Maintenance and service procedures of the laser beam optics assembly (cleaning and maintenance of

the lens and mirror) are to be conducted only by personnel who are familiar with laser safety and

with the potential laser hazards from the product.

Turn off the laser and close the shutter during lens and mirror cleaning, as operation of the laser

without the lens or mirror installed can result in a potential laser hazard from the invisible output

beam, even at distances of hundreds of feet away from the system.

Daily

1. Check for any frayed wires or leaking water lines.

2. Motion of table and laser should not interfere with any objects.

3. Keep vacuum table hoses suspended so they do not catch on edge of the system or any other

objects. This may cause motion of the table to be irregular.

4. Verify that air is coming from the nozzle. If not, turn on the air compressor and turn up the air

pressure to desired level.

5. Clean system after each days use. This includes wiping dust and debris from Teflon coated lead

screw with a clean, dry, soft cloth. DO NOT clean Teflon coated lead screw with any chemical as

this will cause flaking of the Teflon coating. Clean any dust and debris from the rest of the

system including power supplies and any other components.

6. Replace paper table covering as needed with thin paper. Newspaper roll remnants work well for

this.

7. Shut off power to the laser system each day.

Weekly

After starting the laser system, check the water level in the chiller unit (100 watt and above). Make

sure all chiller filters are free of dust and debris.

Note: Refer to maintenance section of your chiller manual for complete description of your chillers

maintenance schedule. Also, refer to your laser manual for additional information on required coolant

additive and mixture ratio.

Remove the 1” aluminum honeycomb and the 1” aluminum Ecolite from the vacuum table top. Clean

the top honeycomb, Ecolite and bottom of the vacuum table with degreaser to remove any debris or

water material buildup. If there is any waste material debris stuck in the honeycomb or Ecolite, use a

portable vacuum cleaner to clean it.

Monthly

Top Gantry Rails

Use a good grade of 10W30 automotive oil to lubricate

the bearings on the rails once very month. This may be

required more often with heavy use of the laser system.

Wipe rails with a clean, dry cloth before lubricating the

bearings.

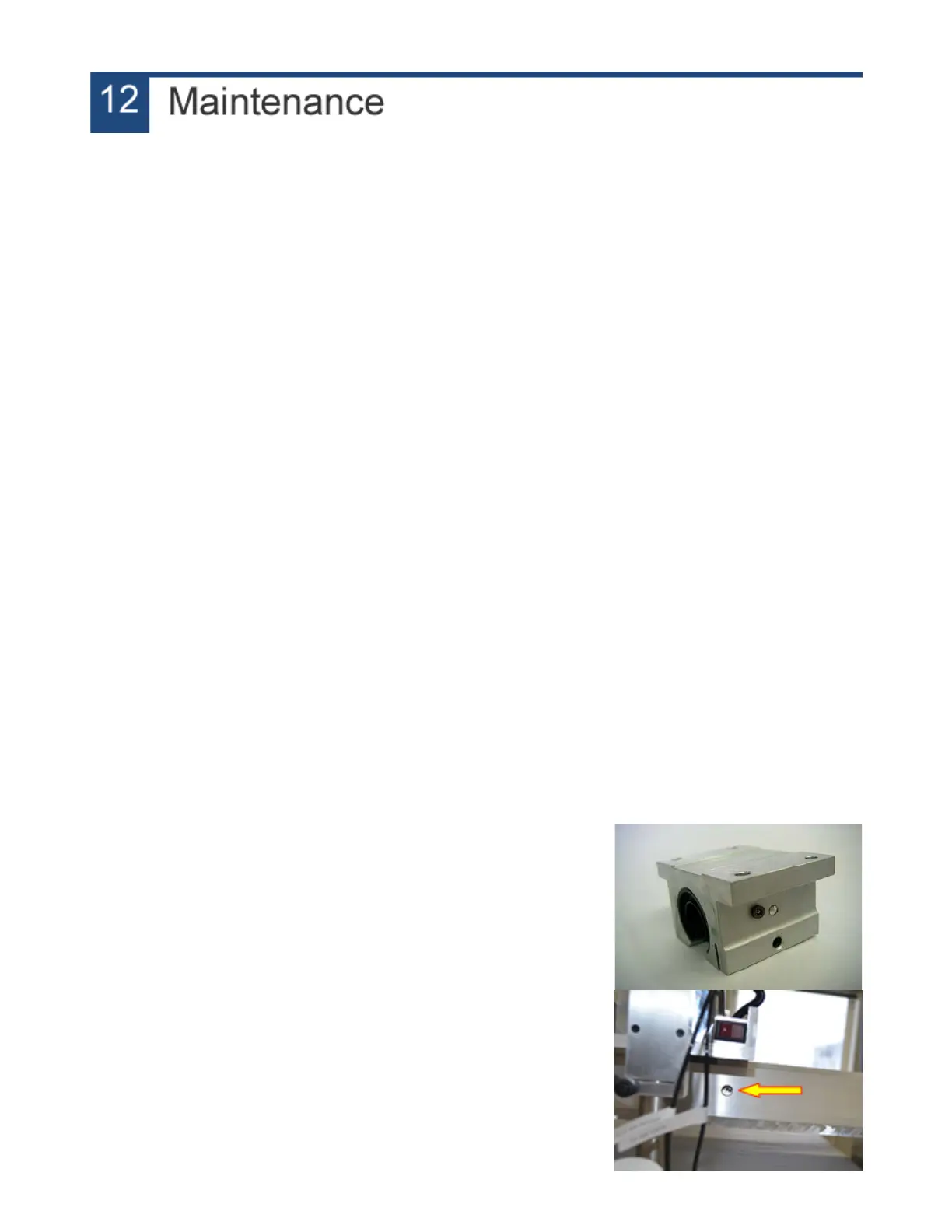

The laser must be positioned so that the hole at the front

of the gantry allow access to the oil point. See the photo to

right for a example of this. Use the special tip

of the oil can (provided) to insert the oil Zerk on the

bearing block. Pump the can several times.

57

Loading...

Loading...