6

DAILY MCA2014 4x4 ‒ BODYBUILDER INSTRUCTIONS

ADBLUE AND SCRT SYSTEM

6.3 INSTRUCTIONS

– Printed 603.95.994 – 1 Ed. - Base 05/2015

● the SM and DM fittings must be handled with care;

● the SM and DM fastening screws must be tightened to the torque specified in the relevant assembly diagrams;

● the seal of the DM flange on the ATS side must be replaced each time the DM is disassembled (the seal may only be used

once);

● the “after-run” phase must not be interrupted using the battery manual switch or the ADR switch (the AdBlue pipes must

always be emptied to prevent any crystallization or damage from freezing);.

Materials

The AdBlue solution may be corrosive for ferrous steels and, in turn, may be contaminated by additives used for moulding plastic

materials. Therefore any parts of specific form may only be realized upon IVECO approval and only with the following materials:

● Molybdenum austenitic chromium-nickel steel in compliance with DIN EN 10088

● Polyethylene HD

● Polypropylene HD

● Polyfluoroethelene

● Polyvinylidene fluoride

● Perfluoroalkoxy

● Polyisobutylene

● Titanium

● Viton

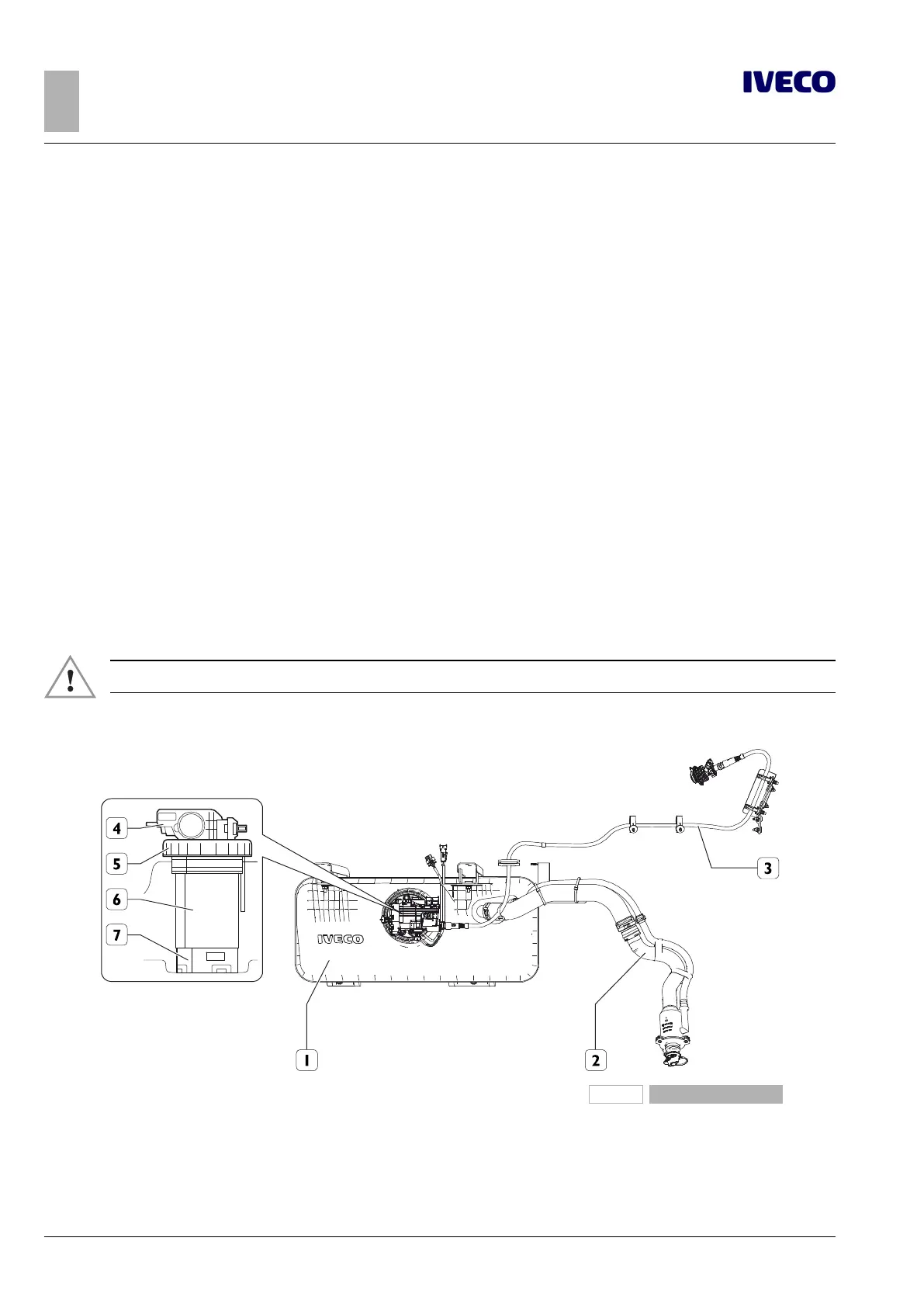

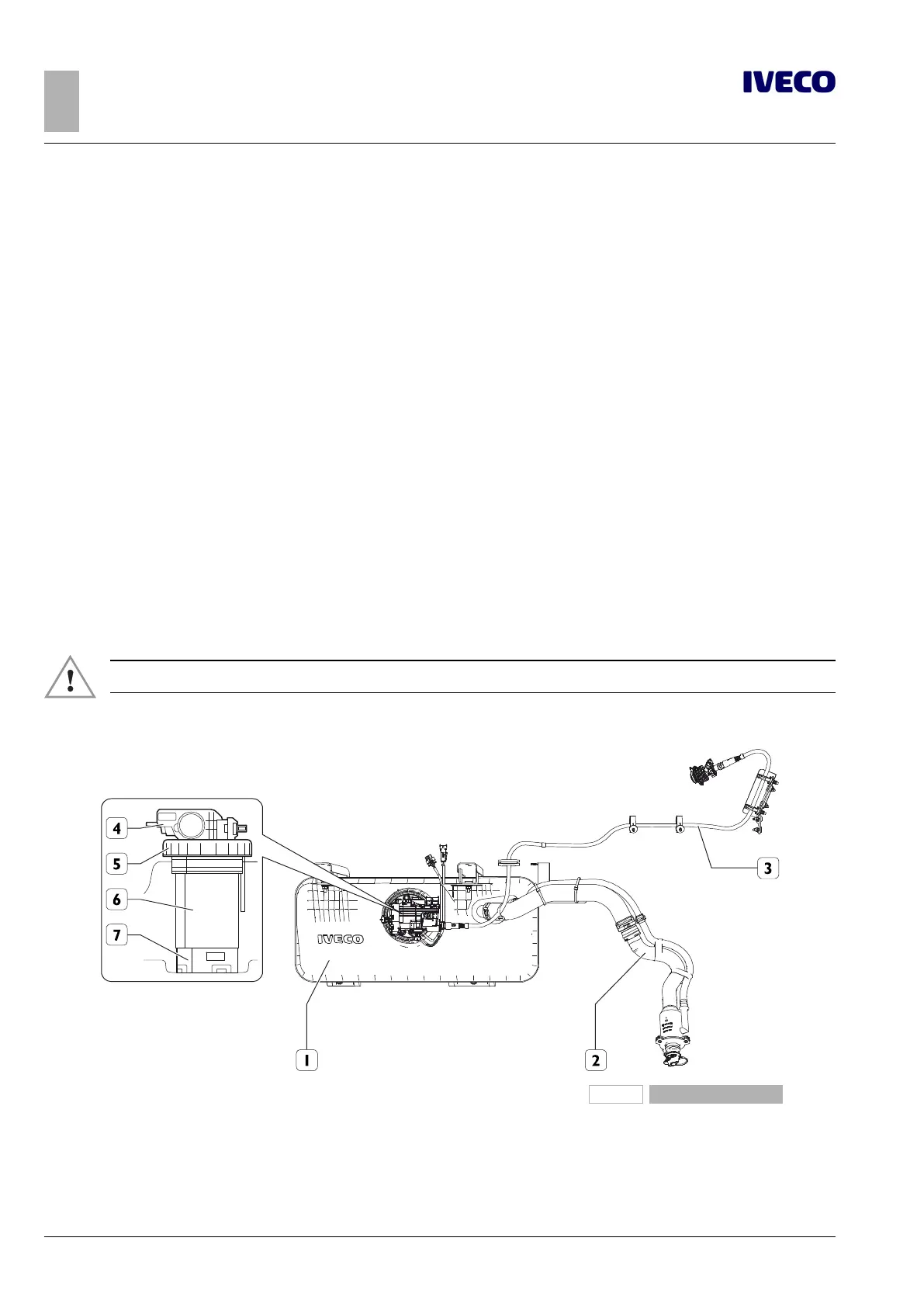

AdBlue tank

▶ No modifications to the original tank are permitted.

208931

Figure 2

1. AdBlue tank

2. AdBlue refuelling filler

3. Heated pipe for AdBlue delivery to dosing module DM

4. SM Pumping module

5. Fastening ring nut

6. Heating pot

7. Locking ring welded to tank housing

Loading...

Loading...