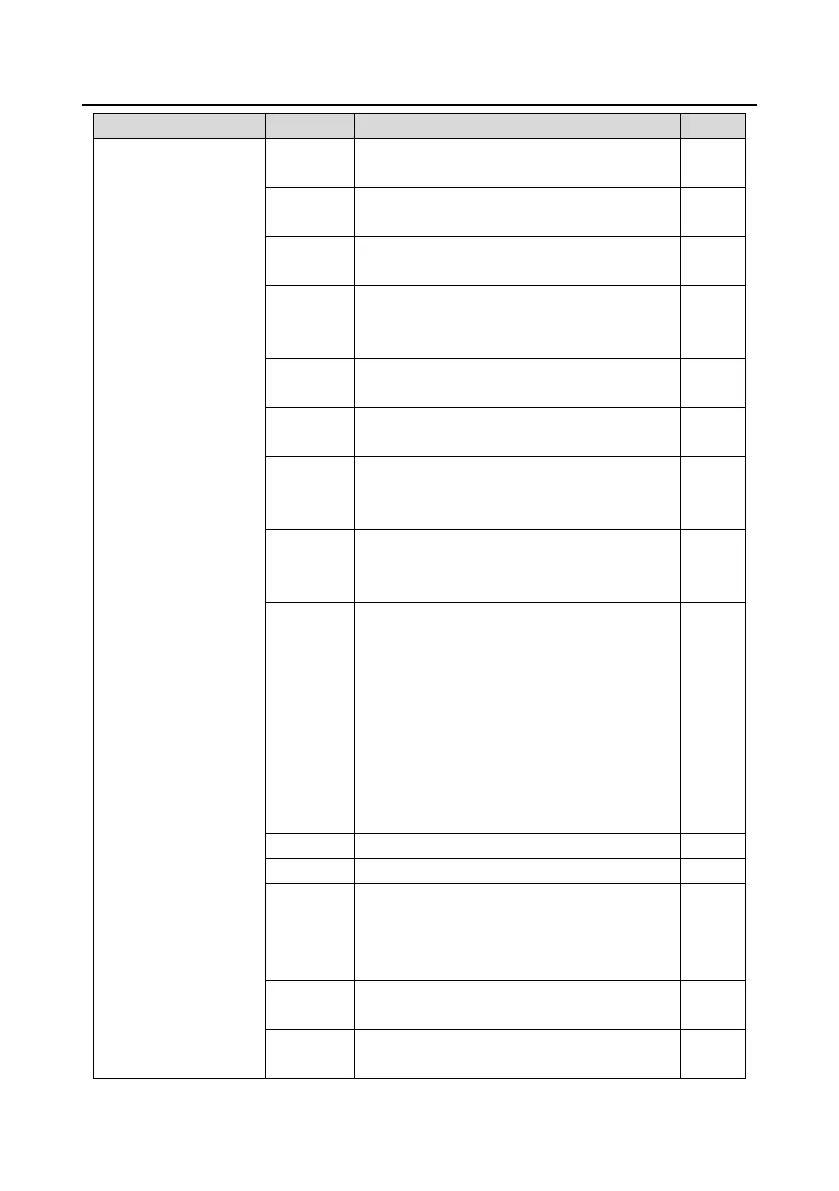

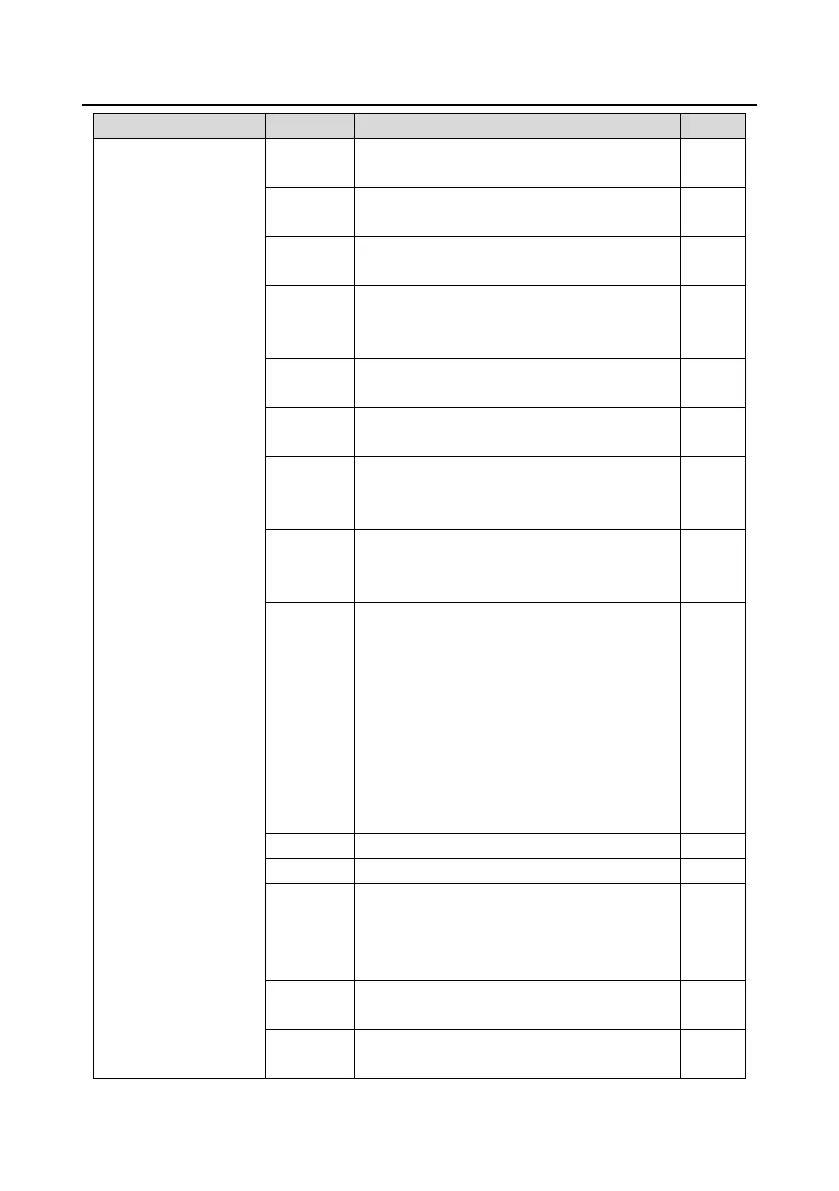

Goodrive300-21 integrated machine for air compressor Communication protocol

-102-

Communication-based

setting address

Communication-based frequency setting (0–

Fmax; unit: 0.01 Hz)

PID reference (0–1000, in which 1000

corresponds to 100.0%)

PID feedback (0–1000, in which 1000

corresponds to 100.0%)

Torque setting (-3000–3000, in which 1000

corresponds to 100.0% of the motor rated

current)

Upper limit setting of forward running frequency

(0–Fmax; unit: 0.01 Hz)

Upper limit setting of reverse running frequency

(0–Fmax; unit: 0.01Hz)

Upper limit of the electromotive torque (0–3000,

in which 1000 corresponds to 100.0% of the

motor rated current)

Braking torque upper limit. (0–3000, in which

1000 corresponds to 100.0% of the inverter

rated current)

Special CW

Bit0–1: = 00: Motor1 =01: Motor2

=10: Motor 3 =11: motor 4

Bit2: =1: Torque control =0: Speed control

Bit3=1 Clear electricity consumption data

=0: Keep electricity consumption data

Bit4=1 Enable pre-excitation =0: Disable

pre-excitation

Bit5=1 Enable DC braking =0: Disable DC

braking

Virtual input terminal command (0x000–0x1FF)

Virtual output terminal command (0x00–0x0F)

Voltage setting (used when V/F separation is

implemented)

(0–1000, 1000 corresponding to 100.0% of the

motor rated voltage)

AO setting 1 (-1000–+1000, in which 1000

corresponding to 100.0%)

AO setting 2 (-1000–+1000, in which 1000

corresponding to 100.0%)

Loading...

Loading...