DAILY MCA2014 4x4 ‒ BODYBUILDER INSTRUCTIONS

APPLICATIONS OF SUPERSTRUCTURES

3.3 CONNECTION BETWEEN CHASSIS AND COUNTER CHASSIS

15

– Printed 603.95.994 – 1 Ed. - Base 05/2015

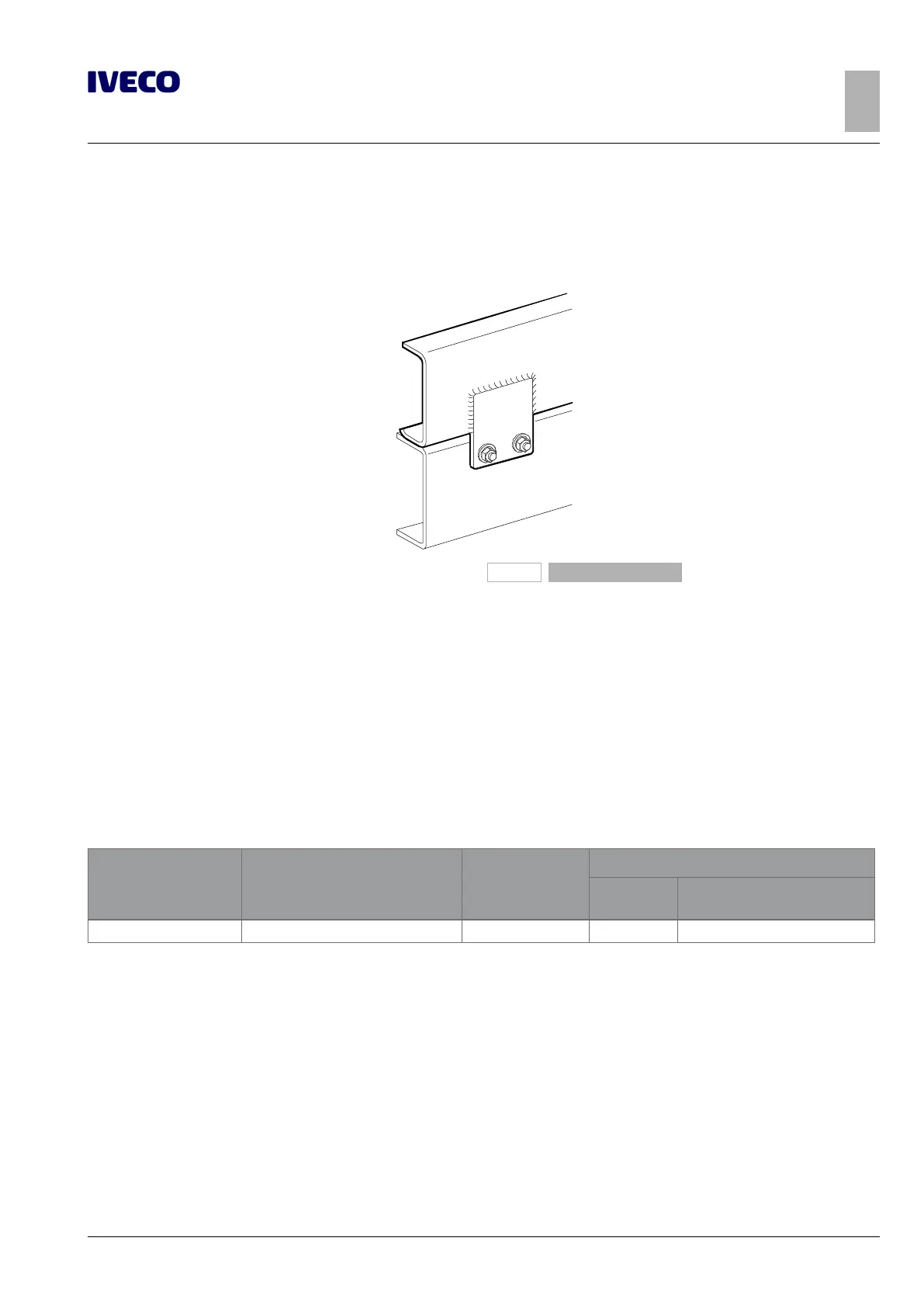

Connection with longitudinal and transverse sealing plates (rigid junction)

The type of mounting shown in Figure 11, made with plates that are welded or bolted to the counter chassis and fixed with nails or

screws to the vehicle chassis, ensures a good capacity for reacting to longitudinal and transverse thrusts and the greatest contribu-

tion to the stiffness of the assembly.

102462

Figure 11

For the correct use of these plates, please keep in mind that:

● the vertical rib of the chassis should be fastened only after making sure that the counter chassis is snug against the chassis itself;

● the distribution must be limited to the central and rear area of the chassis;

● the number and the thickness of the plates and the number of fixing screws must be adequate to withstand the bending mo-

ments and cutting of the section.

In cases where the superstructure generates high bending and twisting moments on the chassis and its resistant capacity should be

increased by adopting a cut-resistant connection between the chassis and the counter chassis, or if you want to contain the height

of the counter chassis as much as possible (e.g. centre axle trailers, crane on rear overhang, tail lifts, etc.), use the information sup-

plied in the table below (valid for all models):

Table 3.3

Ratio

height/section

chassis and counter

chassis

Max. distance between the centre

lines

of the cut-resistant plates

[mm]

(1)

Models

Minimum characteristics of the plates

Thickness

[mm]

Dimensions of the screws

(2)

(min. 3 screws per plate)

≤ 1.0 500 35S15/17, 55S15/17 5 M 12 (2 screws per plate)

(1)

The increase in the number of screws for each plate makes it possible to proportionally increase the distance between the plates (a

double number of screws may allow a greater distance between the plates). In high stress areas (e.g. the rear spring supports, the tandem

axle springs and the air springs), it is necessary to provide a distance between the plates, reduced as much as possible.

(2)

In the presence of contained thicknesses of the plates of the chassis and the counter chassis, it is advisable to connect by adopting spacer

bushes, in order to use longer screws.

Loading...

Loading...