Adjustment Procedure

Results of Improper Adjustment

1. Turn the ywheel until the needle bar ❷ comes to its lowest

position, and loosen the needle bar connecting setscrew ❶.

2. Determine the needle bar height.

Adjust the engraved marker line (marker line A for the DB

needle and marker line B for the DA needle) of the needle bar

❷ to the lower end of the needle bar lower metal ❸ and tighten

the needle bar connecting setscrew ❶. (Be careful not to tighten

the needle bar connecting setscrew ❶ too much.)

3. Determine the mounting position of the hook ❺.

Turn the three hook setscrews in the direction of ywheel

forward revolutions to raise the needle bar ❷. In this direc-

tion, adjust the engraved marker line (marker line C for the DB

needle and marker line D for the DA needle) to the lower end of

the needle bar lower metal ❸.

4. In this state, adjust the blade point ❺ of the inner hook to the

center of the needle ❹ so that a clearance of 0.04 to 0.1mm

(goal value) is secured between the needle ❹ and the hook ❺.

Since then, rmly tighten the three hook setscrews.

(Cautions) The needle bar ❸ of the DDL-9000C-FMS becomes

black because a special coating is applied to the

needle bar ❸. When it is difcult for you to check a

marker line, make the room brighter using a light and

check it.

<Information about the dry hook>

Use the following part number.

The hook part numbers come in two types according to the speci-

cations.

22890206 (without the needle guard)

22890404 (with the needle guard)

22890305 (22890206 with special surface treatment)

(Cautions) The dry hook (RP hook) tends to collect thread

chips and material dust. This can cause malfunction

or defective stitches. Periodic cleaning is required.

<Lubricated hook K: Available separately>

This is a hard blade point hook with a needle holder applicable

to needle size #9 (#65).

Where a thin needle has to be used for reasons of sewing pro-

cesses, this type of hook is applicable to the prevention of stitch

skipping and needle breakage.

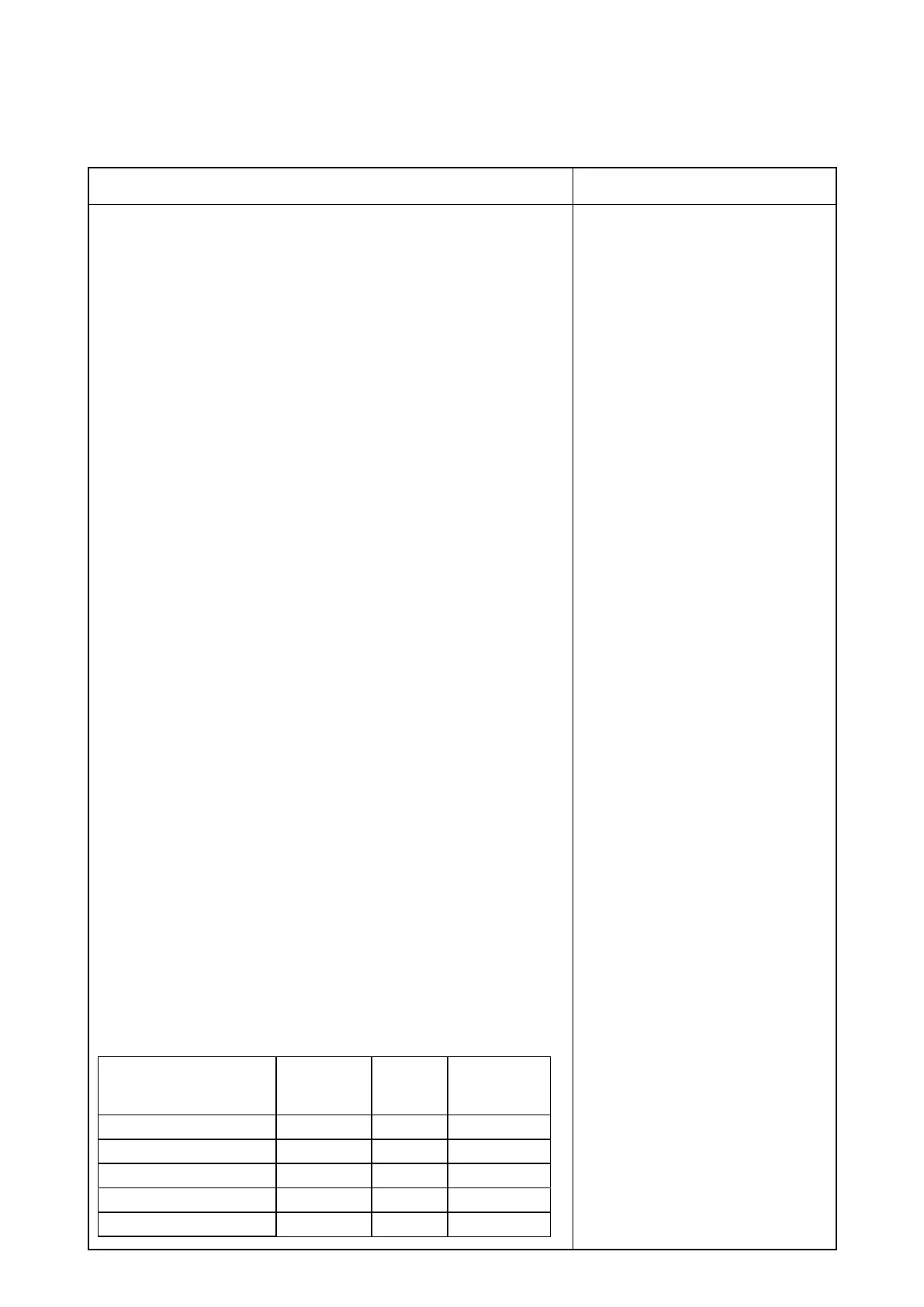

About the needle bar

Specications Part No.

Amount

of looper

return

Needle shank

DDL-9000C-SMS,FMS 22886904 1.8mm φ 1.64

DDL-9000C-SMS,FMS 22887004 1.8mm φ 2.02

DDL-9000C-SMS,FMS 40086602 1.8mm φ 1.64

DDL-9000C-SMS,FMS 40086604 1.8mm φ 2.02

DDL-9000C-SSH,FSH 40061767 2.3mm φ 2.04

◦ If this clearance is too small, the

blade point of the hook ❺ may be

damaged.

Too much clearance may give rise

to stitch skipping.

◦ When you use a dry hook, buy

and mount the parts that stop the

hook oil quantity.

Refer to "3.-(6)-5) Adjusting the

amount of oil in the hook".

– 7 –

Loading...

Loading...