– 26 –

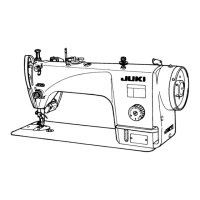

Tighten (turn clockwise) oil amount adjustment screw ❶ to increase the amount of oil in the hook, or loosen

(turn counterclockwise) to decrease it.

❷

❹

❸

❶

Decrease

Increase

"When using RP hook (hook for dry head) for DDL-9000C-FMS type"

1. Remove hook driving shaft oil wick setscrew ❷ and attach hook driving shaft stopper screw

❸ (part number : 11079506) and rubber ring ❹ (part number : RO036080200).

2. Loosen oil amount adjustment screw ❶ up to the minimum so as to reduce the oil amount in

the hook. However, do not completely stop the oil and be careful not to allow oil adjustment

screw ❶ to come off.

3. Never drain the oil in the oil tank even when RP hook (hook for dry head) is used.

3-12-1. Adjusting the amount of oil in the hook

3-12. Adjusting the amount of oil (oil splashes) in the hook

WARNING :

Be extremely careful about the operation of the machine since the amount of oil has to be checked

by turning the hook at a high speed.

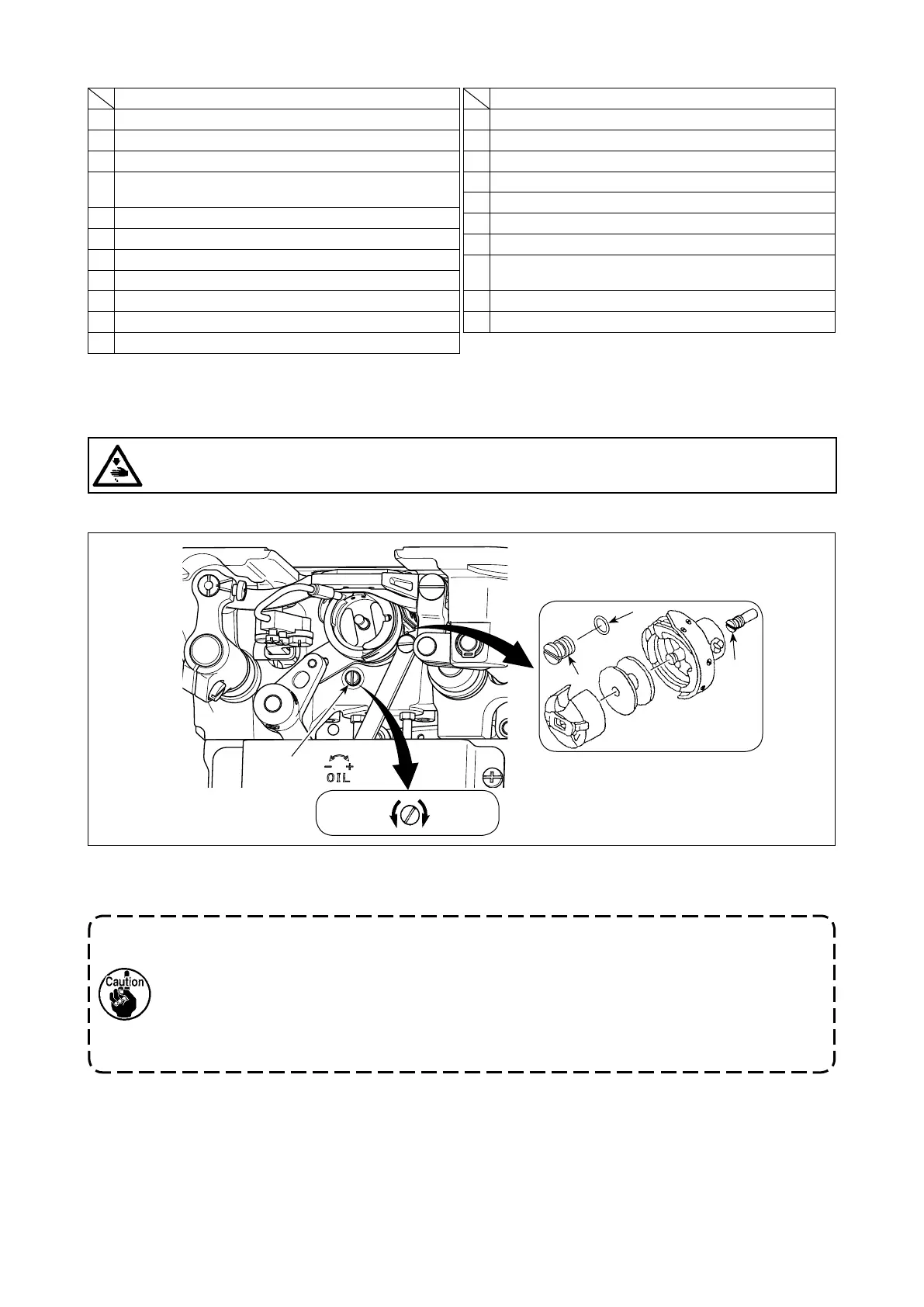

Function item

1 Optional input function is not provided

2 Needle up / down compensating stitching

3 Back compensating stitching

4 Function of canceling once reverse feed stitching at

the end of sewing

5 Thread trimming function

6 Presser foot lifting function

7 One stitch compensating stitching

8 Material edge sensor input

9 Function of prohibiting depressing front part of pedal

10 Function of prohibiting thread trimming output

11 Low speed command input

[Description of operations of the custom switch]

Function item

12 High speed command input

13 Needle lifting function

14 Reverse feed stitching switch input

15 Soft start switch input

16 One-shot speed command switch input

17 Backward one-shot speed command switch input

18 Safety switch input

19 Automatic reverse feed stitching cancellation/addition

switch

20 Sewing counter input

21 One-touch type changeover switch

Loading...

Loading...