8

DAILY MCA2014 4x4 ‒ BODYBUILDER INSTRUCTIONS

CHASSIS INTERVENTIONS

2.2 DRILLS ON THE CHASSIS

– Printed 603.95.994 – 1 Ed. - Base 05/2015

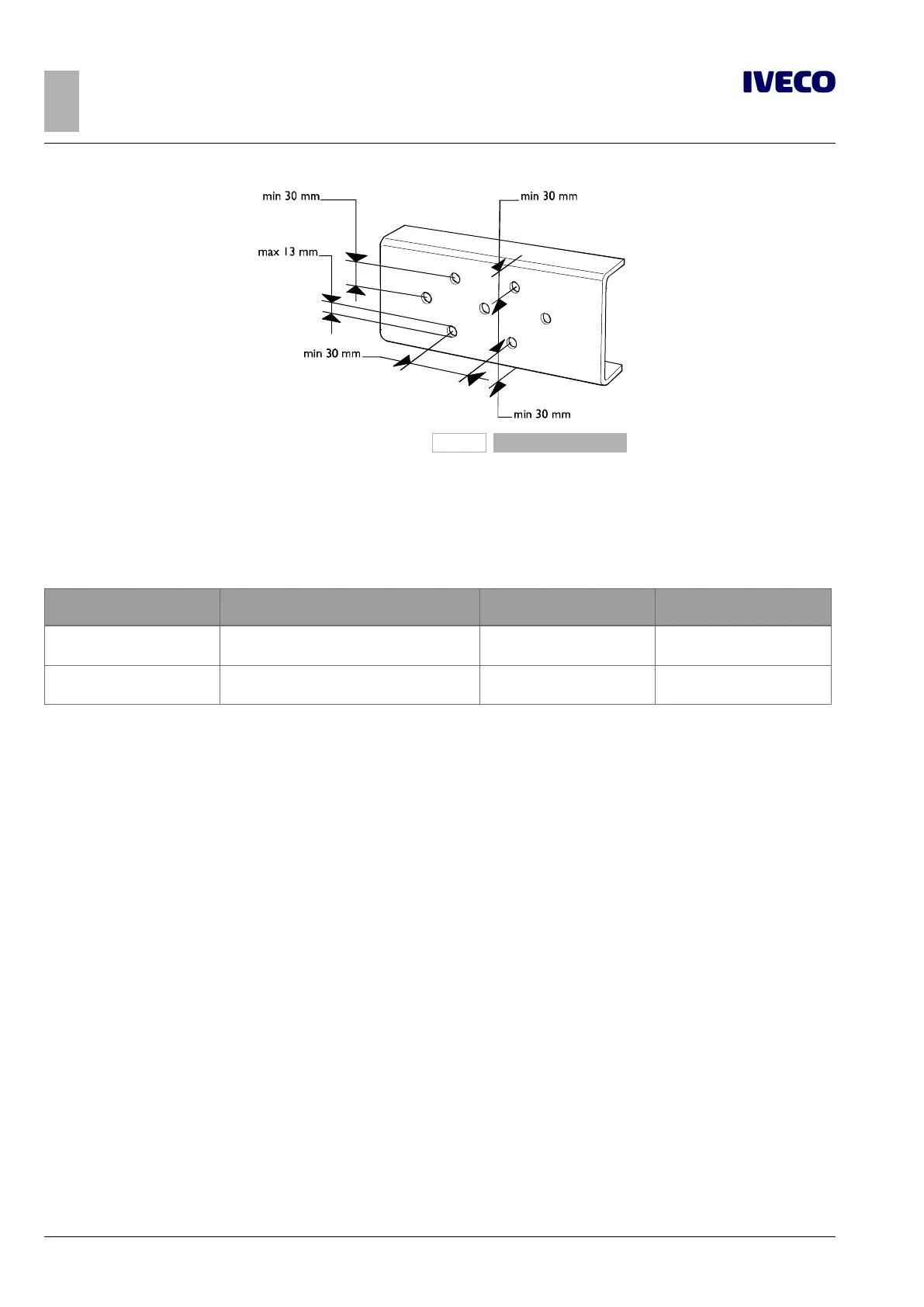

102420

Figure 2

Screws and nuts

We generally recommend the use of the same type and class of screws and nuts as those employed for similar anchorages on the

original vehicle (see Table 2.3).

Table 2.3 - Screws resistance classes

Resistance class Use

Breaking strength

[N/mm

2

]

Yield stress

[N/mm

2

]

8.8

Intermediate resistance screws (crossbars, shear

resistant plates, brackets)

800 640

10.9

High resistance screws (springs supports, stabiliser

bars and shock absorbers)

1000 900

Screws classed 8.8 and 10.9 must be well cleaned and, for applications using a screw with a diameter of ≤ 6 mm; we recommend

protection FeZnNi 7 IV.

Screw treatment allowed is Geomet or zinc coating. Geomet treated screws are discouraged when using them in welding opera-

tions.

Use flange headed screws and nuts if there is sufficient space.

Use nuts with an anti-unscrewing system and keep in mind that the tightening torque must be applied to the nut.

Sealing holes by welding

If new holes are located near old holes (see Figure 2), these last can be welded shut.

Good results are obtained by:

● chamfering the outer edge of the hole;

● applying a copper plate on the inner edge of the side member to hold the welding material;

● welding the side member on both sides with elimination of all residual material.

Holes of 20 mm diameter can be sealed off by using chamfered washers welded on both sides.

Loading...

Loading...