DAILY MCA2014 4x4 ‒ BODYBUILDER INSTRUCTIONS

APPLICATIONS OF SUPERSTRUCTURES

3.1 CONSTRUCTION OF THE COUNTER CHASSIS

7

– Printed 603.95.994 – 1 Ed. - Base 05/2015

204635

Figure 1

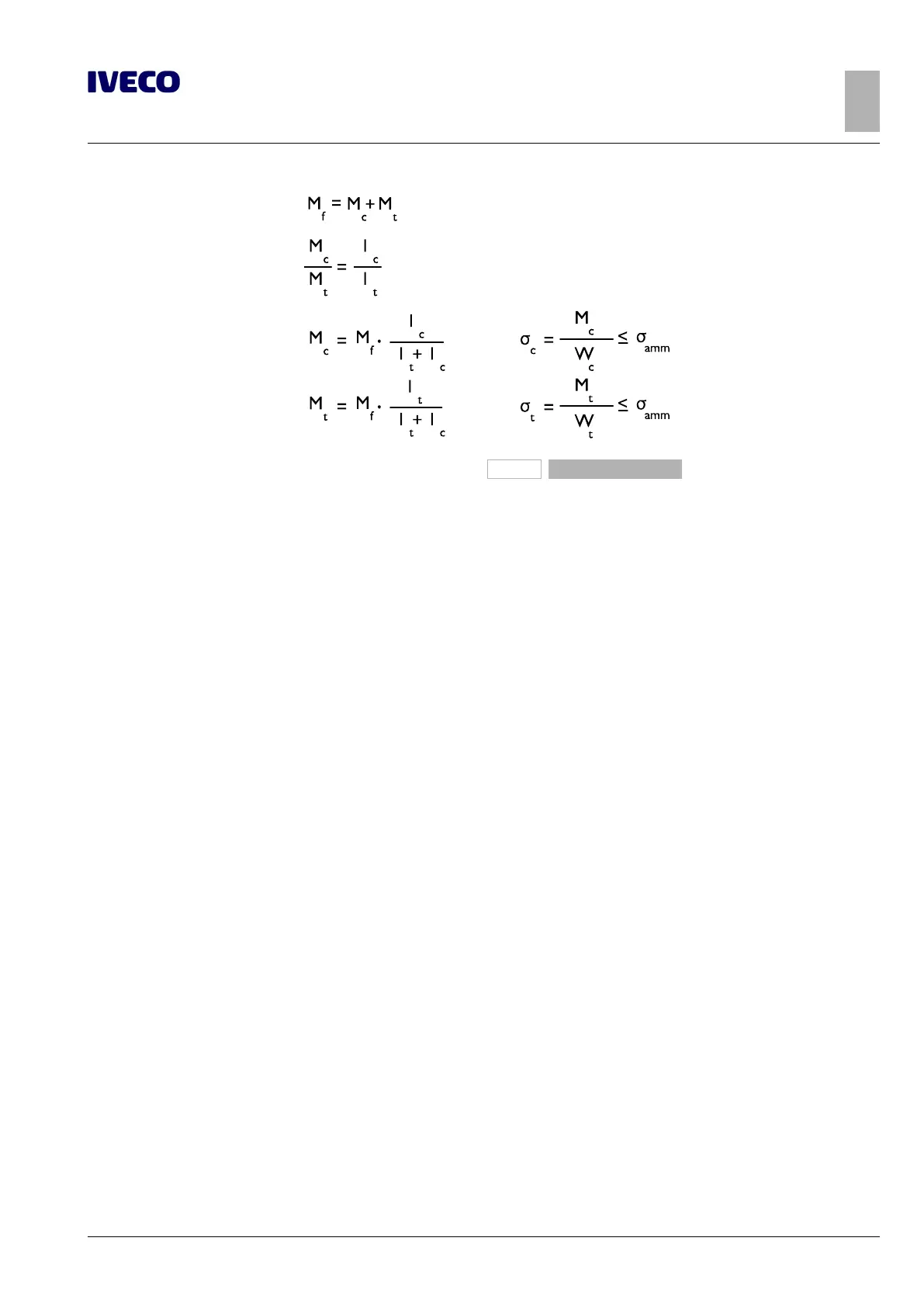

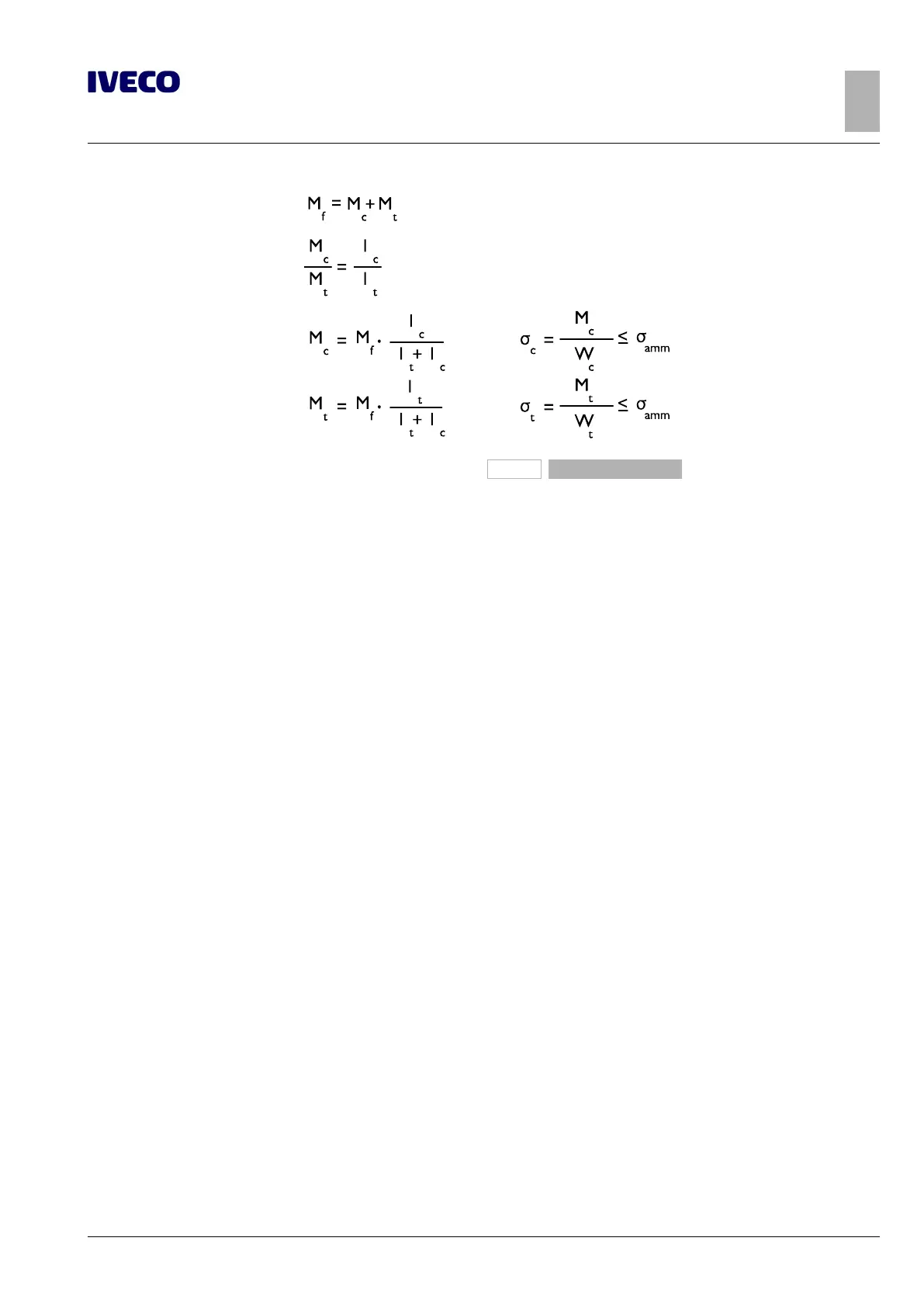

M

f

= static bending moment generated by the superstructure [Nmm]

M

c

= proportional share of the static bending moment M

f

applied to the counter-chassis [Nmm]

M

t

= proportional share of the static bending moment M

f

applied to the chassis [Nmm]

I

c

= moment of inertia of the section of the counter-chassis [mm

4

]

I

t

= moment of inertia of the section of the chassis [mm

4

]

σ

c

= maximum static stress applied to the counter-chassis [N/mm

2

]

σ

t

= maximum static stress applied to the chassis [N/mm

2

]

W

c

= resistance module of the section of the counter-chassis [mm

3

]

W

t

= resistance module of the section of the chassis [mm

3

]

σ

amm

= maximum static stress allowed on chassis [N/mm

2

] see chapter 2.1, Paragraph "Stresses on the chassis" ( ➠ Page 7)

Aluminium counter chassis

When using materials with different characteristics from those of steel (e.g. aluminium), the size and structure of the counter

chassis must be appropriately adjusted.

1. When the contribution of the counter chassis is mainly that of providing a uniform distribution of load and the chassis has

the fundamental task of resistance, aluminium longitudinal profiles having dimensions similar to those indicated for the steel

can be used. Typical examples are fixed bodies, vans and tanks, provided that the supports are continuous and close-up or

in the immediate vicinity of the suspension mounts. An exception is made in cases where high stresses on the chassis require

relatively large sections of the steel reinforcement, cut-resistant links.

2. When the counter chassis is prompted to make a contribution in terms of strength and hardness (e.g. superstructures with

high concentrated loads, tipping bodies, cranes, centre axle trailers, etc..), the use of aluminium is generally not recommended

and should be authorised from time to time by IVECO.

Please note that in defining the minimum size of the reinforcement profiles in addition to the limit of the allowable stress for

aluminium, reference must be made to the different Elastic Modulus with respect to steel (approx. 7,000 kg/mm

2

against 21,000

kg/mm

2

for steel) which involves greater dimensioning of the profiles.

Similarly, when the connection between the chassis and counter chassis is such as to ensure the transmission of the shear stresses

(connection with plates), in checking the stresses at the two ends of the individual section, it is necessary to define the new neutral

axis for this, on the basis of the different elastic modulus of two materials.

The collaboration requirement for aluminium means, in short, large and not very convenient dimensions.

Loading...

Loading...