Intel Thermal/Mechanical Reference Design Information

Thermal and Mechanical Design Guidelines 45

5.2.1.2 Shock Test Procedure

Recommended performance requirement for a motherboard:

•

Quantity: 3 drops for + and - directions in each of 3 perpendicular axes (i.e.,

total 18 drops).

•

Profile: 50 G trapezoidal waveform, 11 ms duration, 170 in/sec minimum

velocity change.

•

Setup: Mount sample board on test fixture.

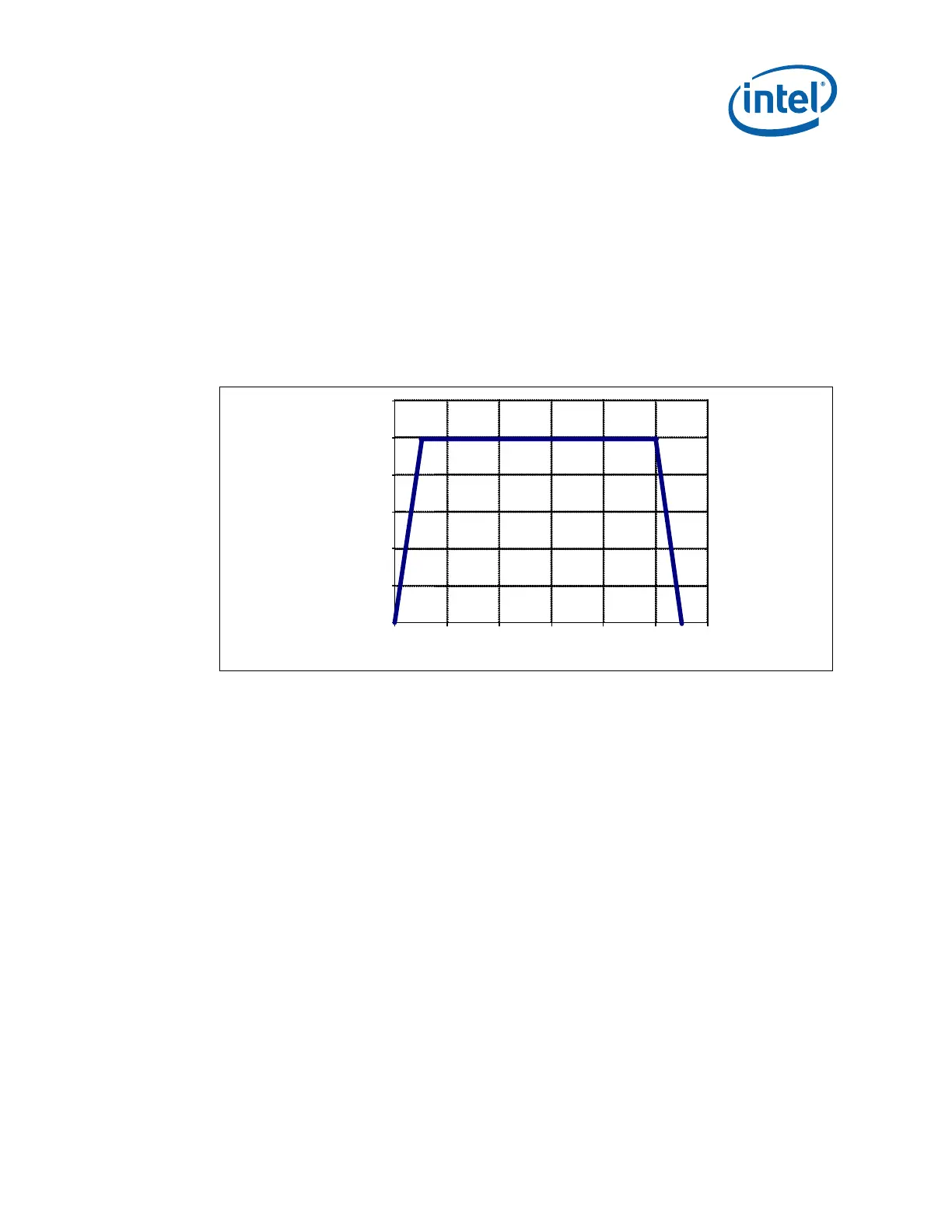

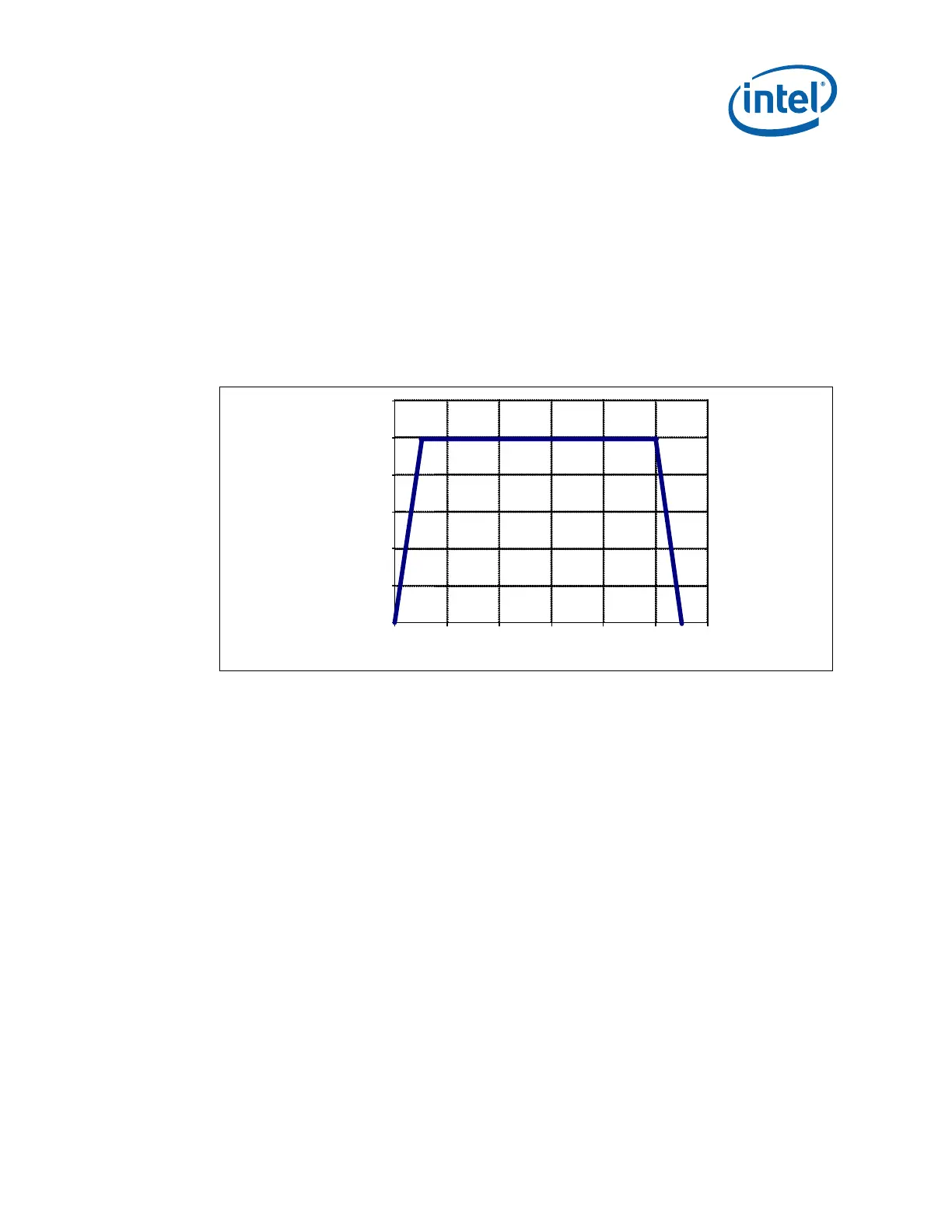

Figure 12. Shock Acceleration Curve

0

10

20

30

40

50

60

0

4 6

10 12

Time

milliseconds

A

c

c

e

l

e

r

a

t

i

o

n

(g)

5.2.1.2.1 Recommended Test Sequence

Each test sequence should start with components (i.e., motherboard, heatsink

assembly, etc.) that have never been previously submitted to any reliability testing.

The test sequence should always start with a visual inspection after assembly, and

BIOS/CPU/Memory test (refer to Section 5.2.3).

Prior to the mechanical shock & vibration test, the units under test should be

preconditioned for 72 hours at 45 ºC. The pre-conditioning is intended to present the

system burn-in and shipping/storage environment stress.

The stress test should be followed by a visual inspection and then BIOS/CPU/Memory

test.

Loading...

Loading...