The machine is capable of receiving flat material up to a thickness of 75mm (3 inches). Operating

instructions identify full details of the dimensions of the materials that can be handled.

This Kern DHS model is designed for use indoors in a normal working environment. The intended

operating temperature range is 16 - 32 degrees Celsius and a relative humidity range from 50 -

75%.

Lighting

Ambient lighting must be sufficient for operators to view all parts inside of the machine. Ambient

lighting is sufficient if maintenance personnel can see all internal parts when fixed or hinged sheet

metal access panels have been removed and there is no need to provide additional internal lighting.

Internal lighting should achieve a light intensity of 100 to 200 Lux (Lumens/m

2

).

It is recommended that local ambient lighting should achieve a light intensity of 300 Lux

(Lumens/m

2

) around the HSE machine and in the immediate vicinity of those parts of the machine

where maintenance must be performed.

Uncrating

Carefully inspect the crate before it is unloaded from the delivery truck. Note any damage to the

crate with the shipping company driver and call Kern immediately.

Open the crate using a drill with a Phillips head bit. Once inside the crate inspect the laser system

and all boxes inside for any visible damage. All boxes may then be removed from the crate.

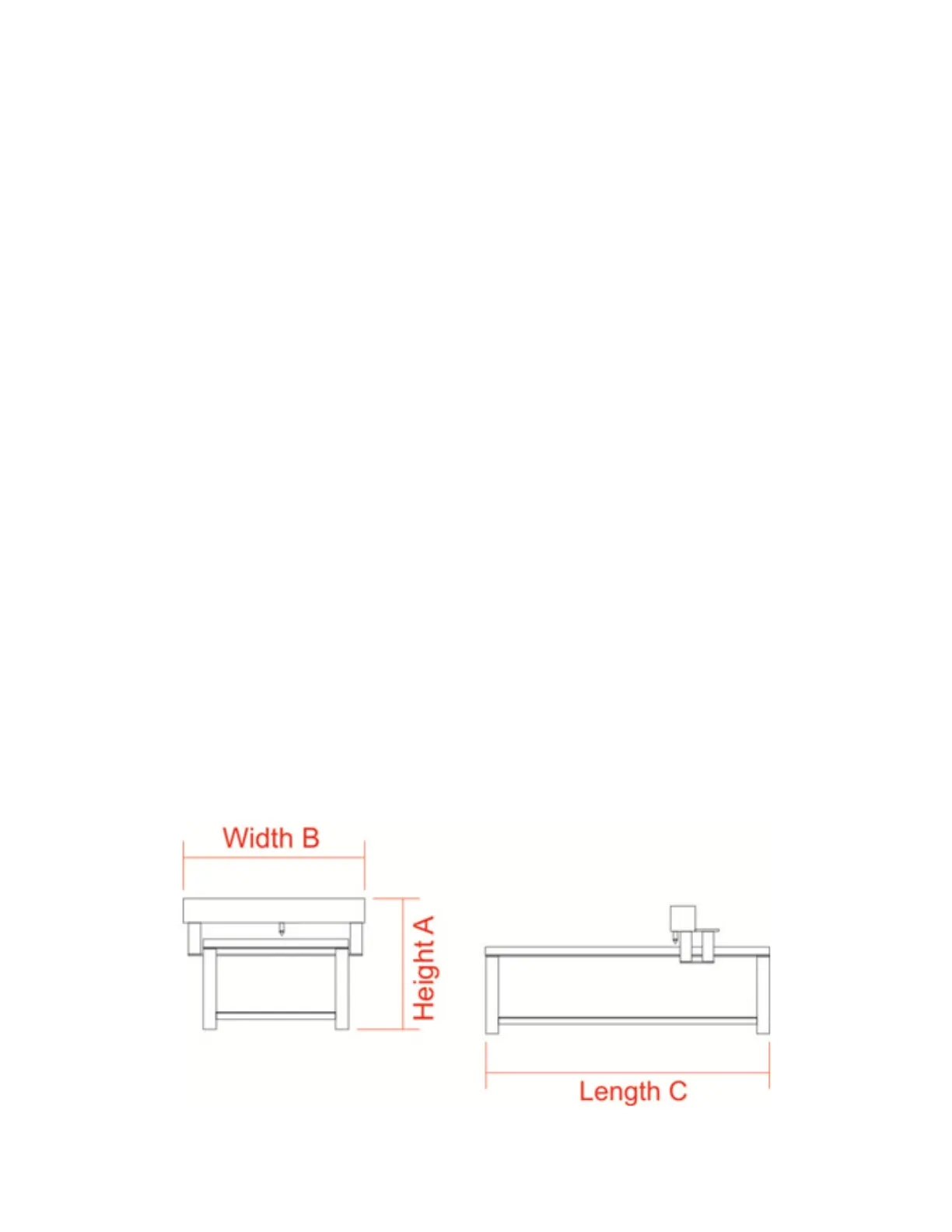

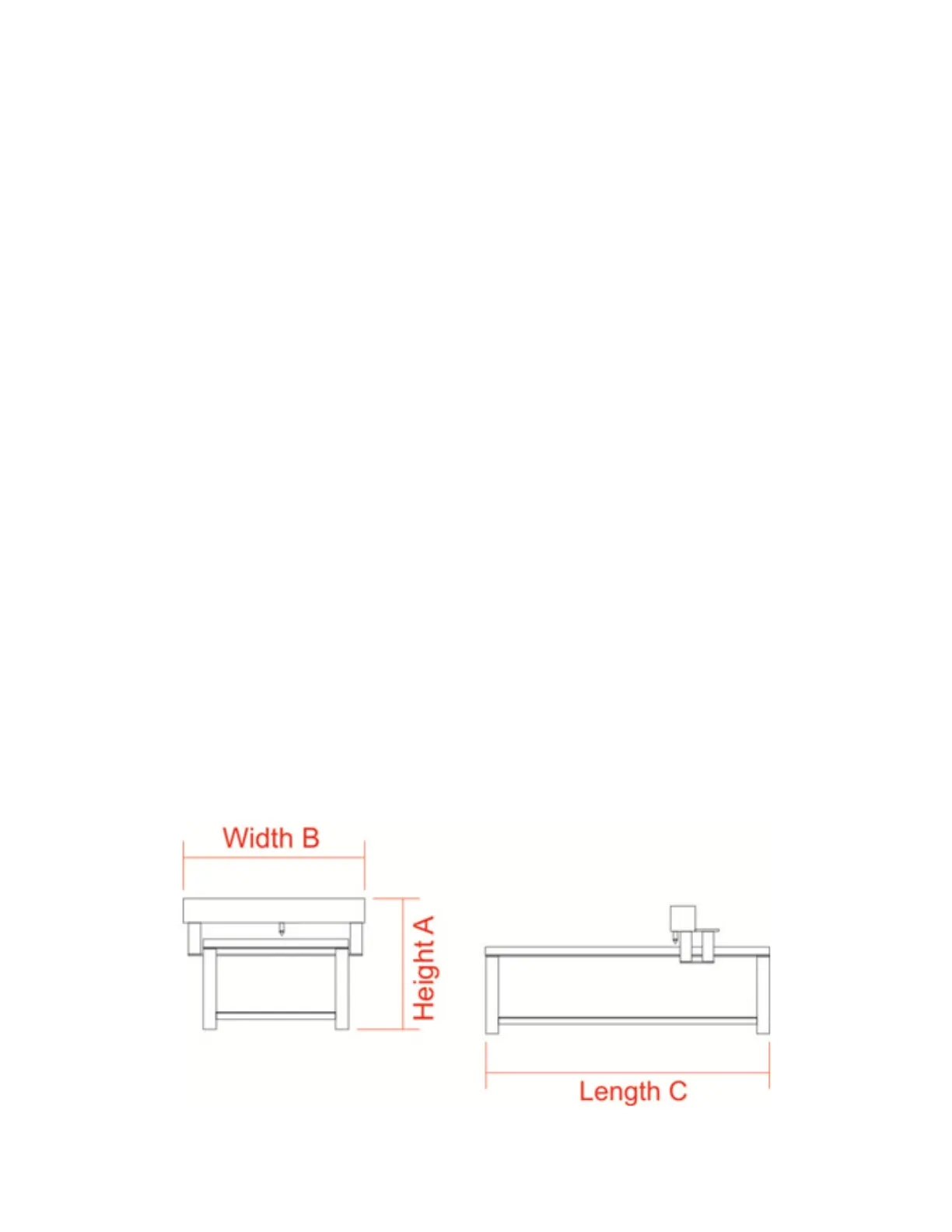

Material Handling, Floor Space and Leveling

The center of gravity is located at the center point of the crate. A forklift with extensions may be

needed to move the wooden crate the machine is shipped in. The chart below shows the dimensions

and weight of the laser machine.

Approximately 2 – 6 feet of clearance around the machine is needed to safely operate and perform

maintenance on the laser system. Additional space will make loading/unloading of materials even

easier.

10

Loading...

Loading...