Case Temperature Reference Metrology

Thermal and Mechanical Design Guidelines 81

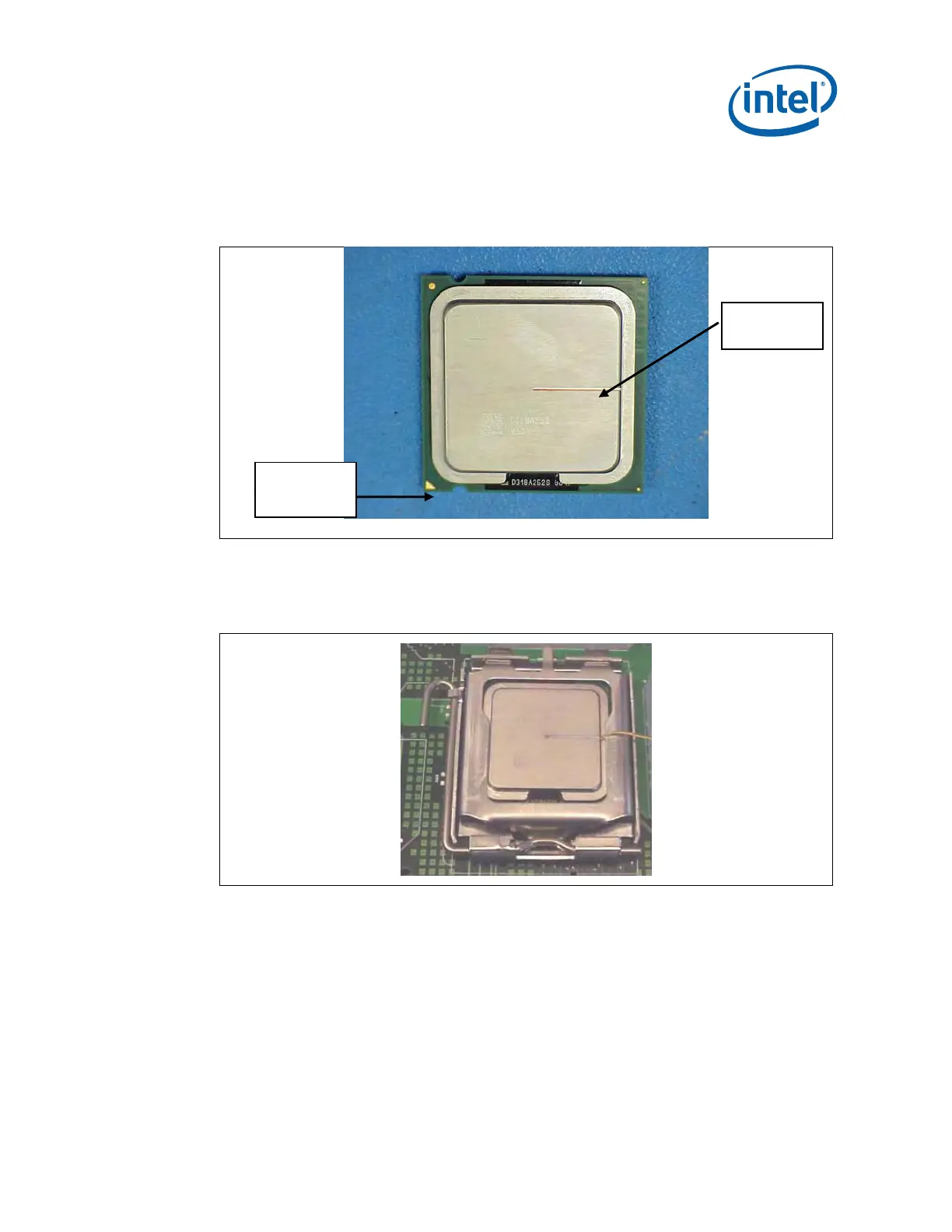

The orientation of the groove relative to the package pin 1 indicator (gold triangle in

one corner of the package) is shown.

Figure 33 for the 775-Land LGA package IHS.

