50

50

Installation and Connection

Pipe connections

Theowandreturnconnectionsarelocatedasstandardontheleftsideof

the unit, seen from the front panel.

Route the pipes so that no mechanical stresses are transferred to the heat

exchanger and that the unit can be accessed with ease for maintenance

and repair work. Proceed as follows when hydraulically connecting up the

Venkonfancoil:

•

Shut off the heating/cooling medium and prevent it from being opened

accidentally before connecting to on-site pipework and making the

hydraulic connections on the basic unit, as there is a danger of scalding

from escaping heating medium!

•

With cooling units there is a danger to the user from the cold and a

danger to the environment from the use of glycol. Take appropriate

safety measures.

•

Removeprotectivecapsfromtheowandreturn.

•

With cooling mode, route pipes and valves directly over the side

condensate tray (accessory) to drain any condensate produced on the

pipes during cooling mode into the tray.

•

Seal and screw in connections, holding the nut to prevent it from shearing

off and twisting.

•

When connecting the unit to the on-site pipework, make sure that you

use a suitable tool to hold the unit‘s water connections in place!

•

Make sure that the pipes can be vented.

•

Use suitable insulating material (impermeable for cooling units)

•

Tighten all threadedconnectors once the pipes havebeen tted and

check that they are not under any tension.

We recommend the use of the valve kit when using

Kampmann casings. Consider the equipment under

the casing.

IMPORTANT NOTE!

Use a suitable tool to hold the union nut on the

heat exchanger in place during installation!

Ensure that the connections are not under any

mechanicaltensionwhentted!

IMPORTANT NOTE!

Ifthevalvekitispre-assembled,theowandreturn

can be swapped if space is tight.

See Chapter 6.10 page 51f Valve Kit Dimensions.

