Goodrive300-21 integrated machine for air compressor Installation guidance

-9-

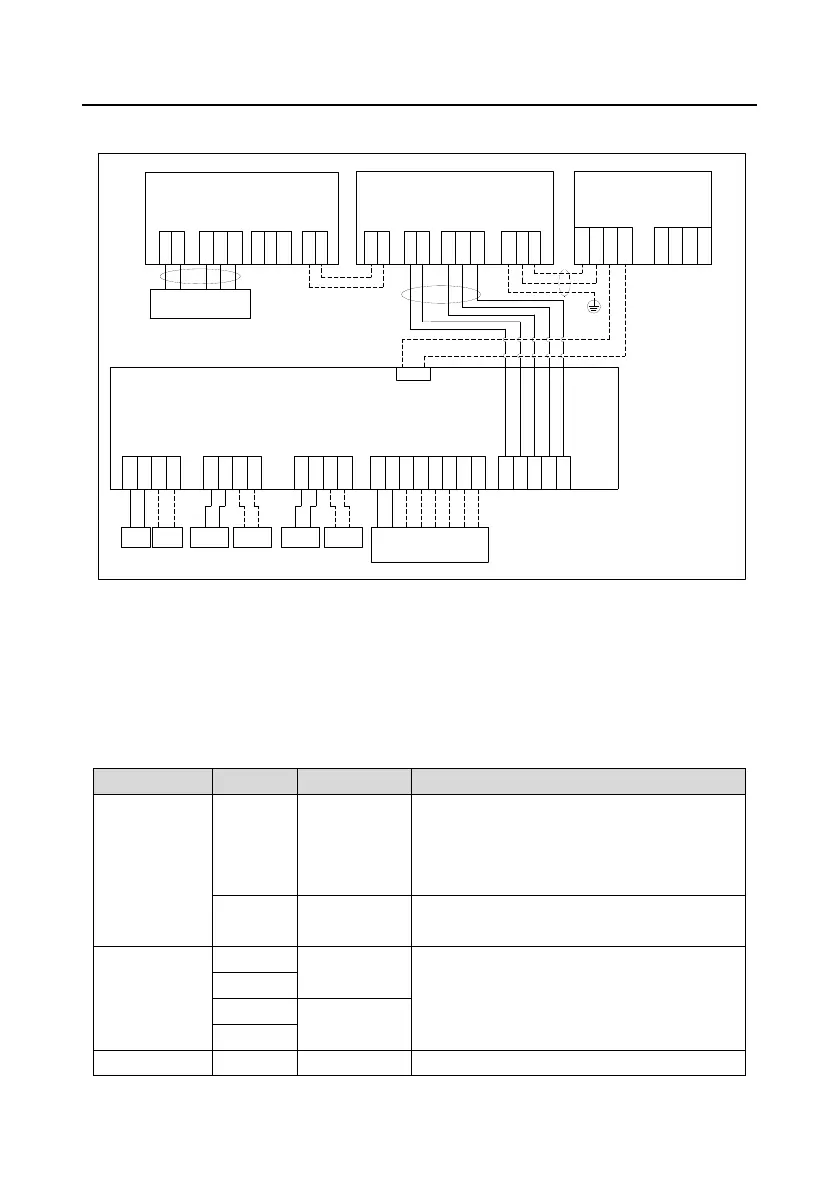

2.2.2 Wiring diagram of control circuit

TA1

TC1

TA2

TC2

P1+

P1-

P2+

P2-

PTA1

PTB1

PTA2

PTB2

S1

S2

S3

S4

S5

Y1

COM

Solenoid

valve

+24V

GND

485+

485-

PE\CGND

GD300-21 control board

+24V

GND

485A+

485A-

PE

485C+

485C-

HMIHMI

+24V

GND

485A+

485A-

PE

485C+

485C-

485B-

485B+

PE

RS485 joint control

Y1: Fault output signal

Oil gas temp.

Pressure sensor

interface

24V 4-20mA

PT100 temperature

sensor interface

Multi-function terminal

Output voltage

220/110VAC

coil

Contactor

coil

Exhaust

pressure

Auxiliary

pressure

S1:E-stop signal (NC)

S2-S5: Customized input

Auxiliary

temp.

