printhead and the substrate move relative to each other

• T

he print elements are programmable and controlled to create an

image

Intermittent Motion Printing

Intermittent motion printing (Figure 2-2 on page 2-4) is the concept used

for printing on stationary packaging films in packaging equipment that

has a start/stop action each time a product is packed. Such applications

can be found in intermittent Vertical Form Fill Seal (VFFS) or bagging

machines, and self adhesive label applicators.

Intermittent motion printing has the following features:

• The substrate is stationary

1

2

3

4

5

6

1. Ribbon Transferred Carbon

2. Substr

ate

3. Platten Rubber

4. In

k

5. B

ase Film

6. T

hermal Printhead

Figure 2-1: Printing Process

ICE Pegasus Service Manual

Loading...

Loading...