DAILY MCA2014 4x4 ‒ BODYBUILDER INSTRUCTIONS

APPLICATIONS OF SUPERSTRUCTURES

3.3 CONNECTION BETWEEN CHASSIS AND COUNTER CHASSIS

11

– Printed 603.95.994 – 1 Ed. - Base 05/2015

166685

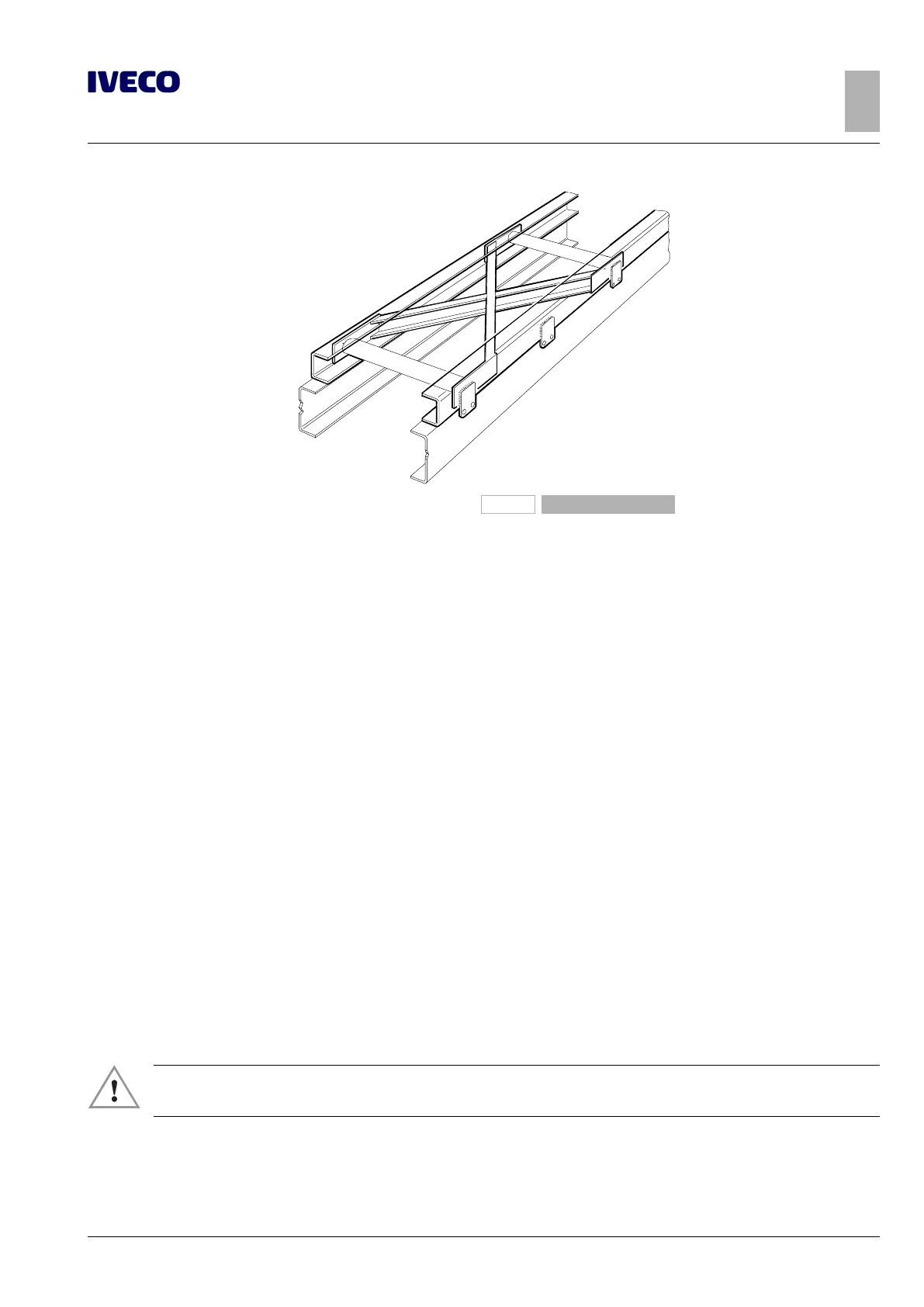

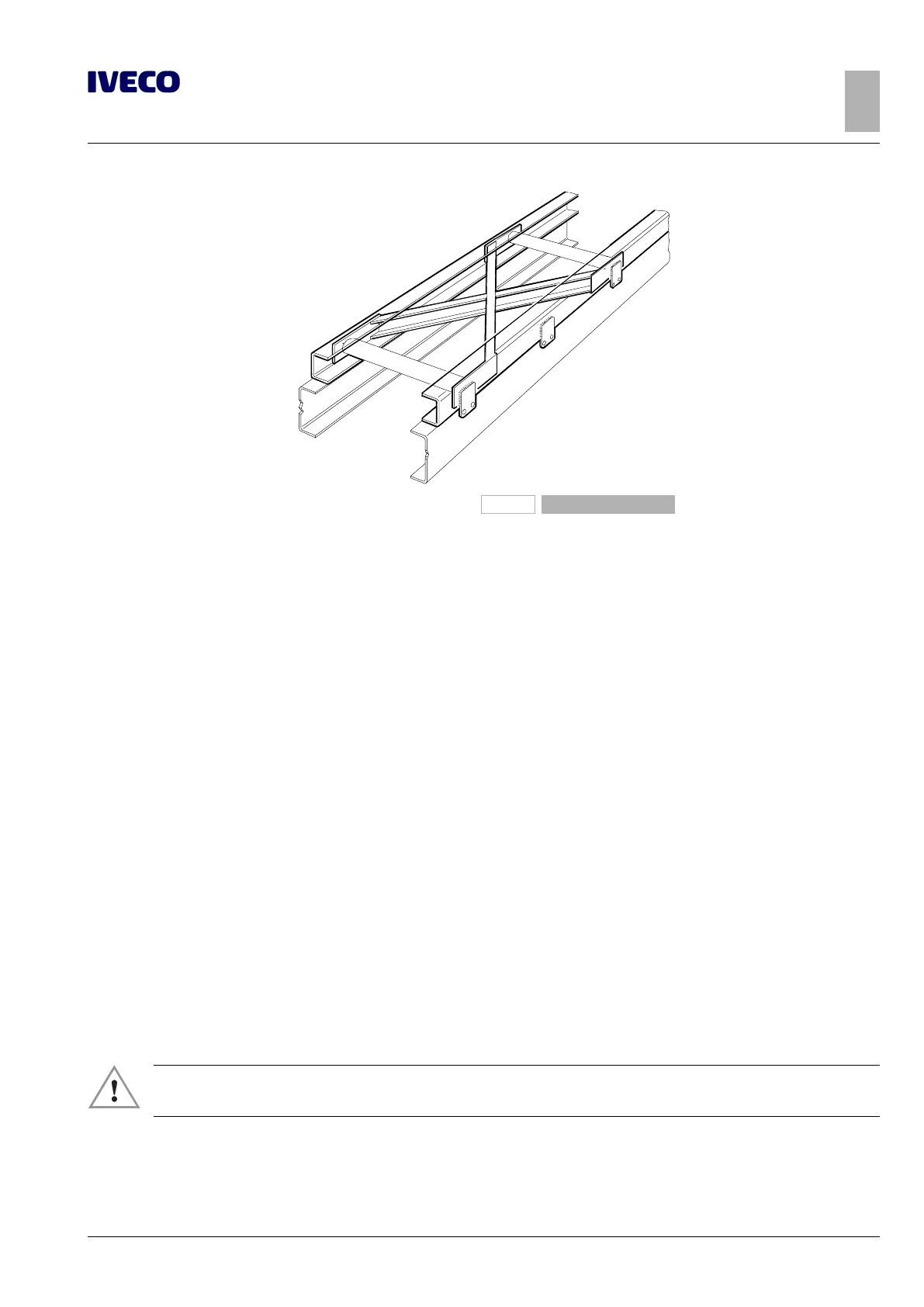

Figure 7

Self-supporting superstructures with counter chassis functions

The interposition of a counter chassis (longitudinal and transverse) can be omitted in the case of installation of self-supporting su-

perstructures (e.g. vans, tanks), or when the underlying structure of the equipment to be installed already has the counter chassis

conformation.

3.3 CONNECTION BETWEEN CHASSIS AND COUNTER CHASSIS

Choosing the type of connection

The choice of the type of connection to be used, if not provided by IVECO originally, is very important for the purposes of contri-

bution of the counter chassis in terms of strength and stiffness.

It can be elastic (brackets or clamps) or rigid, resistant to shear stress (plates sealed longitudinally and transversally); the choice must

be made according to the type of superstructure to be applied (see Chapters 3.4 to 3.14), evaluating the stresses that the added

equipment transmits to the chassis, both in static and dynamic conditions. Number, size and construction of the anchors, reasonably

allocated in the length of the counter chassis, must be such as to ensure a good connection between the chassis and the counter

chassis.

The screws and the clamps must have material strength class of not less than 8.8, and the nuts must be fitted with systems that

prevent unscrewing. The first anchor should be positioned, if possible, at a distance of about 250÷350 mm from the front end of

the counter chassis.

The elements for the original connection already existing on the vehicle chassis must be preferred.

The respect of the distance indicated above for the first anchoring must be ensured especially in the presence of superstructures

with concentrated loads behind the cab (e.g. crane, front body tilting cylinder, etc..), in order to improve the magnitude of the

chassis stresses and contribute more to the stability. Provide additional connections if necessary.

If you have to install a superstructure with features different from those for which the chassis was designed (e.g. a tipping body on a

chassis built for a fixed body) suitable connections must be provided (e.g. replacement of brackets with shear resistant plates in the

rear area of the chassis).

▶ In anchoring the structure to the chassis, welding must not be performed on the vehicle chassis,

nor may holes be drilled into its wings.

Loading...

Loading...