Figure 33. IHS Groove on the 775-LAND LGA Package

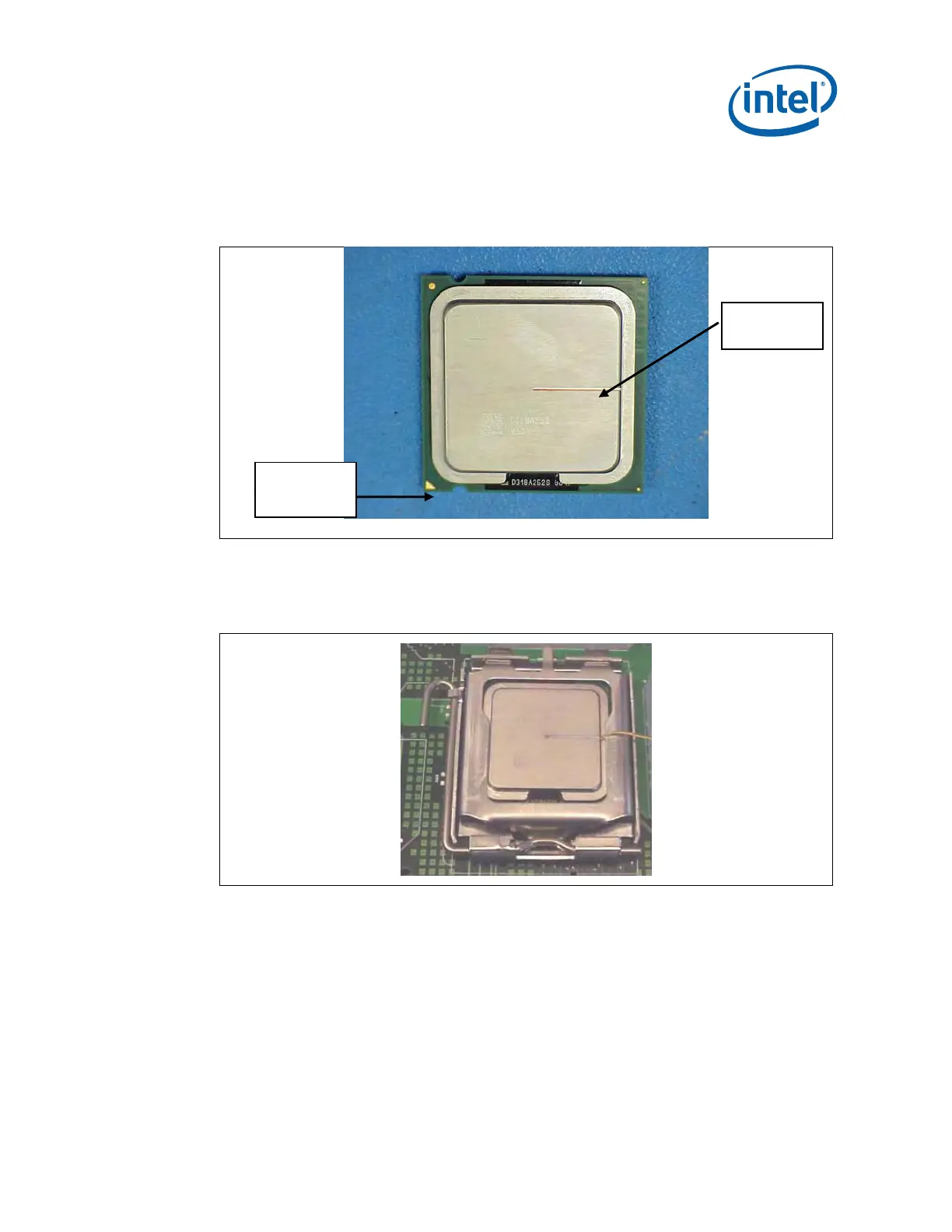

When the processor is installed in the LGA775 socket, the groove is perpendicular to

the socket load lever, and on the opposite side of the lever, as shown

Figure 34.

Figure 34. IHS Groove Orientation Relative to the LGA775 Socket

Select a machine shop that is capable of holding drawing specified tolerances. IHS

groove geometry is critical for repeatable placement of the thermocouple bead,

ensuring precise thermal measurements. The specified dimensions minimize the

impact of the groove on the IHS under the socket load. A larger groove may cause the

IHS to warp under the socket load such that it does not represent the performance of

an ungrooved IHS on production packages.

Inspect parts for compliance to specifications before accepting from machine shop.

Pin1

indicator

IHS Groove

Loading...

Loading...