48

48

Installation and Connection

Hydraulic Connections

6.8 Hydraulic Connection

DesignfortheuseofunitsoperatedwithCHW:

-Thedimensionsofthesystemmayneedtobemodied.The

water volume is generally higher than with heating networks.

The normal temperature spread is around 6 K.

- Hydraulic shortcomings by the design, choice of distributor

system and poor hydraulic balancing are much more

noticeablethanwithhotwatersystemsandaredifcultto

detect and correct.

- The effective outputs have to be precisely tailored to actual

conditions of use. Take into consideration the possible rise

in temperature of the cooling medium, particularly along

longlengthsofpipework.(Forexample:Temperatureat

the generator 6/12 °C, temperature at the consumer 8/14 °C,

therefore loss of output)

- Check the suitability of all components (such as circulation

pumps etc.) for the use of CHW, noting the minimum

temperatures.

- The addition of anti-freeze has an adverse effect, for instance

it reduces cooling output at the generator and consumer

by impairing heat transfer / higher pressure losses in the

pipework by the lower viscosity of the cooling medium; the

consequenceishigherpumpcapacity:

Design: Notethefollowingpointsinthedesign:

- Fit end-to-end, vapour-impermeable insulation on all water-

carryingcomponents(pipes,valves,ttings)rightuptothe

unit (ensuring that the insulation goes as far as the disc under

the valves and ensuring that the insulation is adhered by the

condensate tray to the drip plate).

- Select suitable pipe brackets for cooling mode (chilled clamps)

- Install and check safety-related components (e.g. expansion

tanks,reliefandoverowvalves)

-Allowadequatespacefortheairow(airinletandoutlet)

-Positioncoolingunittotinwithttingsandinterior

architecture

- Make sure that any condensate produced can drain

away freely; check the free area of the condensate drain

connection/run condensate line along a gradient, without

bends or restrictions, to the on-site waste water line

- Size dimension of condensate line appropriately

-Protecttraps(iftted)inthecondensatelinefromdryingout

(possibly by the use of a ball trap)

