77

Maintenance

Fault table

9.1 Fault Table

Only permit authorised personnel to rectify operational faults.

The table below shows possible faults and the action needed to

rectify them.

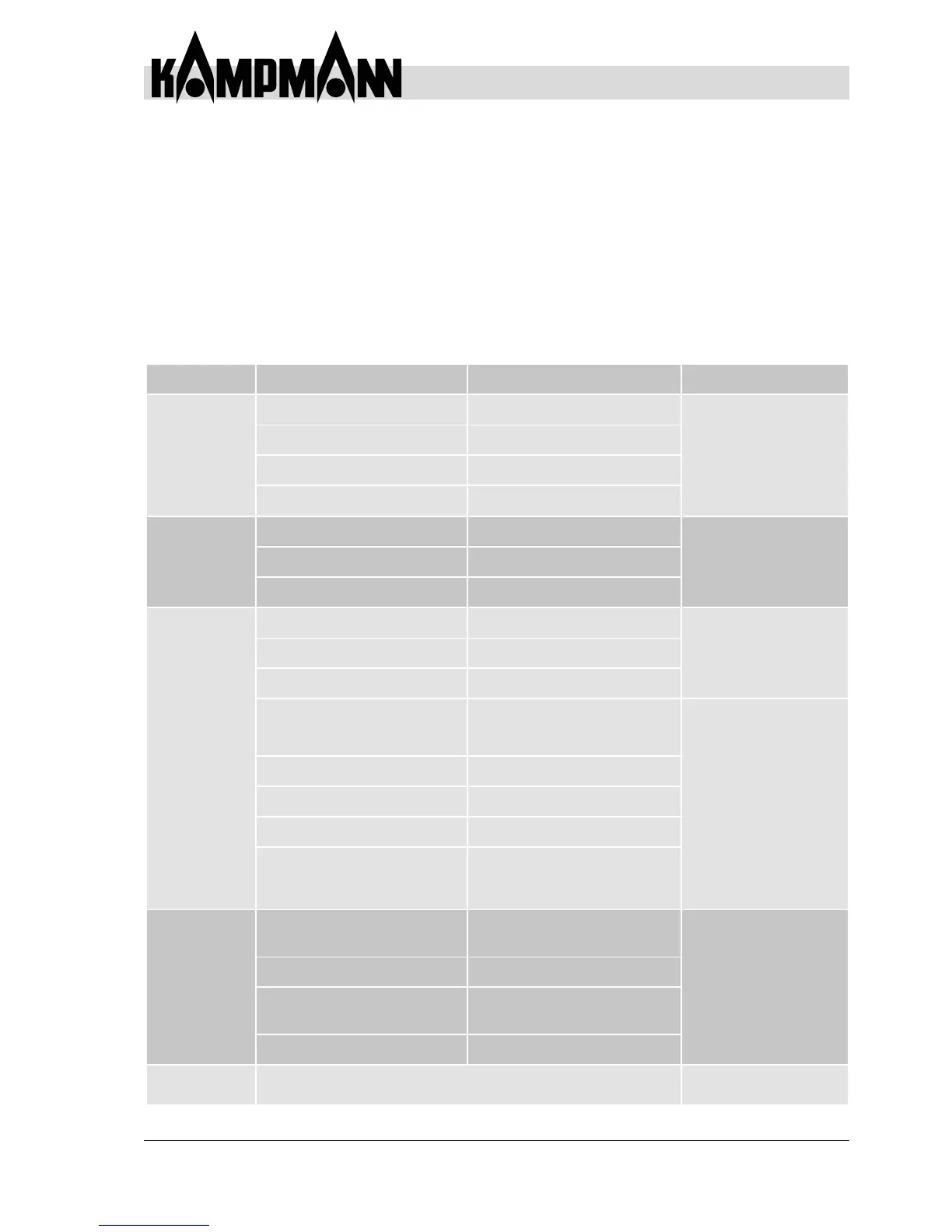

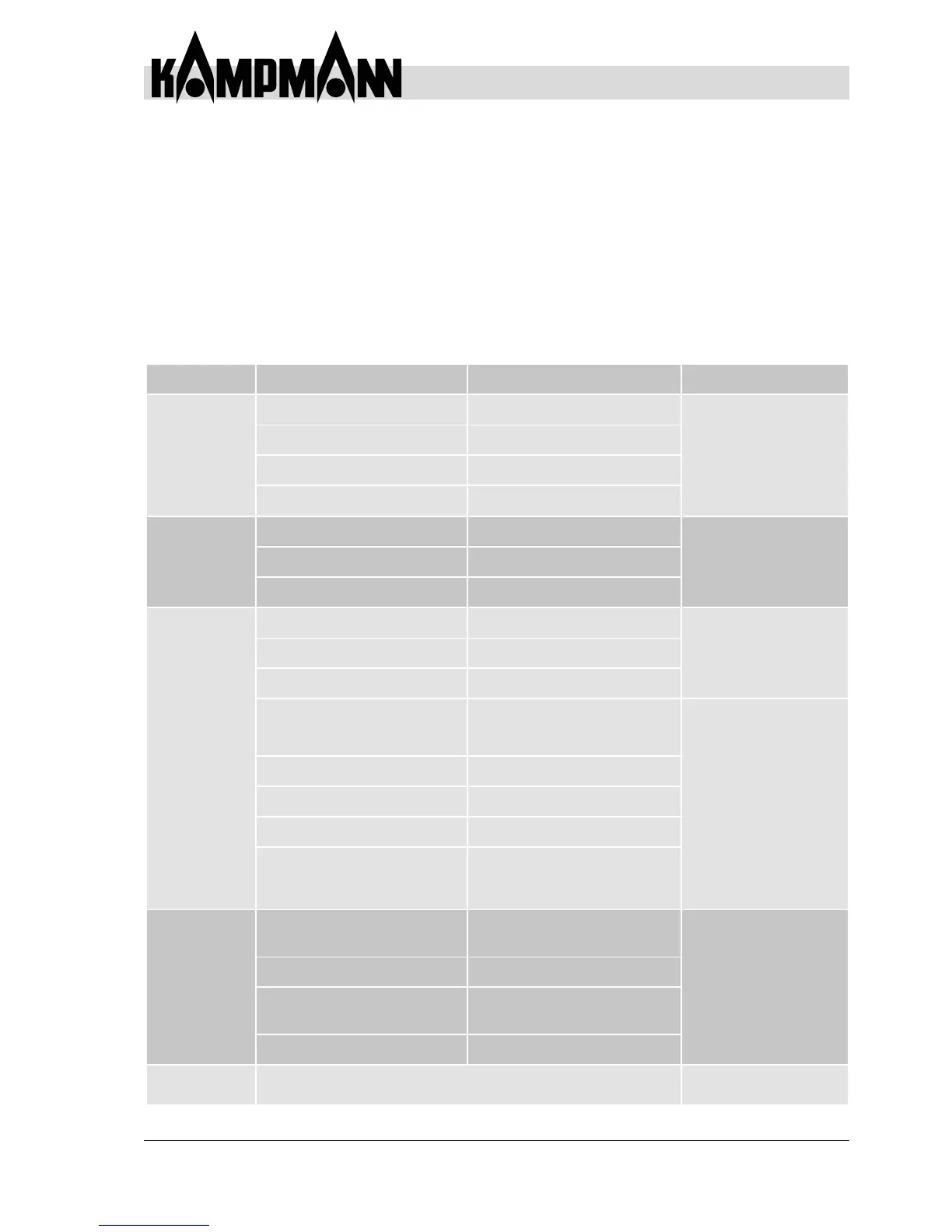

Fault Possible cause Actions

Personnel

Fan is not running

Unit switched off Switch on the unit by the control

Qualiedpersonnel

No power supply Check power supply and connect

Electrical cable not connected or

incorrectly connected

Check electrical wiring and correct if

necessary

No demand by controller, therefore

fans switch off

Change controller settings, if

required

Unit too loud

Speed too high Set lower fan speed

User/Caretaker

Air intake or air outlet openings

blocked

Free air intake and outlet grilles

Filter dirty Replacelter

Unit not heating

and cooling

sufciently

(LPHW/CHW)

Fan not switched on Switch on fan at controller

User/Caretaker

Air volume too low Set higher fan speed

Filter dirty Replacelter

No heating or cooling medium

Switch on heating and/or cooling

system, switch on circulation pump,

vent unit(s)/system

Qualiedpersonnel

Valves do not work Replace faulty valves

Water volume too low Check pump output, check hydraulics

Setpoint temperature on controller

set too low/high

Adjust temperature setting on

controller

Control unit with integrated sensor

and/or external sensor is exposed to

direct sunlight or positioned over a

heat source

Position control unit with integrated

sensor and/or external sensor in a

suitable location

Water escaping

from unit

Condensate drain not properly

installed

Check correct operation of

condensate pump, check and

cleancondensatedrain(iftted)

Qualiedpersonnel

Chilled water line incorrectly

insulated

Check insulation

Condensate drain outlets blocked

Clean condensate drains and check

for adequate gradient

Hydraulic connection not properly

done

Checkowandreturnandtighten,

if necessary

Condensate pump

is not running

properly

See separate instructions for the condensate pump

Qualiedpersonnel

Loading...

Loading...