DAILY MCA2014 4x4 ‒ BODYBUILDER INSTRUCTIONS

APPLICATIONS OF SUPERSTRUCTURES

3.3 CONNECTION BETWEEN CHASSIS AND COUNTER CHASSIS

13

– Printed 603.95.994 – 1 Ed. - Base 05/2015

Connections with greater elasticity

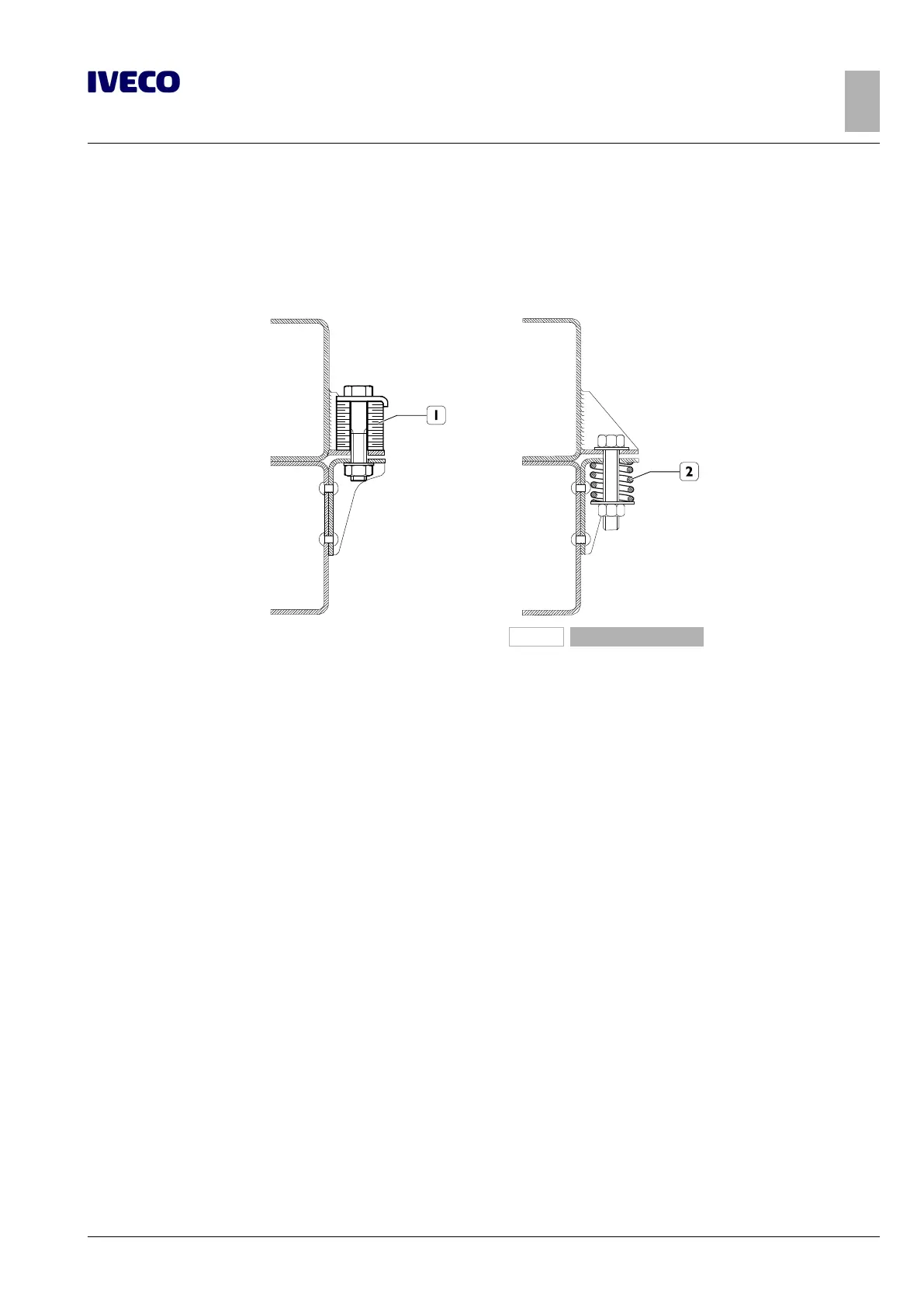

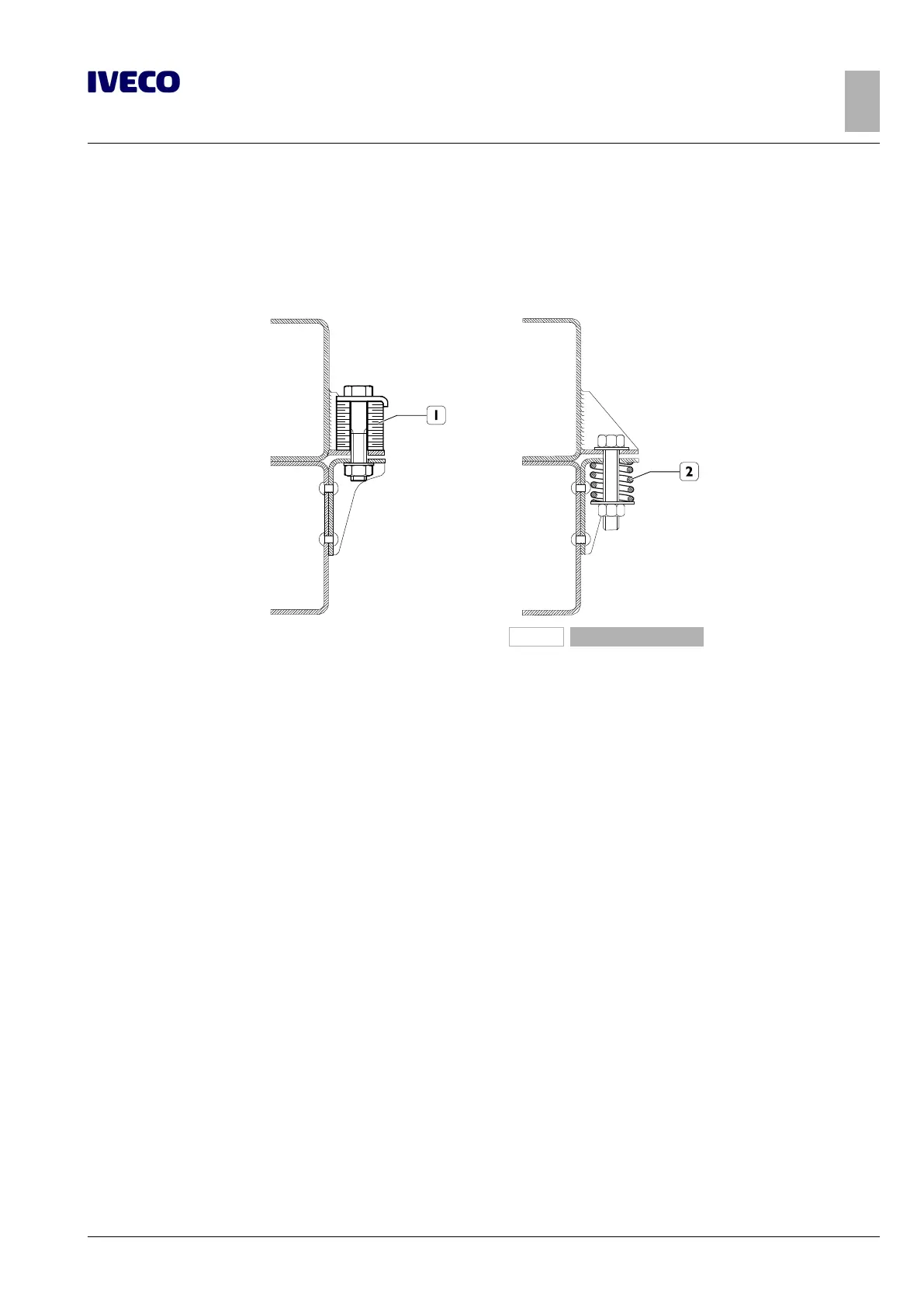

When the connection needs greater flexibility (e.g. vehicles with high stiffness of the superstructure such as vans, tanks, etc., used

on winding roads or in poor conditions, vehicles for special use, etc.), hardware similar to the type indicated in Figure 9 should be

adopted in the area behind the driver's cab.Brackets accompanied by rubber plugs (1) or coil springs (2) should be used.

193872a

Figure 9

1. Rubber block 2. Coil spring

Bear closely in mind that:

● the elastic element characteristics should be suited to the stiffness of the superstructure, the wheelbase and the type vehicle

use (irregular road conditions);

● stiffness must progressively increase for fixing points closer to the rear part of the chassis;

● the overall connection capacity must also include fixing points resistant to shear stress to be positioned near the rear suspen-

sion.

Consequently, the first fixing behind the cab must be made using one of the solutions shown in Figure 9; especially when the vehicle

has a long wheelbase, this solution must also be replicated for the next fixing, modifying only the stiffness.

For example, in the case of brackets with rubber pads, elements must be used having the same hardness (sh = 83), assembled in

dual pairs for the first bracket and single pairs for the next bracket, with M10 screws and tightening torques of di 15-18 Nm.

Also bear in mind that:

● for rubber plugs, use materials that ensure good elasticity over time.

● every solution requires the preparation of appropriate instructions for interval controls and possible resetting of the tightening

torques of parts.

● In versions where the vehicle is lifted by hydraulic stabilisers (e.g. cranes, aerial work platforms), limit the collapse of the elastic

element to ensure sufficient cooperation of the counter chassis and avoid excessive bending moments on the original chassis.

Also bear in mind that:

1. in the case of superstructures that generate high bending and twisting moments (e.g. a crane behind the cab), the counter

chassis must be properly sized to support them;

Loading...

Loading...