+24V

GND

13

CN17

COM

485B-

485B+

PE

GD300-21

control board

RS485

J1

485+

485-

+24V

GND

485A-

GND

+5V

485A+

J2

(Optional)

Remote data collection terminal

Figure 2-7 Wiring diagram of control circuit

Note: The solid line represents the recommended wiring diagram which carries the least wiring for

ensuring system operation. The dotted line represents the wiring diagram used when discrepancy

occurred to the configuration of integrated machine.

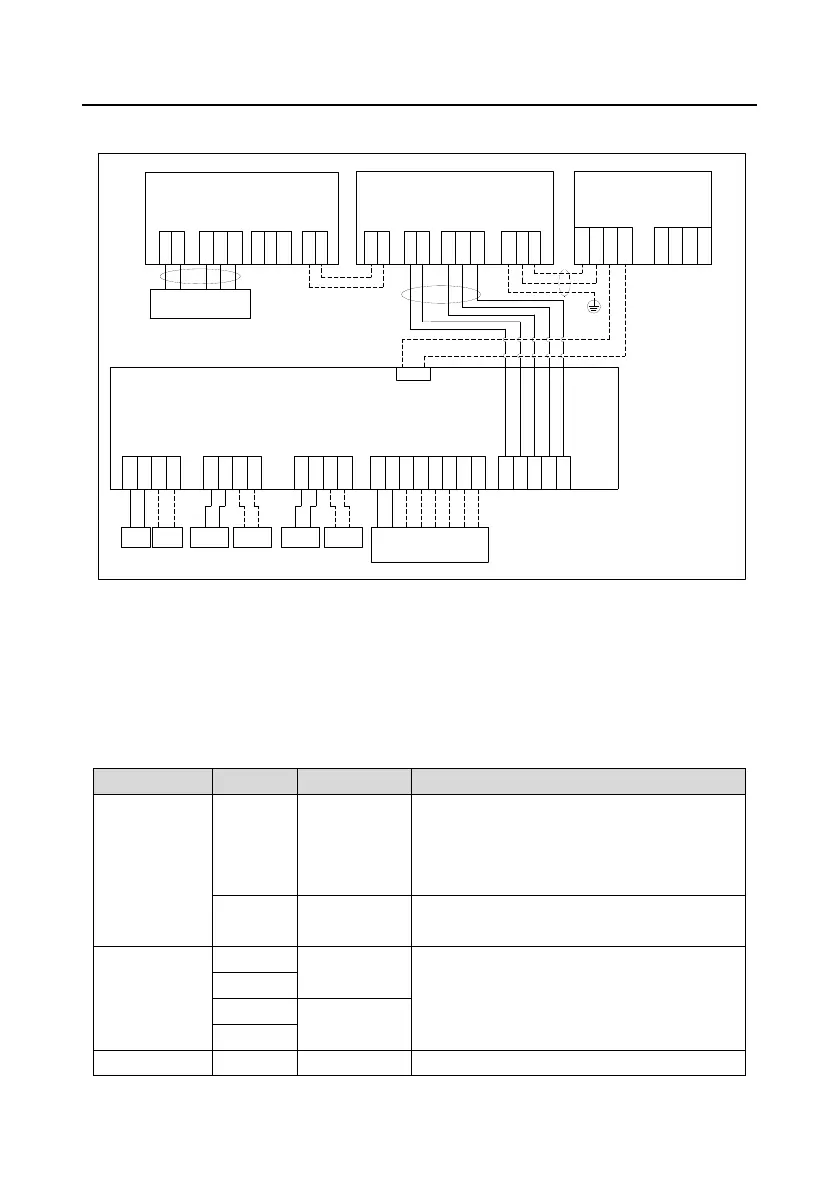

2.2.3 User terminal instruction of control circuit

Table 2-1 User terminal instruction of control circuit

Used to externally provide +24V±5% power

supply, max. output current: 1A

Used for powering up GPRS, touch screen

module

Reference ground of the +24V power supply

Temperature

analog signal 1

1. Resolution rate: 1°C

2. Range: -20°C–150°C

3. Detection precision: 3°C

Temperature

analog signal 2

1. Input range: Current and voltage is optional,

Loading...

Loading...