- Use condensate pumps, noting the maximum delivery height,

if there is no natural gradient

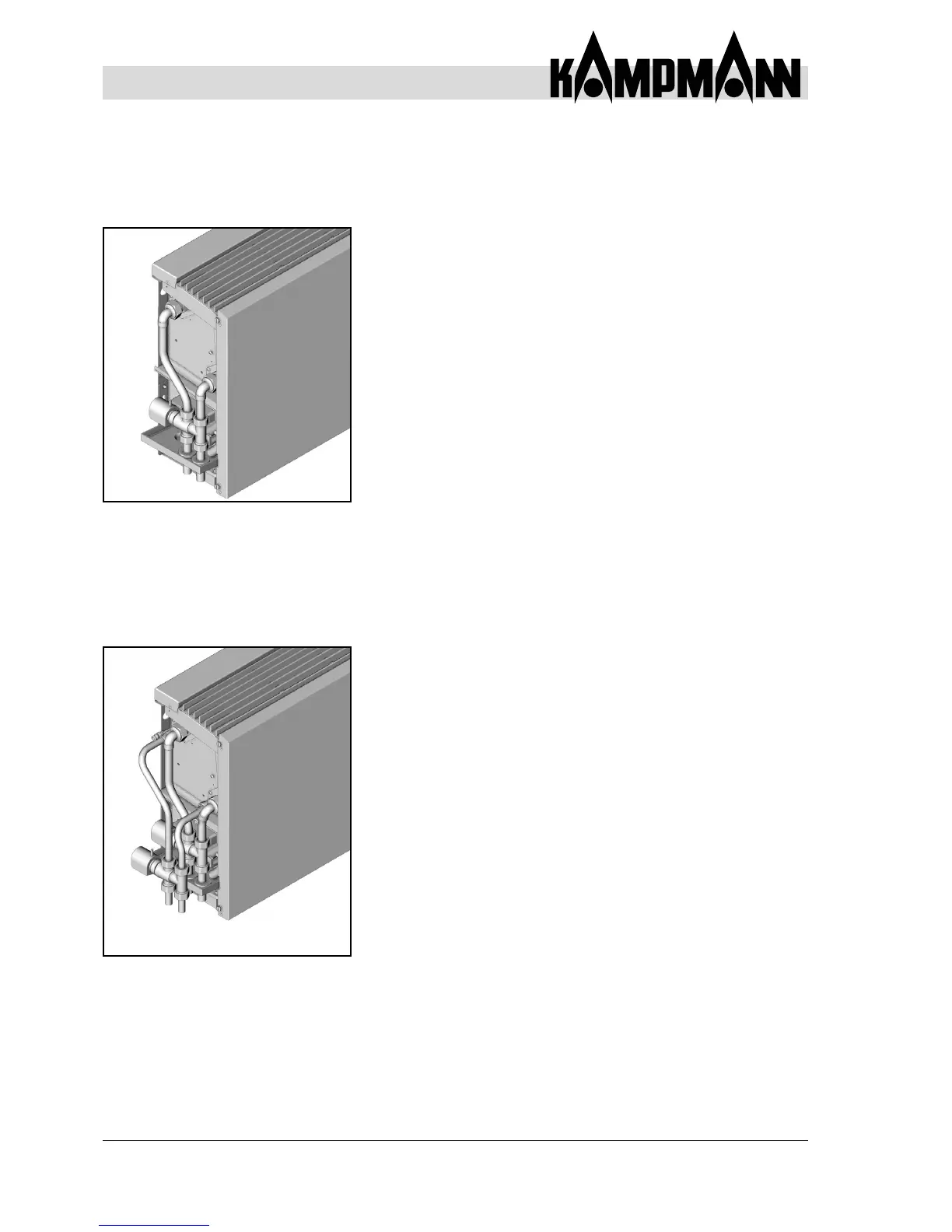

Fig. 32: 2-pipe system:

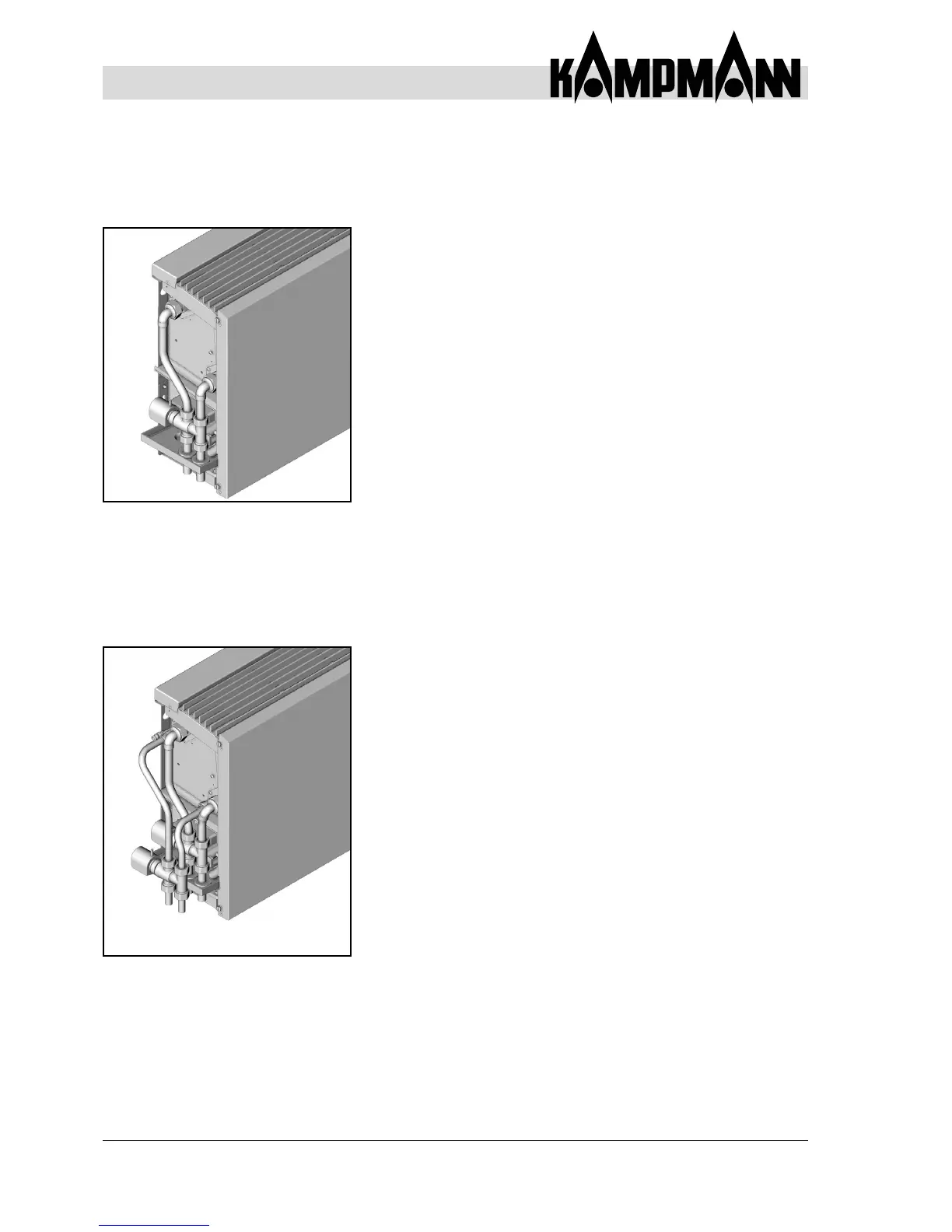

Fig. 33: 4-pipe system:

Loading...

Loading...