DAILY MCA2014 4x4 ‒ BODYBUILDER INSTRUCTIONS

APPLICATIONS OF SUPERSTRUCTURES

3.2 ELEMENTS MAKING UP THE COUNTER CHASSIS

9

– Printed 603.95.994 – 1 Ed. - Base 05/2015

193867

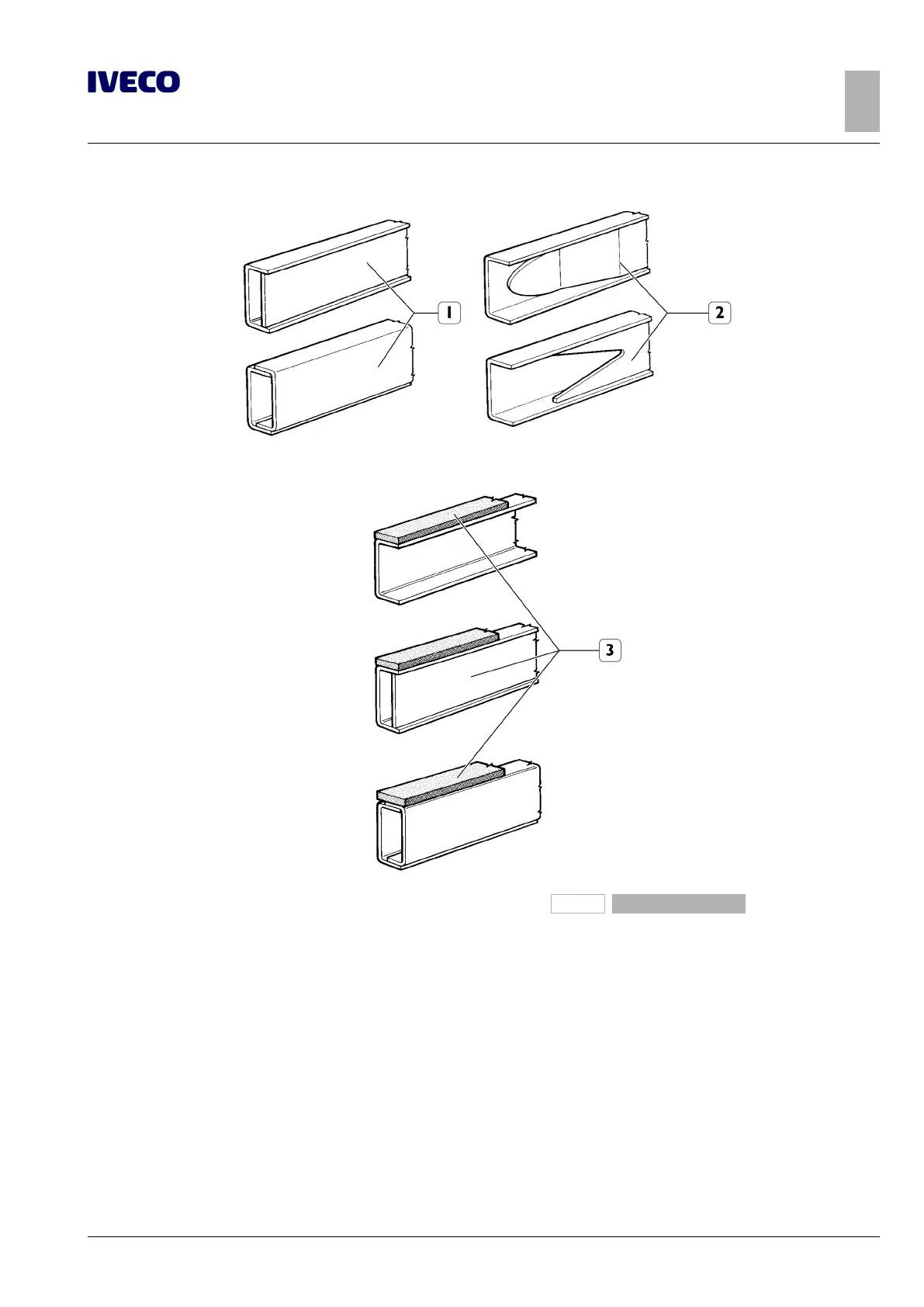

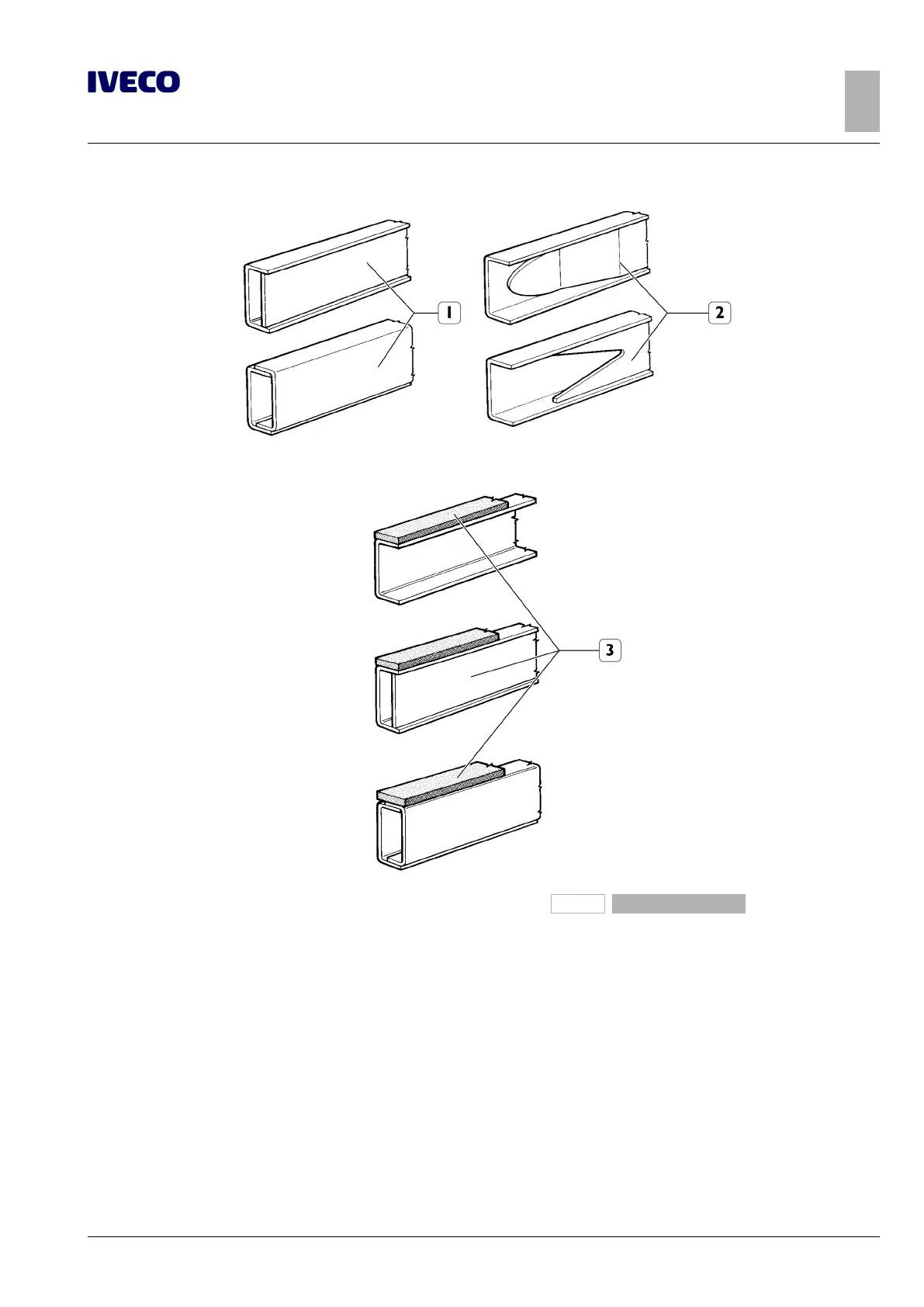

Figure 4

1. Normal boxed profiles

2. Gradual passage from the boxed section to the open

section

3. 15 mm lintel (width of the wing of the profile)

It is necessary to create continuity of support between the profiles of the counter chassis and those of the chassis; if this is not ob-

tained, the continuity can be restored by means of interposition of strips of sheet metal or light alloy.

If there is to be a rubber undercrawl element we recommend characteristics and thicknesses similar to those used for normal

production (hardness 80 Shore, max thickness 3 mm). Its use can prevent abrasive actions that can cause corrosion in the joining

between materials of different composition (e.g. aluminium and steel).

The dimensions prescribed for the side members of the various types of superstructures are the recommended minimum values

and, as a rule, are valid for vehicles with wheelbases and rear overhangs provided as standard (see Tables from 3.4 to 3.8). In all

cases similar profiles can be used, but with moments of inertia and resistance that are not lower. These values can be obtained

from the technical documentation of the profile manufacturers.

Loading...

Loading...