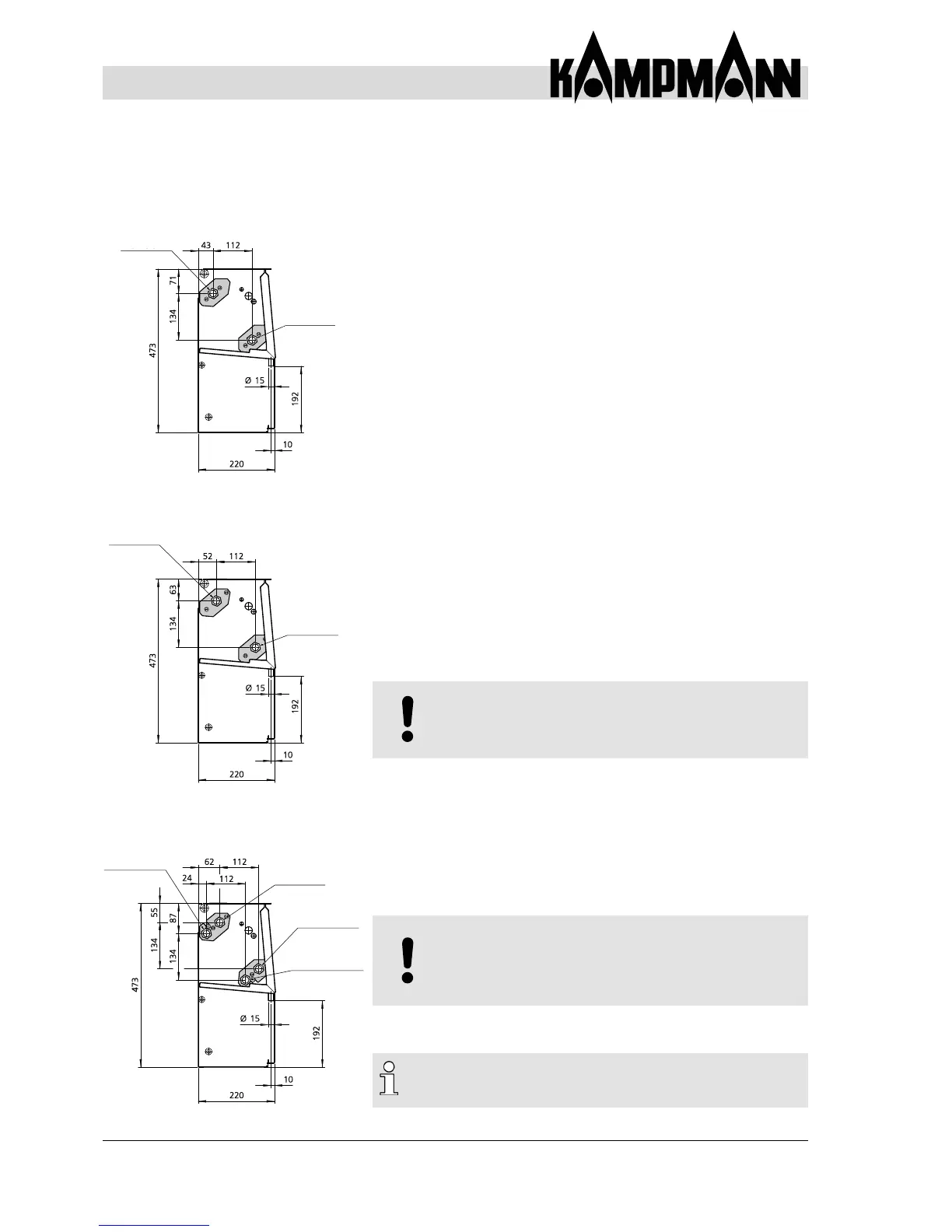

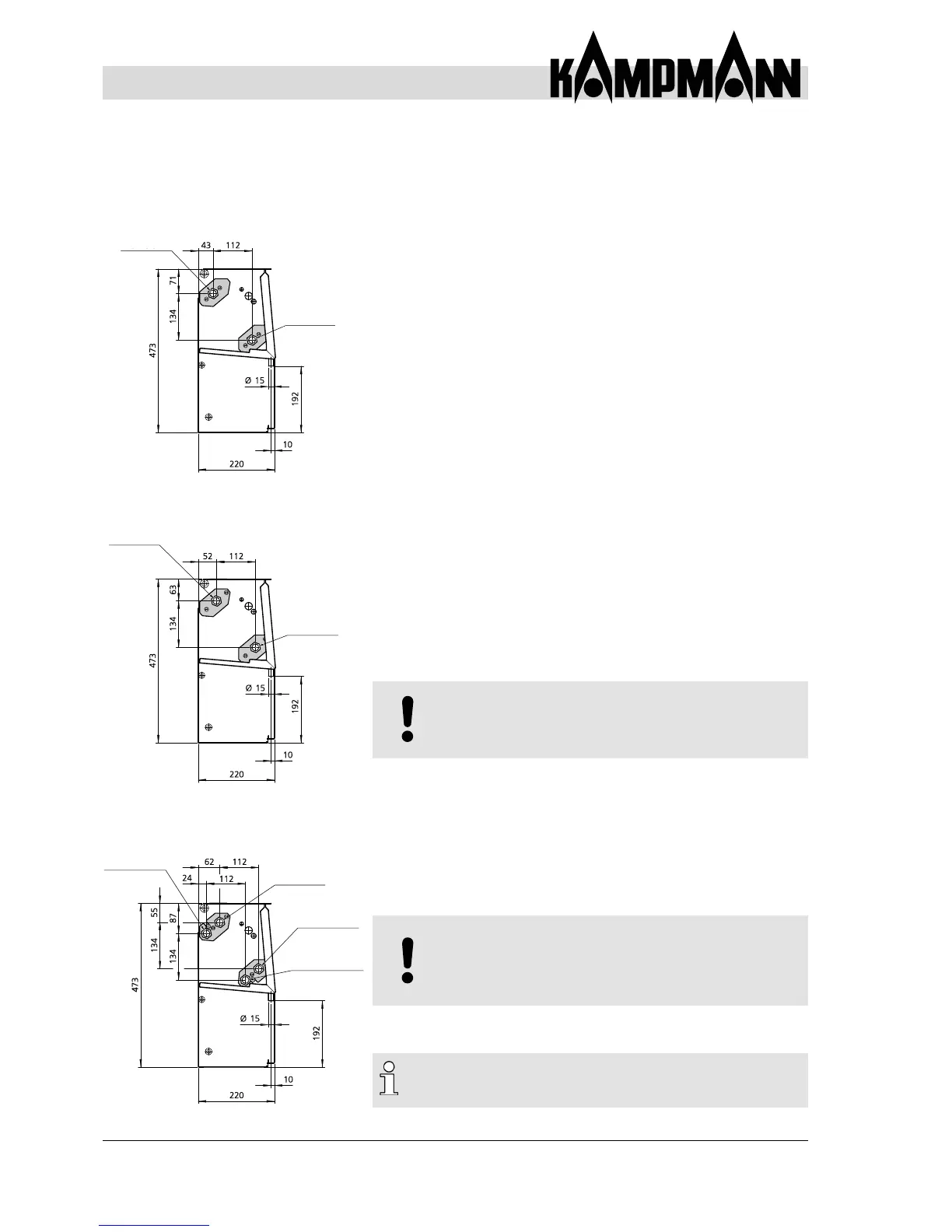

6.9 Connection to Pipework (for units with or without customer‘s valves)

Vorlauf 1/2“

Heizen

Rücklauf 1/2“

Heizen

Rücklauf *

Kühlen

Vorlauf *

Kühlen

Vorlauf *

Rücklauf *

Vorlauf *

Rücklauf *

Fig. 36: Dimensions of pipe

connections

2-pipe, 3-row

2-pipe, 4-row

4-pipe, 4-row

Flow

Flow

Flow 1/2“

Heating

Return

Return

Flow *

Cooling

Return *

Cooling

Return 1/2“

Heating

Loading...

Loading...